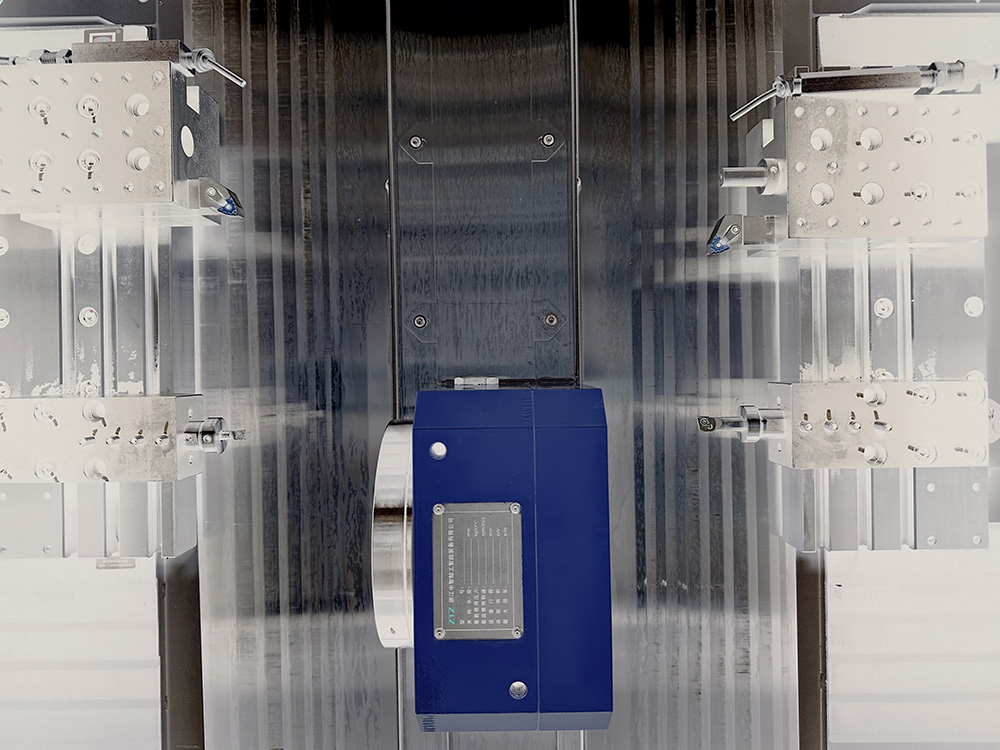

Slant Type Double-end Lathe

1.Machine features:

The central spindle is used to drive the workpiece to rotate at both ends for turning and other processing at the same time.

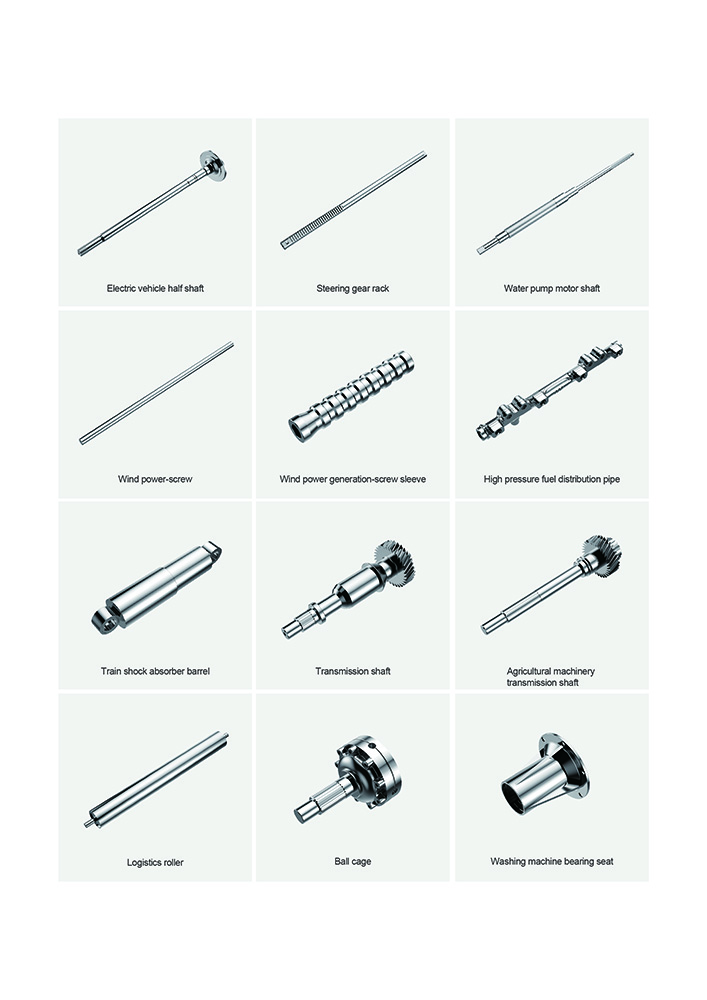

Used in new energy vehicle motor shafts, automobile transmission shafts, logistics shafts, and shock absorbers Shafts, reducer shafts, water pump motor shafts and other common industry shaft parts. Meet customers' high-eciency and high-precision processing needs.

