The CNC machining center is a kind of CNC machine.Machining centers are also divided into horizontal machining centers and vertical machining centers.

The spindle axis (Z-axis) of the vertical machining center is vertical, which is suitable for processing cover parts and various molds;

The spindle axis (Z-axis) of the horizontal machining center is horizontal. Generally, it is equipped with a chain-type tool magazine with a larger capacity. After a clamping. Automatically complete multi-surface, multi-process processing, which is mainly used for the processing of box parts.The machine used for five-axis machining is usually called a five-axis machine or a Five Axis Machining Center. Five-axis machining is often used in the aerospace field to process body parts, turbine parts, and impellers with the right curved surfaces. The five-axis synchronous CNC machine can process different sides of the workpiece without changing the position of the workpiece on the machine tool, which can greatly improve the processing efficiency of prismatic parts.

CNC machining centers are mainly used in the following industries:

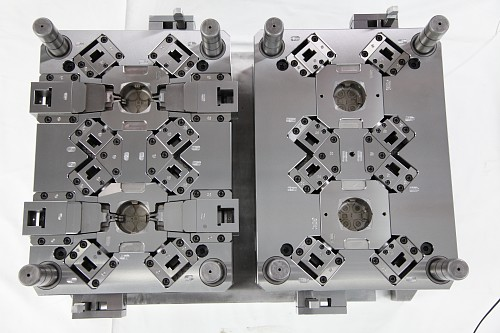

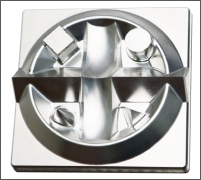

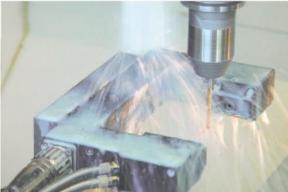

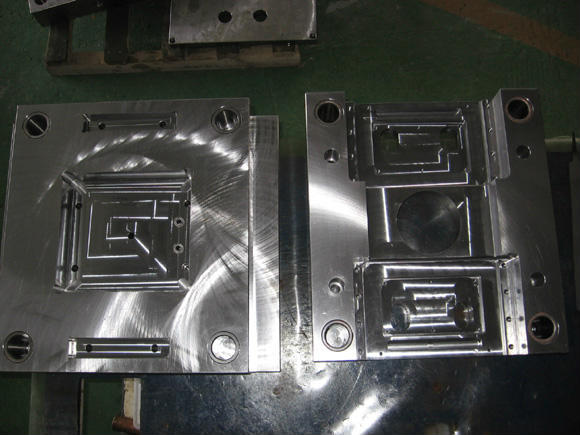

1. Mould

Mold industry introduction:

Molds, various molds, and tools are used in industrial production to obtain desired products by injection molding, blow molding, extrusion, die-casting or forging molding, smelting, stamping, and other methods. In short, a mold is a tool used to make molded objects. This tool is composed of various parts, and different molds are composed of different parts. It mainly realizes the processing of the shape of the article through the change of the physical state of the formed material.

