News

-

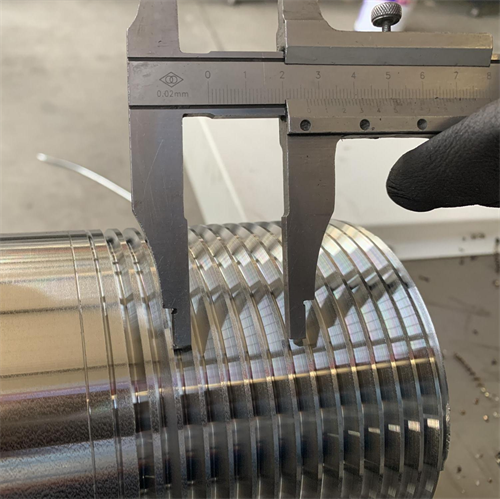

Methods Of Tool Setting For CNC Lathe

One of the often utilized CNC machine tools is the CNC lathe. It can be used for grooving, drilling, reaming, reaming, and boring. It is primarily used for cutting internal and external cylindrical surfaces of shaft parts or disk parts, internal and external conical surfaces of arbitrary cone ang...Read more -

Introduction and advantages of valve processing lathes

In our firm, industrial valve processing lathes are also known as double- or three-sided valve milling. The valve’s high-efficiency and high-precision machining needs are met. The needs of simultaneous turning of three-sided or two-sided flanges in one clamping can be met by the special mac...Read more -

How to choose tools of machine in Russia? Can it improve processing efficiency(2)?

When choosing a tool that is more suitable for you, you should consider the following aspects: 1. The tool performance of the material to be processed The tool material is the fundamental factor that determines the tool performance of the tool, which has a great influence on the processing effici...Read more -

How to choose tools of machine in Russia? Can it improve processing efficiency(1)?

As the “teeth” of CNC machines, tools play a vital role in the process of machine processing. The tool not only has a direct impact on the machining efficiency of the machine, but also greatly affects the machining quality of the parts. Compared with the traditional machining methods,...Read more -

Routine Care and Maintenance of Chip Conveyors in Mexico

First, the maintenance of the chip conveyor: 1. After the new chip conveyor is used for two months, the tension of the chain needs to be readjusted, and it will be adjusted every six months thereafter. 2. The chip conveyor must work at the same time as the machine to...Read more -

What should be paid attention to when operating the machining center light machine in Turkey?

1. The optical machine of the machining center should be operated by correspondingly trained and qualified personnel, check whether the liquid level of the hydraulic oil tank is above the specified oil level line, and the working pressure of the air source processing device is about 0.6MPa; 2. Cl...Read more -

Why doesn’t the electro-spindle run after it’s turned on? Let’s take a look at effective solutions

The electric spindle of Horizontal lathe has the advantages of compact structure, light weight, low inertia, low noise and fast response. The servo spindle of the lathe machine has high speed and high power, which simplifies the design of the machine tool and is easy to realize the spindle positi...Read more -

For routine maintenance of heavy duty horizontal lathe machines do so in Eastern Europe

The maintenance of the heavy-duty horizontal lathe machine refers to the operator or maintenance personnel, according to the technical data of the machine and the relevant requirements and maintenance rules for start-up, lubrication, adjustment, anti-corrosion, protection, etc. A series of operat...Read more -

Check these details before using a horizontal lathe in Southeast Asia

A horizontal lathe is a machine tool that mainly uses a turning tool to turn a rotating workpiece. On the lathe, drills, reamers, reamers, taps, dies and knurling tools can also be used for corresponding processing. 1. Check whether the oil circuit connection of the lathe is normal, and whether t...Read more -

Let’s take a look at the advantages of 5-axis machining center in the new energy market!

5-axis linkage machining center, also called 5-axis machining center, is a machining center with high technological content and high precision specially used for machining complex curved surfaces Instruments, high-precision medical equipment and other industries have a pivotal influence. The 5-ax...Read more -

Do you need to wear gloves when doing machining in 2022?

Nowadays, many workers engaged in mechanical processing wear gloves on their hands when working, in order to prevent the flash or iron chips on the edge of the product from cutting their hands. It is true that people who do machining work don’t earn much, and they end up with a lot of oil,...Read more -

What is the typical product market situation of the drilling and boring machine industry in Asia(2)

Through the investigation of industry enterprises, we learned that the current industry enterprises generally face the following problems: First, operating costs are too high. For example, the price of raw materials has risen sharply, which has led to an increase in the procurement cost of enter...Read more -

What is the typical product market situation of the drilling and boring machine industry in Asia(1)

In recent years, the market demand has gradually shifted from traditional products to products with the characteristics of numerical control, intelligence and greening. 1. Drilling machine product market situation At present, users’ requirements for drilling machine products show different...Read more -

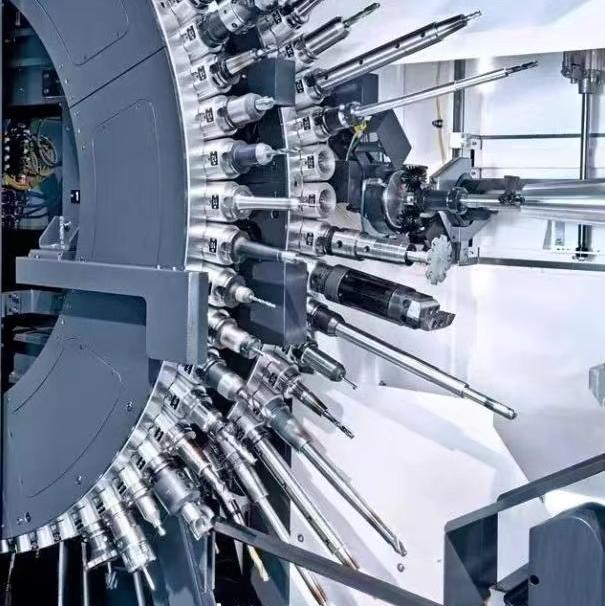

Edit Many different tools are often used in the machining process of high-precision CNC lathes

High-precision CNC lathes can achieve high-precision, high-rigidity, and high-speed motion. The spindle of the high-precision CNC lathe is a sleeve-type unit spindle. The spindle material of high-precision CNC lathe is nitrided alloy steel. The reasonable bearing assembly method of the high-preci...Read more -

A brief introduction to the accuracy standard of horizontal lathe machining

A horizontal lathe is a machine tool that mainly uses a turning tool to turn a rotating workpiece. On the lathe, drills, reamers, reamers, taps, dies and knurling tools can also be used for corresponding processing. The method often used in CNC horizontal lathe control engineering is to first est...Read more -

What to pay attention to when choosing an automatic CNC lathe in Russia

A CNC lathe is an automated machine tool equipped with a program control system. What aspects should be paid attention to when choosing a CNC lathe? The process requirements of the parts are mainly the requirements of the structure size, processing range and accuracy of the parts. According to th...Read more