1.1 Double processing efficiency

Compared with traditional CNC machine tools, the ZTZ double-end lathe is equipped with two sets of control systems, with a built-in central spindle, two B-axes, and two X-axes, which can realize simultaneous processing of both ends of the workpiece while rotating, increasing the efficiency by 70%-200%.

1.2.High repeatability accuracy

The roller screw guide adopts the world's first-tier brand - while achieving high speed and durability, it also ensures the accuracy of repeated positioning. The positioning accuracy can be stabilized at ≤0.008mm/300mm.

1.3.Batch processing remains stable

The inclined bracket and B-direction carriage are used to minimize the thermal deformation caused by heavy cutting and high-speed operation. It is suitable for large margin turning and ensures stable accuracy under high dynamics.

1.4.High strength and high rigidity

The HT300 one-piece cast iron lathe has an optimal support structure and a tensile strength of over 300 MPa. The one-piece cast iron structure turret has good rigidity, long tool life and a large turning tool capacity.

1.5.First-line brand core components

The core component supply chain is selected and all adopt domestic and international first-tier brands to ensure stable product quality during operation.

1.6.Four-dimensional integrated mechanical fingerprint

Each equipment product manufactured by ZTZ has an independent set of mechanical fingerprints, which includes the position accuracy, torque, vibration, and temperature rise data when leaving the factory. The four-dimensional integrated quality control system eliminates the judgment of human experience and debugs more convenient.

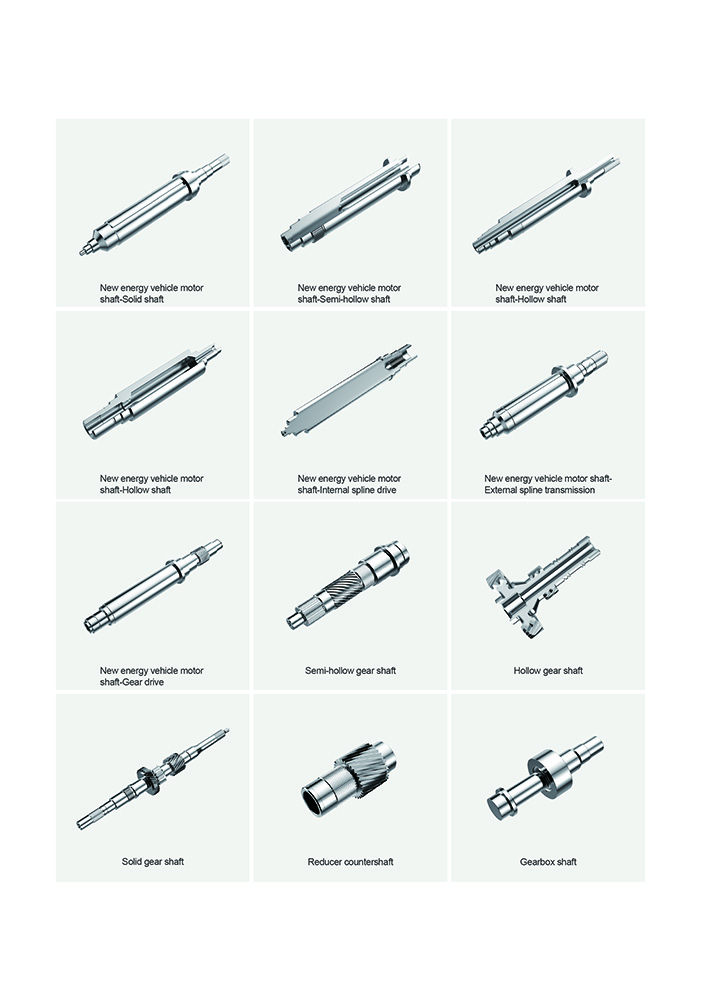

2.Main workpieces of double-end lathe series

3.Technical specications

| Name/Model |

Unit |

SC32 |

SC42 |

SC52 |

SC72 |

SC95 |

SC120 |

SC160 |

SC220 |

| Max. clamp diameter |

mm |

32 |

42 |

52 |

72 |

95 |

120 |

160 |

220 |

| Max. length |

mm |

300 |

400 |

400 |

400 |

400 |

600 |

600 |

600 |

| Min. length |

mm |

100 |

100 |

100 |

200 |

200 |

200 |

200 |

300 |

| Spindle speed |

r/min |

3500 |

3000 |

2500 |

2000 |

1600 |

1200 |

1000 |

800 |

| Spindle motor power |

Kw |

5.5 |

5.5 |

5.5 |

7.5 |

7.5 |

11 |

11 |

15 |

| Z axis speed |

m/min |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

| X axis speed |

m/min |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

| Z guide rail max travel |

mm |

400 |

400 |

400 |

400 |

400 |

400 |

400 |

400 |

| X guide rail max trave |

mm |

300 |

300 |

300 |

300 |

300 |

300 |

300 |

300 |

| Weight |

Kg |

4000 |

4000 |

4000 |

4000 |

4500 |

4500 |

4500 |

5000 |

| Size |

mm |

2800x2080x1695 |

2800x2080x1695 |

2800x2080x1695 |

2800x2080x1695 |

2800x2080x1695 |

2800x2080x1695 |

2800x2080x1900 |

3300x2080x1900 |