Mold

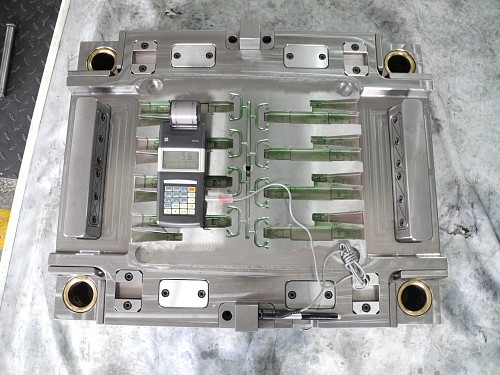

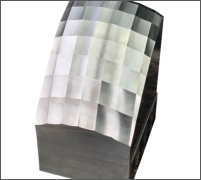

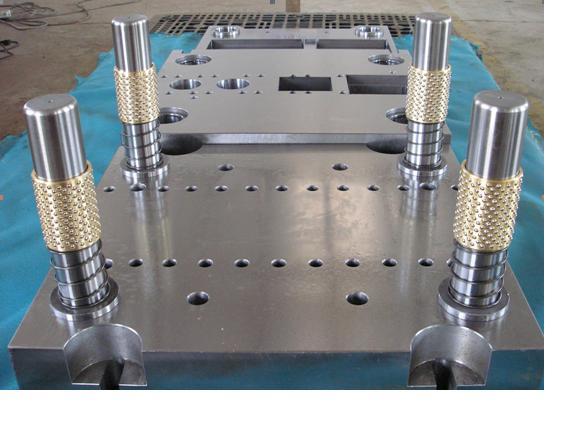

2.Box-shaped parts

Parts with complex shapes, a cavity inside, a large volume and more than one hole system, and a certain proportion of the length, width, and height of the internal cavity are suitable for CNC machining of machining centers.

Box-shaped parts

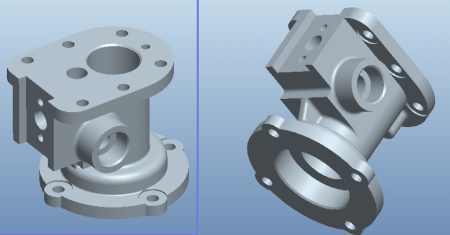

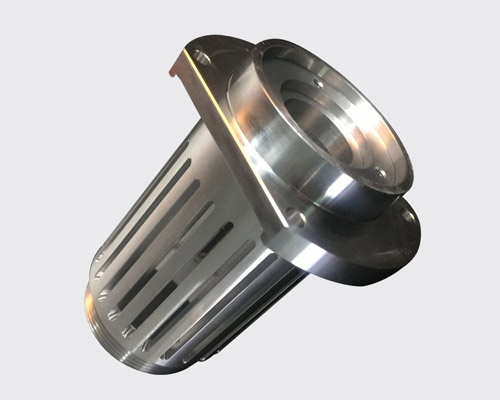

3. Complex surface

The CNC machining center can be clamped at one time to complete the processing of all side and top surfaces except for the clamping surface. The processing principle is different for different models. The spindle or worktable can complete the processing of 90° rotation with the workpiece. Therefore, the machining center is suitable for processing mobile phone parts, auto parts, and aerospace materials. Such as the back cover of the mobile phone, the shape of the engine and so on.

Aerospace parts

Auto parts

High Speed CNC Milling Machine

Ball Screw & Linear Guiderails

3 Axis ball screw and linear guide rail are equipped with central automatic lubrication device. 3 Axis adopt precision ball screw.

3 Axis designed with 4~6 pcs sliding blocks to ensure the movement accuracy and stability of the machine ,extend the service life of the machine 3 Axis Adopt roller linear guide rail, which ensures the movement precision of machine and makes the machine play a higher rigidity.

High rigidity structure design

The CNC milling machine tool main parts such as Machine bed, beam and the columns are made of high-grade MEEHANITE cast iron. And after several aging treatment,

effectively eliminate the internal stress, to ensure that the CNC VMC machine has a better accuracy.

And after several aging treatment, effectively eliminate the internal stress, to ensure that the machine has a better accuracy.

The arrangement of stepped linear guide rail for the beam (the top surface of the beam and the front of the beam), combined with the design of

the super-wide saddle, ensures the processing effect of the spindle with high precision and high stability.

Special Spindle Box Design

The special head design makes the z-axis movement more stable.The lightweight design makes it move more quickly horizontally and vertically to achieve the purpose of rapid response.

Better user experience

Some vertical CNC milling machine can choose the full enclosed sheet metal, to provide users with a safer, environmentally friendly environment. The semi-rotating operation box and others humanized designs provide users with convenient and safe operation experience.

