The Oturn Center-Drive Lathe is an efficient, high-precision, and advanced manufacturing equipment, with several domestic leading technologies. The parts can be clamped once to complete the outer circle, end face, and inner hole of the two ends of the workpiece at the same time, and the parts can be clamped twice Compared with the traditional process of U-turn processing, the medium-drive lathe has higher production efficiency and higher coaxial precision of the processed parts. At present, our company has developed more than ten specifications of double-headed products and has been introduced to the market. Clamping The diameter ranges from φ5mm-φ250mm, and the processing length ranges from 140mm-2500mm.

Another type of product is a Double Spindle CNC Lathe, which is suitable for turning disc or short shaft parts with a diameter of Φ200mm and a maximum inner hole length of 120mm. The parts are automatically docked through dual spindles to complete all processing of the two sequences. The above two types of CNC lathes can be equipped with automatic loading and unloading and storage devices to realize fully automatic production.

The mid-drive CNC lathe is a non-standard customized CNC lathe, which belongs to special machine tools. The customer adopts a piece of equipment, cooperates with the technical application plan, effectively controls the cost, satisfies the customer's processing request well. Compared with the one-way machining of the traditional CNC lathe, the middle-drive lathe uses the headstock to perform bidirectional machining of the workpiece, and the theoretical machining efficiency is twice that of the traditional lathe. Especially for disk-type workpieces or shaft-type batch-processing workpieces that require relatively high coaxiality and are not easy to be clamped twice, the mid-drive CNC lathe is almost the only efficient and can guarantee the coaxiality and accuracy requirements. machine.

