Six-Station Combined Machine For Butterfly Valve

Application

This machine is mainly used in processing Valve, Pump body, Auto parts, Construction machinery parts etc.It can work for many procedures,for example, End face, The outer circle, The front edge,Inner hole, Grooving, Screw thread, Bore-hole and Sphere.It worked with Huadian CNC Controller(or Siemens,Guangzhou CNC Controller), It can realize automation, high precision, multi variety and mass production.

Main features

1).Our machines all feed with Huadian CNC Controller(or Siemens, Fanuc), can achieve Biaxial linkage then finish to process Bore-hole, Screw thread and Sphere. It’s CNC Controller has good compatibility, powerful function and easy operation.

2).The Feed Sliding table guideway use high quality gray cast iron,trough rough casting, tempering and aging treatment by three times. Fully eliminate the residual internal stress, The surface of the guide way adopts super audio quenching and the hardness is up to HRC55. Through high precision guide way grinding processing, to ensure the accuracy, rigidity, stability.

3).The transmission part adopts precision ball screw and interpolation to eliminate the gap,to ensure the machine drive steady.

4).The power head is equipped with three - stage manual speed change with powerful motor,achieve low speed but high torque, can withstand heavy cutting load, improve processing efficiency.

5).The working equipment adopts Hydraulic pressure-automatic clamping, to improve efficiency and reduce labor intensity.

6).The machine adopts Centralized lubrication, to ensure that the full lubrication of each moving parts then improve the service life of machine tools.

Main structure

Our machine is mainly composed of body, power head,CNC feed sliding table,CNC cross-feed cutter, Hydraulic pressure equipment,and equipped with an independent electric cabinet, a hydraulic station, a centralized lubricating device, a cooling automatic chip remove device, and a high protection device.

1)The Body adopts integrated casting body with high quality, trough manual tempering and aging treatment by three times. The surface of the guide way is treated by super audio quenching, the structure is reasonable,to ensure rigidity, precision and the stability of the machine.

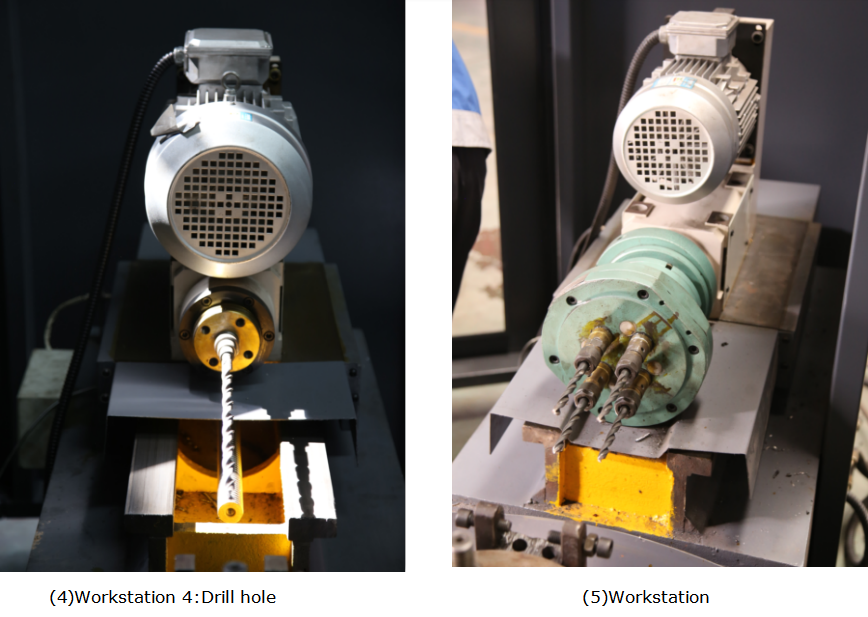

2)Description of each workstation and detailed pictures

(1)Workstation 1: Power head,Turing outer circle,Milling end face.

The body of power head is adopt excellent casting,spindle use material 20GrMnTAi,with forging, tempering, carburizing and quenching, high precision grinding out and in. The bearing adopts NN30 series high precision double row cylindrical roller bearing to ensure the rigidity and precision of the spindle.

(2)Workstation 2:Drill head and Drill hole

(3)Workstation 3: Boring hole

(6)Workstation 6:Feed station

3)Working Table

The Working Table is special designed for workpiece. The positioning block and positioning pin are quenched,to ensure the reliable positioning of workpiece. Hydraulic clamped the workpiece, to improve processing efficiency, reduce labor intensity.

4).Hydraulic device

The hydraulic station adopts the independent Superposition valve, which is composed of a high quality electromagnetic valve, a pressure regulating valve, a throttle valve and a double vane pump. And equipped with air cooling device to ensure that the hydraulic station has normal oil temperature when it works.