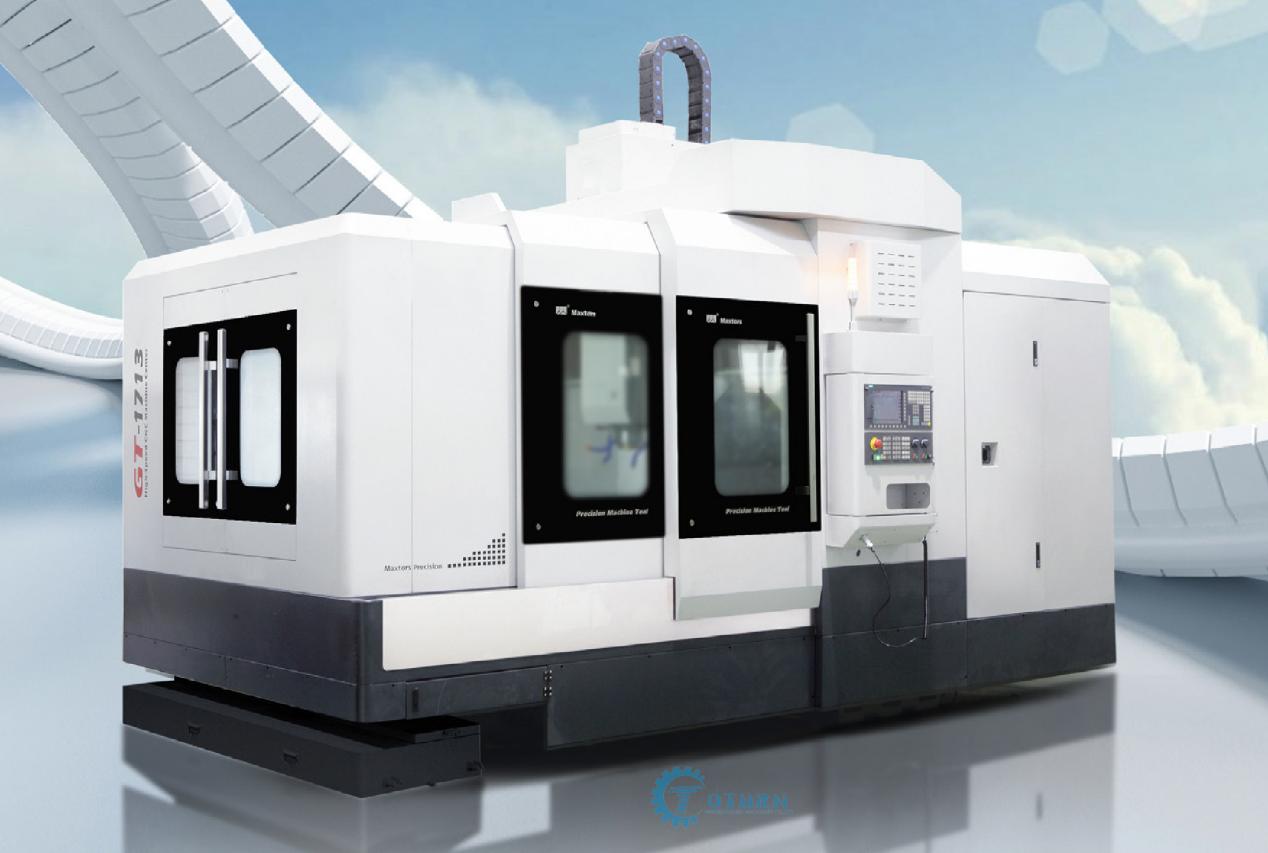

High Speed Machine Center

This High Speed Machine Center Keeping the strong rigidity, structure symmetry and good stability on the basis of traditional gantry machine foundation frame, introduces the international advanced dynamic rigidity design concept and optimizes the design of the moving parts.This machine has strong rigidity and fast response, which can meet the needs of high-precision aviation parts processing and various high-precision mold processing .

3 Axis standard with Linear Scales, Positioning more accurate.

Laser Tool Probe (Optional)

Standard with 21T ATC/Tool Magazine it can perfectly improve the efficiency of machining preparation.

3 Axis Roller Guiderails ,high precision and low friction coefficient, which can reduce Machine

creeping phenomenon at low speed, good positioning accuracy and high dynamic response characteristics.