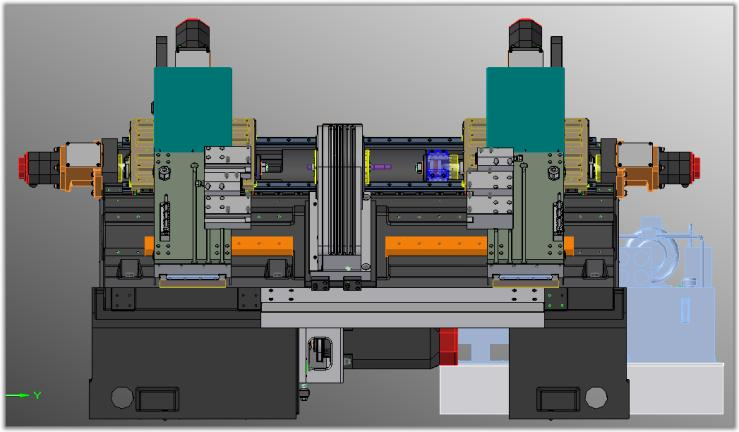

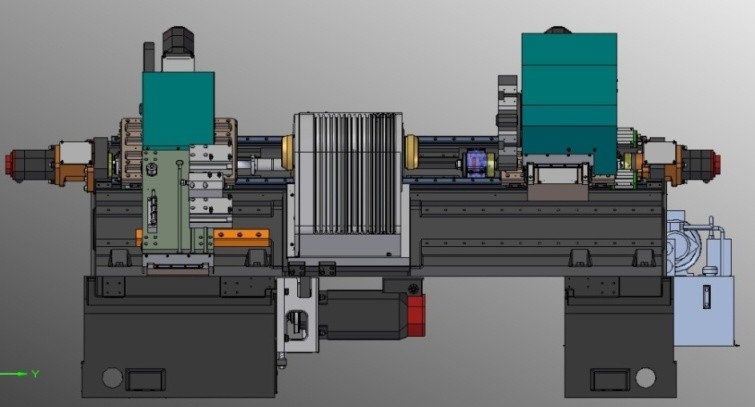

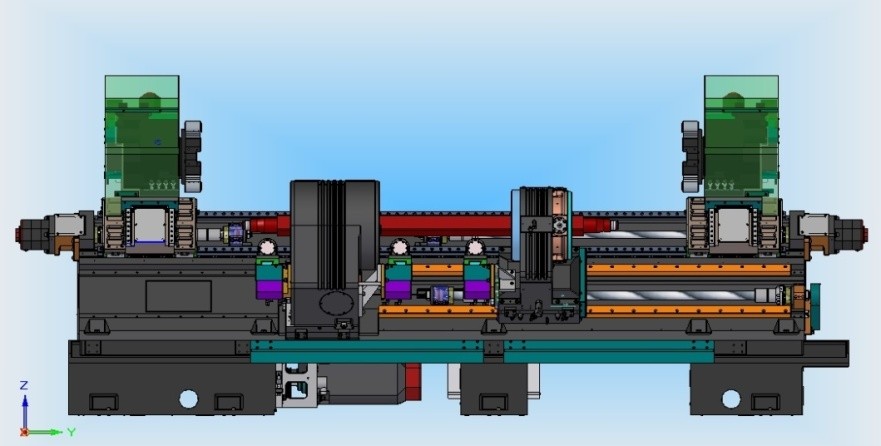

The double-head CNC lathe mainly has the following components: left and right sliding table, left and right large carriage, left and right longitudinal ball screws, left and right longitudinal servo motors, electrical appliances and numerical control system. Between the left and right sliding tables, there is a spindle seat fixedly linked to it. The spindle seat is equipped with a hollow spindle, a transmission box and a frequency conversion motor. Hollow main shaft, transmission box and frequency conversion motor. The left and right large carriages are equipped with horizontal left and right middle carriages. The left and right middle carriages are equipped with matching left and right horizontal ball screws and left and right horizontal servo motors.

Single/double headstock

Tool post: rotary/row tool/power

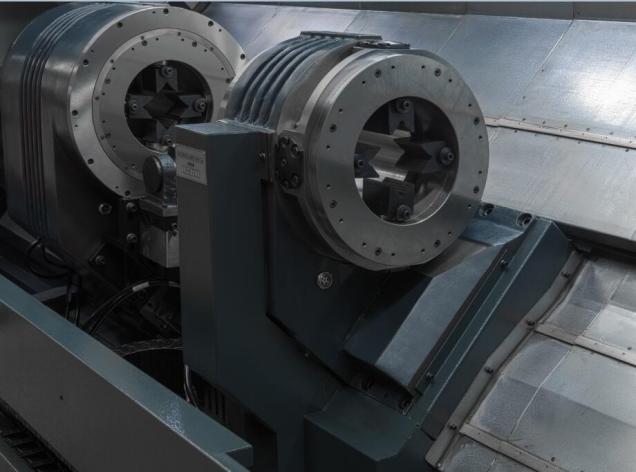

Hydraulic fixture: collet type, claw type

Multi-configuration/multi-function for selection

Advantages of Center-drive lathe

1. Concentration of processes, reducing the number of workpiece clamping times.

2. Once clamping, both ends will be processed at the same time.

3. Shorten the production process.

4. Equipped with loading and unloading devices and storage devices to realize fully automated production.

5. The workpiece is clamped in the middle position, the clamping is reliable, and the torque required to transmit the machine cutting is sufficient, and a large margin can be turned.

Machine introduction:

As China the best Center Drive Lathe Machine factory, we adopts 45° inclined bed layout, which has good rigidity and easy chip evacuation. The headstock with intermediate drive clamping function is arranged in the middle of the bed, and the two tool holders are arranged on both sides of the headstock. The rolling guide is adopted, and each servo feed shaft adopts a high-mute ball screw, and the elastic coupling is directly connected, and the noise is low, the positioning accuracy and the repeated positioning precision are high..

Equipped with a dual-channel control system, the two tool rests can be linked to the spindle at the same time or separately to complete simultaneous or sequential processing of both ends of the part. The machine tool adopts a modular design and can have a variety of structure, configuration, and function combinations according to your needs. There are two options for the knife holder, row knife type or turret type. The row knife holder has three sets of guide rails longitudinally, and four knives can be installed up and down.