5)Electrical cabinet

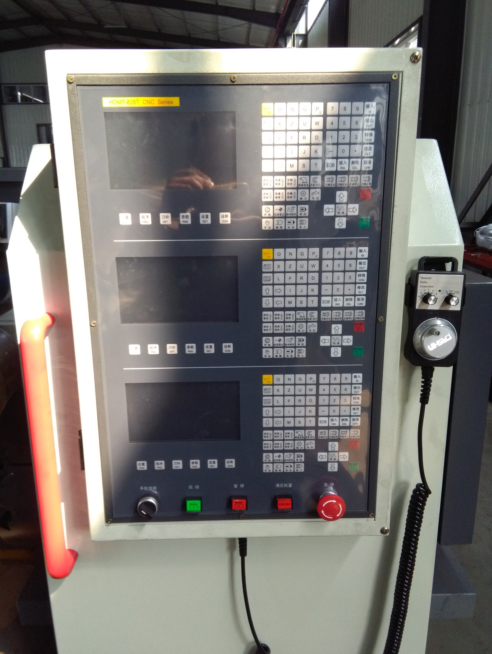

The Electrical cabinet is independent and closed.Installed with CNC controller, Inverter and electrical components.Also set air cooling device to ensure that the electrical components of the machine work properly, no dust.

6)Centralized lubrication device

The Lubrication system equipped with Nanjing Beiqier progressive lubrication device,pump the lubricating oil into the moving parts regularly. Avoid tedious manual operation, improve the service life of machine tools.

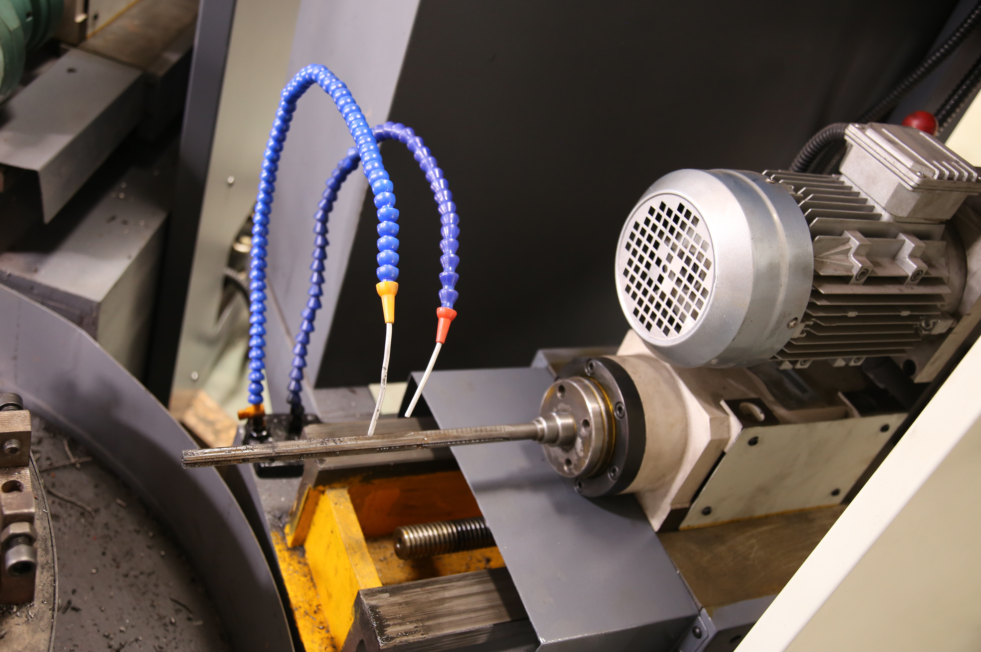

Cooling chip remove device

7)This machine adopts heavy flow cooling, The iron chips are washed by the cooling water to flow into the chip removing device through the chip removing mouth of machine body.Chips are saved into one box to ensure the cleanliness of the machine tool and reduce the labor intensity

8).Multifunction CNC Controller

This product is a high-quality CNC device with all digital bus.It keeps abreast with overseas high-grade CNC Controller,adopts upper and lower machine structure using double CPU module, modular and open architecture,based on NCUC industrial fieldbus technology with independent intellectual property rights. It has the functions of multi channel control technology, five axis machining, high speed and high precision, turning milling compound and synchronous control, using 15 'LED LCD screen. Mainly used in high speed, high precision, multi axis, multi channel vertical, horizontal machining center, turning milling compound, 5 axis gantry machine tools, etc.

Specification

|

Specification |

Unit |

HD-6ZE Parameter |

|

Total Power |

kw |

10 |

|

Equal Division Rotary Plateform |

NA |

6*60° |

|

Max.Capacity |

kg |

500 |

|

Repeat Positioning Speed |

s |

4 |

|

Dimenstion Of Plateform |

mm |

Ø660 outer |

|

Distance from plateform to spindle |

mm |

41 |

|

Spindle Tapper |

NA |

Morse No.3 |

|

Z-axis Travel |

mm |

300 |

|

Suitable Butterfly valve size |

/ |

Smaller than DN200 |

|

Accuracy |

mm |

0.01 |

|

Spindle Speed |

r/min |

260 |

|

Feeding |

mm/min |

CNC |

|

Weight |

kg |

2000 |

|

Oversal Size of Machine |

mm |

3500x3000x1600 |