The Special Valve Machine is mainly used in processing Valve(Butterfly valve/Gate valve/Ball valve/globe valve,etc..),Pump body, Auto parts, Construction machinery parts etc.

It work for many differenct processing,such as: End face,outer circle, front edge,Inner hole, grooving, Screw thread, Bore-hole and Sphere. It can realize automation, high precision, multi variety and mass production.Widely used in the valve industry.

About the valve industry

Valves are pipeline accessories used to open and close pipelines, control flow, adjust and control the parameters (temperature, pressure, and flow) of the conveying medium. According to its function, it can be divided into shut-off valve, check valve, regulating valve, and so on.

The valve is a control component in the fluid conveying system. It has the functions of cut-off, regulation, diversion, prevention of reverse flow, stabilization, diversion or overflow, and pressure relief. Valves used in fluid control systems, ranging from the simplest shut-off valves to the various valves used in extremely complex automatic control systems, have a wide range of varieties and specifications.

Valves are widely used in various fields. Mainly petroleum, metallurgy, electric power, water conservancy, urban construction, fire fighting, machinery, coal, food, etc.

Availability

What are the advantages of Special Valve Machine in the valve industry

√Drilling adopts a multi-axis type, and the efficiency is improved several times.

√Achieve two or three heads processing at the same time during processing to realize the standardization and high efficiency of pump pipe valve processing.

√Exclusive patented numerical control system, fully automated operation.

Our recommended Special Valve Machine

Our recommended Special Valve Machine

1.Machine body

The Machine body is made of overall high-quality gray iron casting, rough machining, finishing, and three tempering aging treatments to fully eliminate residual stress. The surface of the guide rail

It adopts super-audio frequency quenching treatment and is processed by high-precision guide rail grinding to ensure the accuracy, rigidity, and stability of the machine tool. √

2.Special Valve Machine

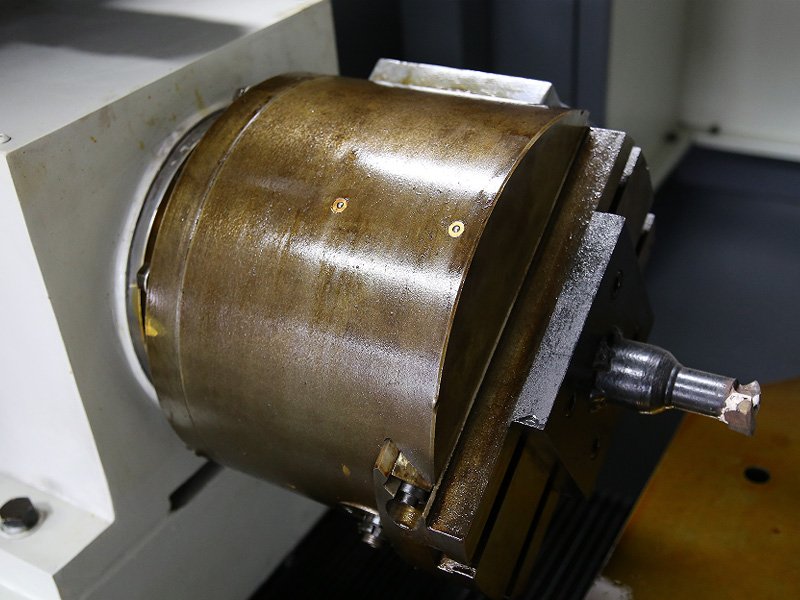

Head Box

The Head box is made of high-quality castings, and the main shaft is made of 20GrMnTAi, which has been forged, quenched, and tempered, carburized and quenched, and added by a high-precision internal and external cylindrical grinder.

The bearing adopts high-precision double-row cylindrical roller bearings to ensure the rigidity and precision of the spindle. The main shaft adopts a three-stage speed change with a high-power motor to achieve low speed

Large torque, can bear the heavy cutting load, improve processing efficiency. √

7. Centralized lubrication device

The lubrication system is equipped with a Nanjing Beqier progressive lubrication device, which regularly pumps the lubricating oil into the lubrication place of each moving part, eliminating the tedious manual operation.