Single spindle, left turret gang tool, right turret structure

Single spindle, left and right tool holders are gang tool structure

According to the blank condition, size, and shape of the part, the clamping method, axial length, through-hole diameter and clamping diameter of the spindle box equipped with each specification machine tool can be selected separately. Intermediate clamping and two ends are clamping. The collet-type headstock, the middle clamping, and the two-end clamping jaw-type headstock, there are extendable headstock, ultra-short headstock, high clamping accuracy headstock, and the clamping accuracy can reach 0.005mm. The length of the part can be equipped with a single headstock or double headstock.The headstock of the medium-drive lathe is fixed, and the sub-headstock can be moved axially (manually movable or servo-movable). It can also be used for two The spindle box is clamped to complete the processing of long parts, and it can also be used to only use the spindle box to clamp to complete the processing of short parts. The spindle box integrates the three components of the spindle system fixture, clamping, and oil cylinder. The structure is compact and the work is reliable.

The maximum machining length of the double headstock is 2500mm, and the maximum through-hole diameter of the headstock can reach Φ370mm. The clamping devices are all hydraulically driven, and the clamping force can meet the needs of the maximum turning torque. There are many options for the chuck if the diameter of the part is specified There are many, adopting the structure of installing the adjusting claw in the chuck, which is very convenient and quick to replace.

The Center Drive CNC Lathe can also be equipped with automatic loading and unloading devices and storage devices to realize fully automatic processing.

The mid-drive lathe is fully enclosed and protected, equipped with automatic lubrication and automatic chip removal devices, with good protection performance, easy operation and convenient maintenance.

Parts suitable for middle-drive lathe processing:

1. Auto parts:

Gearbox input shaft, gearbox output shaft, welded axle, steering rod, half shaft, shaft tube, shock absorber piston tube, trailer axle, torsion bar.

Gearbox input shaft

Gearbox output shaft

steering rod

Half shaft

Shock absorber

Shaft tube

2. Other mechanical product parts:

Motor shaft, spinning machine roller, bottle mold, oil drill pipe joint, water pump rotor shaft, printing machine drum.

spinning machine roller and Motor shaft

oil drill pipe joint and water pump rotor shaft

Glass mold And Printing machine drum

The main industries where medium drive lathes are applied:

1. Automobile industry:

Machining of gear shafts of automobile gearboxes

Processing car trailer axles

Processing automobile hub axle tube

Processing automobile axle tube

Machining car arm shaft

Processing automobile axle shaft

2. Textile machinery industry:

Processing spinning machine roller

3. Mold industry:

Processing glass bottle mold

4. Motor industry:

Machining motor shaft

5. Water pump industry:

Processing water pump rotor shaft

6. Printing machinery industry:

Processing printing press cylinders and plates

Product category of mid-drive lathes:

Center Drive Lathe For Coupling、Center Drive Lathe For Supporting Roller、Center Drive Lathe For Thin-walled tube、Center Drive Lathe for glass mold、Center Drive lathe for axle .

One point of the twins spindle CNC lathe is very important. The workpiece fixture is used to correctly fix the workpiece on the spindle during the machining process. The force generated during the machining process and the fixed object must be stable and free of gaps. The fixtures with stable quality are closely related to the strong technical design and R&D capabilities. The perfect cooperation of our mechanical engineers, electrical engineers and software engineers can be regarded as a complete technical support system.

Our team engineers will be tailored to the unique needs of customers in different industries. In addition to the high efficiency of both ends simultaneous processing of the mid-drive lathe, it also greatly reduces the customer's cost input.

The CNC double-head lathe is a special machine tool, and it is an indispensable model in the manufacture of automatic production lines. The CNC twins spindle machine is integrated. The development, design and selection of machine tools, fixtures and tools, inspection and measurement, logistics transportation, protection and treatment of chips and coolant are all in one. Special-purpose machine tools are basically produced on a single machine. According to customer requirements, one design, one development, and one manufacturing are required to ensure a one-time success.

The double spindle lathe functional component industry has formed an industrial development in China, and is comparable to foreign counterparts in terms of production scale and hardware facilities. Coupled with the emergence of a number of new enterprises in recent years, these enterprises have advanced processing equipment and advanced technology concepts at home and abroad, and have always continued to research and develop, as well as continuous improvement and breakthroughs in the development of new models, pursuing perfect performance and Quality, more positive feedback in the international market, is recognized and accepted by more and more foreign customers.

Post time: Sep-18-2021