Adopts Built-in type High Speed Motorized

Spindle,Max.20000rpm,best for High Precision & Good Surface Quality Processing.

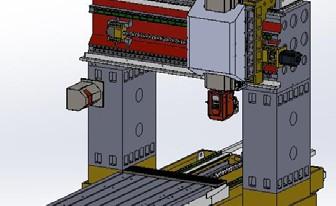

Two columns and crossbeam are whole part makes the CNC Gantry Milling Machine has a better rigidity, long-lasting stability and excellent shock absorption performance. Equipped with high performance controller, servo motor, high precision guide way/screw makes it a high-efficiency and high- precision CNC Gantry Milling Machine. Z axis is equipped with nitrogen booster clinder to reduce the burden of motor. So the CNC Gantry Milling Machine can focus on the milling capacity. HSK high-speed spindle is optional which can improve the milling efficiency. Scientific management and strict detection equipment ensure the precision and quality of the machine. CNC controller like Siemens, Fanuc or Mitsubishi can be selected to fully meet customers' use habits.

This CNC Gantry Milling Machine is widely used in auto-parts, aerospace, mould, engine,household appliances and other fields.

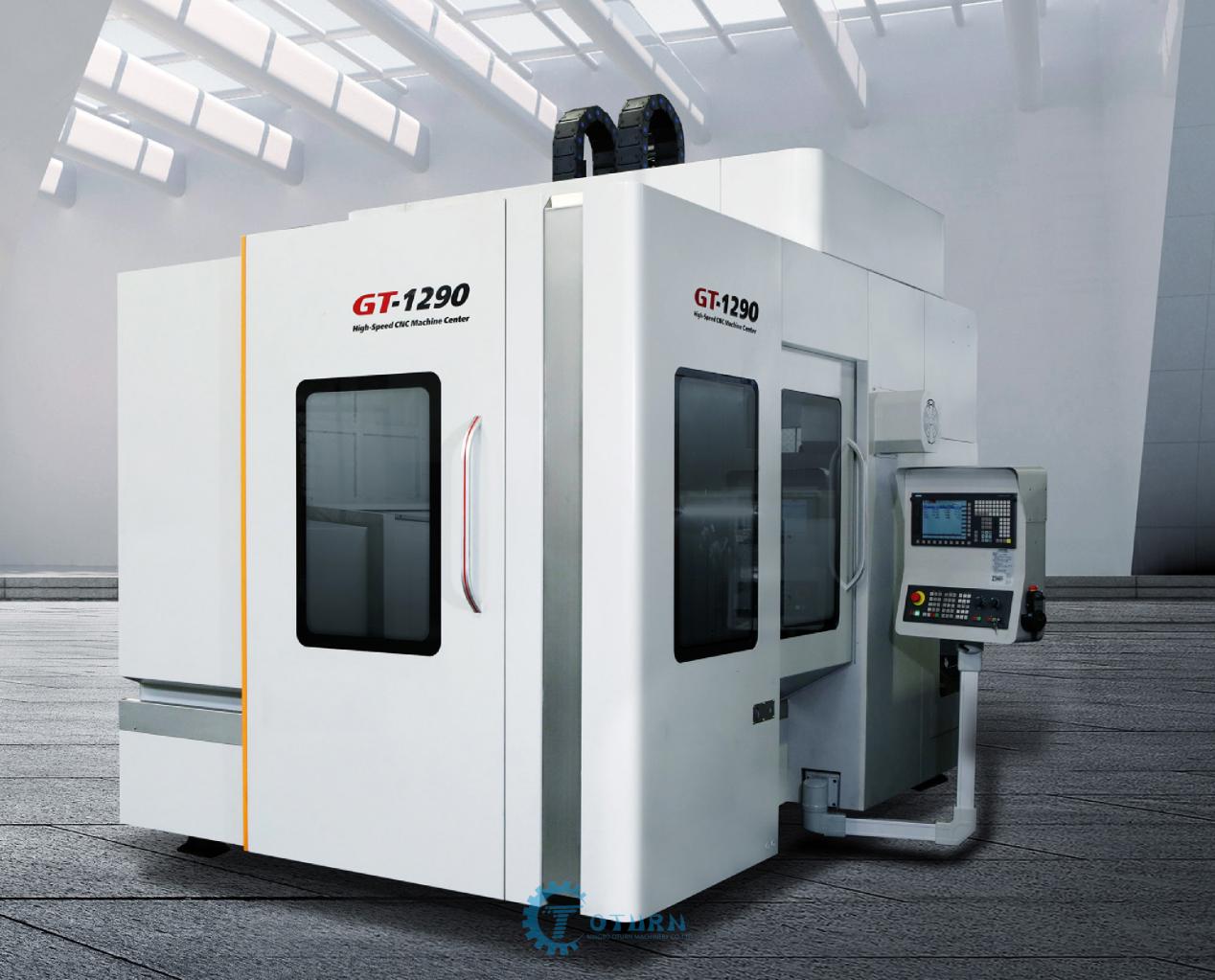

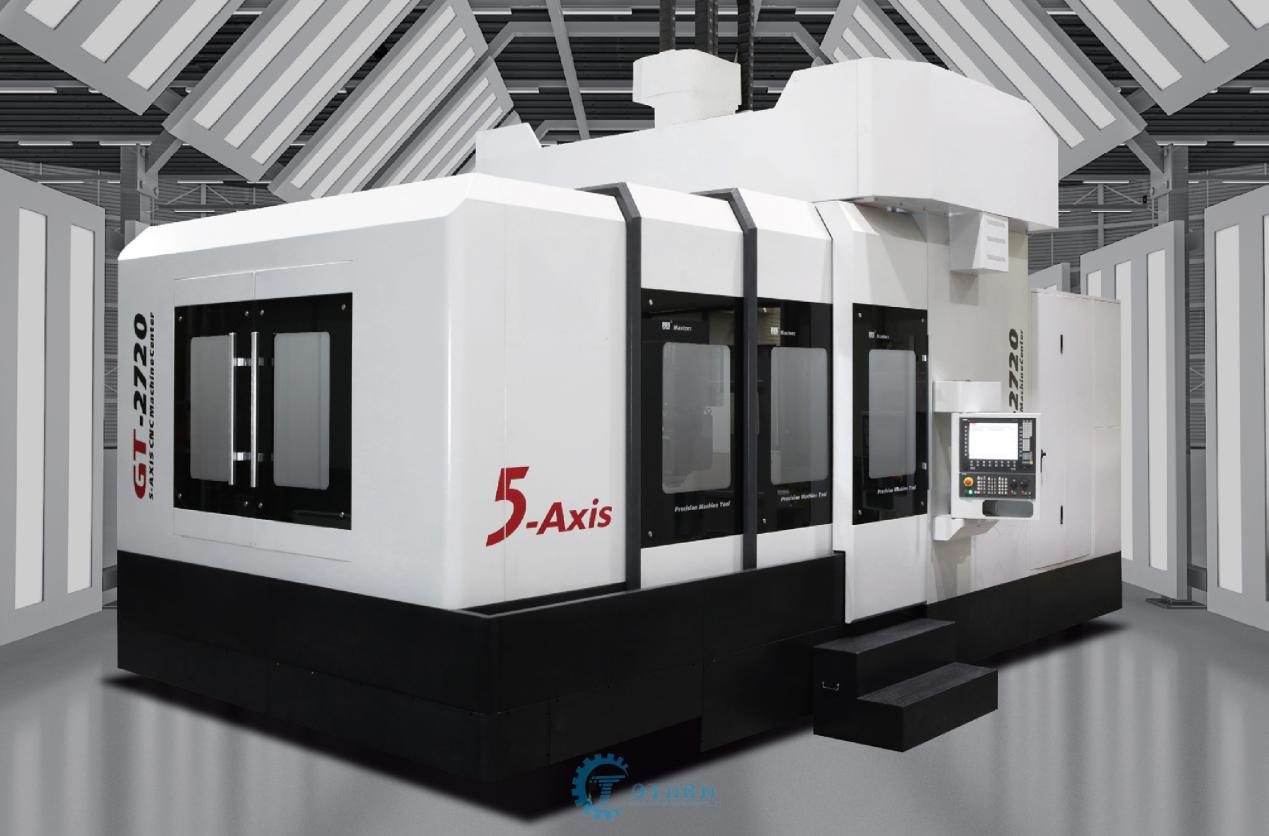

Double Column Type 5 Axis Machine Center

This machine is Double Column Type 5 Axis Machine Center,Keeping the strong rigidity, structure symmetry and good stability on the basis of traditional gantry machine foundation frame, introduces the international advanced dynamic rigidity design concept and optimizes the design of the moving parts.This machine has strong rigidity and fast response, which can meet the needs of high-precision aviation parts processing and various high-precision mold processing .

The distance from Spindle Center to guide rail surface is short.with Good Structure Rigidity Beam,effectively improve the movement stability of spindle.Z - axis with 4 pieces guderails design structure, Overall structure rigidity significantly enhanced.