Improve the service life of the machine tool. √

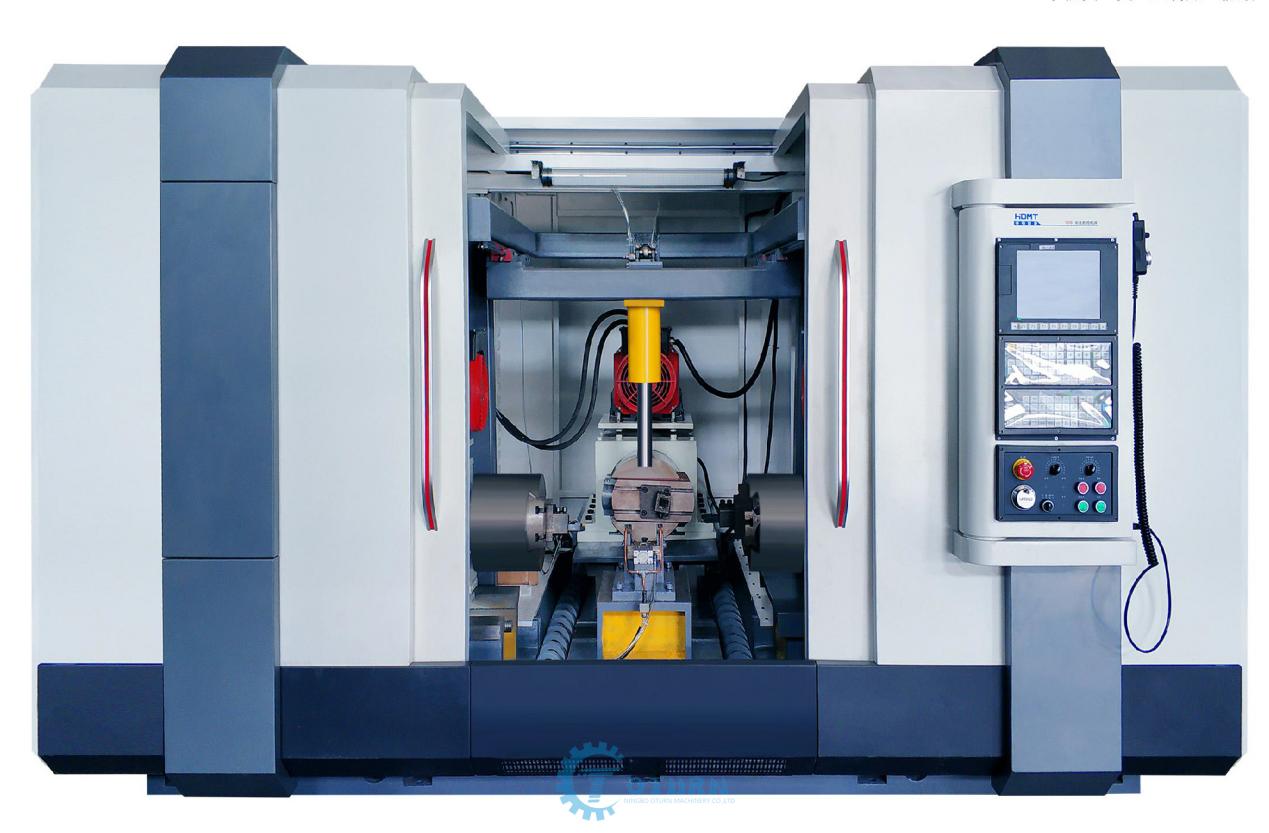

Two-head CNC Machine

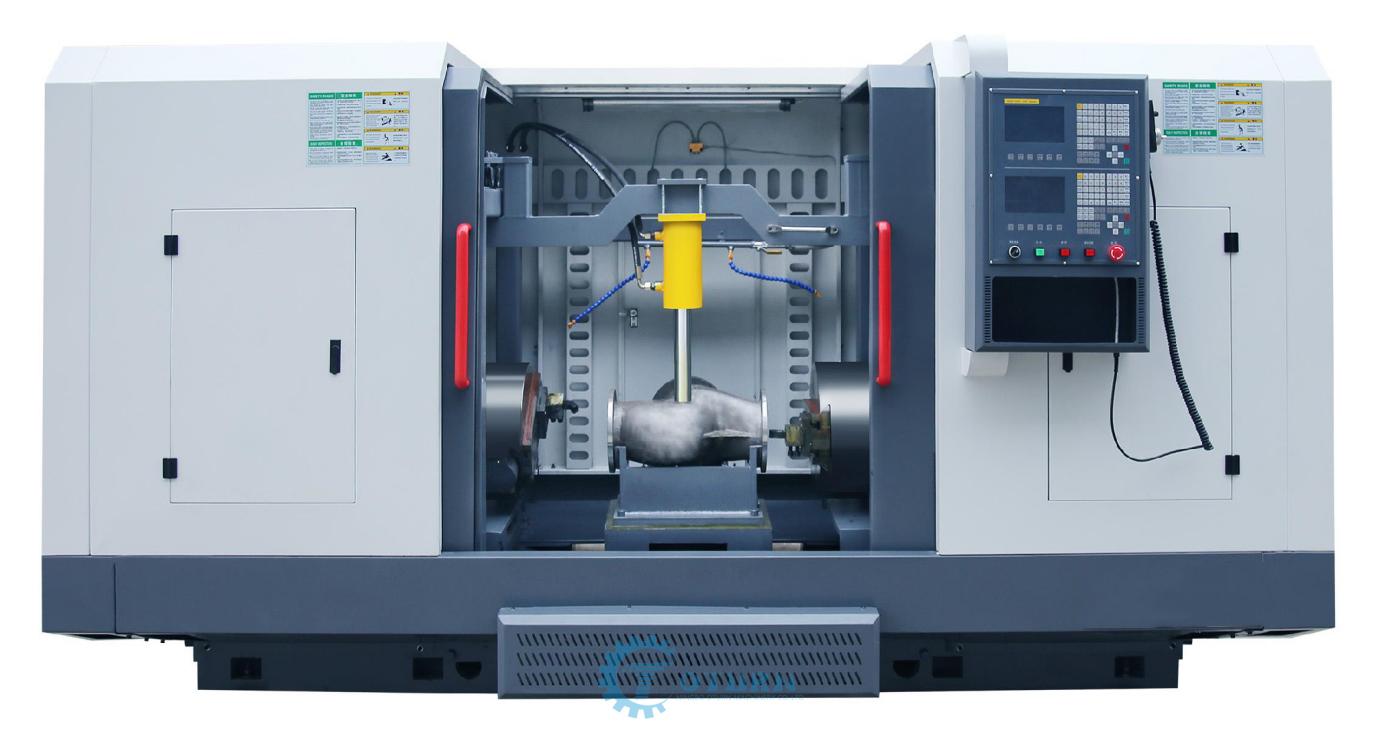

Butterfly valve special machine

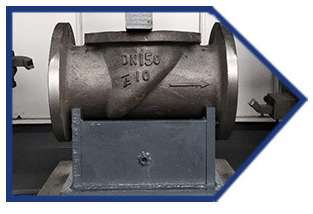

HDCX800 turning-milling composite machining center, butterfly valve special processing machine tool is mainly used in butterfly valves and the zero

For the processing of parts, engineering machinery and other parts, the end face, outer circle, spigot, inner hole, groove, thread, taper hole and spherical shape of the workpiece can be processed.

Turning. The processing process is controlled by the GSK CNC system, which can realize automation, high precision, multi-variety, and mass production.

main feature

1. The HDCX800 Special Valve Machine are all controlled by the GSK CNC system, which can be realized by dual-axis linkage.

Processing of taper holes, threads, and spherical processes. Its CNC system is compatible, powerful, and easy to operate.

2. The guide rail of the feed slide is made of high-quality gray cast iron, which has been subjected to three tempering aging treatments after roughcasting and finishing to fully eliminate residual internal stress.

The surface adopts super-audio frequency quenching treatment and the hardness reaches HRC55. The precision, rigidity, and stability of the machine tool are guaranteed by high-precision rail grinding.

3. The transmission parts are driven by precision ball screws and interpolation measures are used to eliminate gaps, ensuring smooth transmission and processing of the machine tool.

4. The powerhead adopts a three-stage manual transmission with a high-power motor to achieve low-speed and high-torque, can withstand heavy cutting loads, and improve processing efficiency.

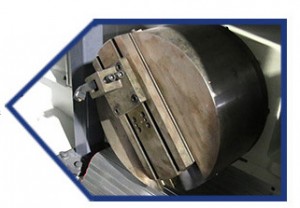

5. The tooling adopts hydraulic automatic clamping to improve efficiency and reduce personal labor intensity.

6. HDCX800 Special Valve Machine, butterfly valve special processing machine tool adopts centralized lubrication to ensure that each moving part is fully lubricated and improve the machine tool.

Special Valve Machine Structure

Power Head

The power headbox body is made of high-quality castings, and the main shaft is made of 20GrMnTAi material, which is processed by forging, quenching, and tempering, carburizing, and quenching, and high-precision internal and external cylindrical grinders.