Adopt high-speed Built-in spindle,max 20000RPM, which can provide perfect solution for high precision machining and high surface quality machining.

3 Axis standard with Linear Scales, Positioning more accurate.

The vertical and horizontal CNC machining center is a very important link in the technical level of the entire industry. In recent years, customers in the international market have changed their perceptions of China's machining centers. The assembly level, accuracy and stability of the machining center, and appearance design have been greatly improved, and it is already comparable to Taiwan, Japan and South Korea brands. Coupled with China's specific market volume, manufacturing and production costs are much lower than those of Taiwan, Japan and South Korea, making the processing center recognized by customers in the European and American markets year by year, which also reflects the improvement of China's comprehensive economic strength.

Nevertheless, we still have a certain gap between our higher-precision CNC machining centers and the machines in the European and American markets, and even some of our core accessories and technologies still need to be imported. The machining centers of some developed countries have already achieved high-precision, high-speed, composite multi-function, multi-axis linkage and other functions. These are the areas where there is still a gap between China and developed countries in Europe and the United States. The development of China's five-axis five-link machining center is still restricted by foreign numerical control systems, so the performance and technical level of some high-tech products cannot meet the requirements, which makes some products and core components have to rely on imports. Therefore, we have seen that some Chinese CNC machining center manufacturing plants are in order to gain much market space on the international stage, and they have also stepped up to make some changes. This is the mission of the Chinese generation.

At present, our customer groups include shipbuilding, textile industry, automobile manufacturing, aerospace industry, etc. These customers have high requirements for the processing speed, technical accuracy and production efficiency of machine tools. There are stricter requirements on the configuration of the spindle. For example, the spindle speed is required to be above 12000rpm/min, and the moving speed is above 40m/min. For complex workpieces, especially curved surfaces with complex shapes, they have very high requirements for accuracy and efficiency. Multi-axis machining must be the preferred choice, such as small 5-axis 5-linkage machining centers and large 5-axis gantry machining centers.

With the gradual implementation of industry automation, machining centers and industrial robots have been used in combination, allowing the robots to bear some simple and repetitive labor, which can save a lot of production costs. Coupled with the stability of the robot and the machining center, the quality of the product is also guaranteed.

This year’s machining center development is deeply affected by the inability to supply CNC systems in a timely manner. At present, the CNC systems equipped in Chinese machining centers are almost all foreign brands, such as FANUC, MITSUBISHI, SIEMENS. And my country’s Taiwanese brands Syntec, LNC domestic brands GSK, KDN Although Huadong CNC etc. can basically realize the functions of well-known foreign brands, there are still some incapable functions that cannot be replaced.

As the integration of industrial innovation field and technology, processing center also marks the country's development level. As China becomes more and more important on the international stage, Chinese robots need to work together to improve China's overall level.

Post time: Sep-18-2021