The bearing adopts NN30 series high-precision double-row cylindrical roller bearings to ensure the rigidity and precision of the spindle.

Worktable

The worktable is a special workbench specially designed according to the processed parts. The positioning blocks and positioning pins are all quenched to ensure the reliable positioning of the workpiece.

Workpiece clamping adopts manual clamping to improve processing efficiency and reduce personal labor intensity. And the worktable can be rotated 180 degrees, one-time clamping, one-time Complete all processes.

Automatic tool change tool magazine

Fully automatic CNC tool changer tool magazine, which can hold 16 tools, 20 tools, 24 tools, etc., which are automatically controlled by the system, with fast tool change speed and precise accuracy.

- Power head

The power head adopts an exclusive patented motor + screw structure, which has the characteristics of high precision, high rigidity, and long life.

- Tooling

-

The tooling is special tooling specially designed according to the parts to be processed. The positioning blocks and positioning pins are all quenched to ensure the reliable positioning of the workpiece. The workpiece is clamped by hydraulic clamping, which improves the processing efficiency and reduces the labor intensity of the workers.

- Electrical cabinet

The electrical cabinet adopts an independent closed type, with built-in control system, frequency converter and airport control electrical components, and is equipped with air-cooling devices to ensure that the electrical components of the machine tool work normally and do not enter dust.

- CNC Control System

It has the functions of multi-channel control technology, five-axis machining, high-speed and high-precision, turning and milling, synchronous control and other high-end CNC control.

Equipment selection:

CNC control

cooling control

Automatic chip conveyor

Half protection/full protection

For different types of valves, different processes are processed. For example, production activities and various technical preparations need to be made before processing. Engineers need to make relevant preparations according to the process design of the product itself and the special process equipment manufacturing of Huadian valve plane. The valve blank parts can be designed by sand casting, precision casting or arrow wax casting when manufacturing. For forging or welding processes, it is necessary to design according to the relevant blank conditions.

The valve processing procedures are complex, and the added value of the product is low. The advantages of using general-purpose or CNC machine tools cannot be reflected. The complete processing of a valve even requires the combination of multiple machines to achieve the processing effect. Every time you change a size or variety, you need to adjust the machine tool, and then transfer the completed process from the previous process to the matched machine tool in the next process. This not only increases the manufacturing cost, but also wastes a lot of time cost. Generally, workpieces that require relatively high precision, because of multiple clamping changes, increase the precision error of the workpiece. So the benefits of the valve plane are self-evident.

For example, for gate valves, the turning of three-sided flanges can be done on a single machine. At present, the HDMT valve special machine can simultaneously process two or three sides of the valve flange at one time, which is simple and efficient, while traditional production Only one flange of the valve can be processed at a time, which is time-consuming and labor-intensive. In the same way, the flange drilling on three or two sides of the valve is also based on the same principle, which not only improves the efficiency, but also reduces the position tolerance of the hole.

The operation of the valve special machine is also very simple, all models have realized the automatic design, only need to input the parameters. This greatly reduces manual operations, reduces labor costs, and saves time and effort. If there is an overload or some other problem occurs during the production process, the machine will promptly give an alarm or automatically shut down, so as to avoid machine damage to the greatest extent.

After the valve plane is finished, the operator should turn off the related power supply, do a good job of cleaning, and use professional lubricants to repair and maintain the valve plane. There are many things that need to be paid attention to during the operation of the special valve machine. The special valve machine cannot perform such tasks as tool adjustment, inspection and removal during the operation. During the whole process of the operation of the special valve machine, the relevant staff and operators must not leave their jobs, and must do a good job of relevant supervision. Tools such as workpieces, fixtures, and knives must be clamped firmly, otherwise some problems with workpiece movement will occur. Poor operation can cause unnecessary injuries. If the knife is broken or broken, it needs to be replaced in time. In the process of normal operation, we cannot directly touch the surface of the workpiece with our hands, nor can we directly remove dangerous objects such as cutting with our hands. This will not only hurt our hands, but also cause iron filings to fly. The accident into the eyes. During the working period of the special valve plane, you should wear the corresponding overalls, wear the work cap, and be sure to stuff your hair into the work cap. When loading and unloading large workpieces, try to use lifting equipment, so that the entire operation can coexist more professionally, and the safety performance will be higher.

Post time: Sep-22-2021