Single spindle TY200 TY750 series

Product Configuration

Introduce

The 30° inclined layout and integrated bed base structure greatly improve the bending and torsional rigidity of the machine tool during operation. The high rigidity and high stability integrated bed base provide a strong guarantee for the high precision of the whole machine.

The spindle unit is an independent sleeve type. The spindle system has undergone rigorous dynamic balancing tests, with high precision, good precision retention, small thermal deformation, and good thermal stability. The Max. speed can reach 4500rpm, and the nose end runout accuracy is within 0.003MM. The front end of the shaft uses a large-diameter high-precision double-row roller bearing with a combined angular contact ball bearing structure, and the optimal span two-point balanced support design can withstand radial and axial loads. It can also be suitable for users to perform high-speed precision cutting and low-speed heavy cutting. It is especially suitable for mass production of products with complex shapes, high precision requirements, and high finish.

The high-rigidity overall design servo turret is matched with a high-precision clutch to ensure its positioning accuracy and repeat positioning accuracy. The servo motor drives the cutter head to rotate in both directions or select the tool at any nearby place. The hydraulic principle is used to loosen and clamp the clutch, and the proximity switch is used to feedback the clutch action signal to quickly and accurately achieve the tool change action.

The programmable hydraulic tailstock has a high rigidity structure and an integral tailstock, which can eliminate vibration and has excellent stability. It can be controlled by program or manual buttons, and the sleeve extension and retraction is realized by hydraulic cylinder, which is convenient, fast and reliable.

The feed system is directly driven by a servo motor, with good rigidity, precision and dynamic response characteristics. The machine tool is equipped with a roller linear guide rail, and the Max. fast moving speed can reach: 20m/min.

This machine provides users with a complete hydraulic and lubrication system, using high-quality hydraulic pumps and hydraulic valves and other components to greatly reduce the failure rate. The hydraulic and lubrication system design is simple and reliable. The machine tool adopts centralized quantitative automatic lubrication.

The Taiwan rotary chuck cylinder is used, equipped with an automatic chip removal device, which can greatly reduce the labor intensity of the operator and achieve safe and efficient production. The above functional components can all be controlled programmatically, and various special fixtures can be designed and installed according to the special requirements of users.

Technical Specifications

|

Item Model |

Name |

Unit |

200LA |

200MY |

200M |

|

Travel |

Max. bed rotation diameter |

mm |

Ф610 |

Ф660 |

Ф610 |

|

Max. processing diameter |

mm |

Ф490 |

Ф490 |

Ф450 |

|

|

Max. processing rotation diameter on tool holder |

mm |

Ф230 |

Ф280 |

Ф230 |

|

|

Max. processing length |

mm |

480 |

420 |

370 |

|

|

Distance between two centers |

mm |

550 |

550 |

550 |

|

|

Spindle Cylinder Chuck |

Spindle nose |

/ |

A2-6 |

A2-6 |

A2-6 |

|

Spindle through hole diameter |

mm |

Ф66 |

Ф66 |

Ф52 |

|

|

Max. rod through hole diameter |

mm |

Ф52 |

Ф52 |

Ф66 |

|

|

Spindle Max. speed |

rpm |

4500 |

4300 |

4300 |

|

|

Spindle motor power |

kw |

11/15 |

18/22 |

18/22 |

|

|

Spindle motor torque |

Nm |

73-165 |

91-227 |

||

|

Hydraulic cylinder/chuck |

/ |

8" |

8" |

8" |

|

|

X/Z axis feed Parameters |

X/Z motor power |

kw |

1.8 |

2.5 |

|

|

X/Z axis travel |

mm |

260/530 |

250/460 |

||

|

X/Z axis fast movement |

mm/min |

24 |

24 |

||

|

X/Z/Y motor power |

2.5/2.5//1.2 |

||||

|

X/Z/Y travel |

290/510/100(±50) |

||||

|

X/Z/Y axis fast movement |

24/24/8 |

||||

|

Slide type |

/ |

35 roller |

35roller |

35roller |

|

|

Positioning accuracy |

mm |

±0.005 |

±0.005 |

±0.005 |

|

|

Repeat positioning accuracy |

mm |

±0.003 |

±0.003 |

±0.003 |

|

|

Servo Turret parameters |

Tool station |

mm/pcs |

12T |

BMT55-12T |

BMT55-12T |

|

Power turret power/torque |

5.5/35 |

5.5/35 |

|||

|

Max. speed of power toolholder |

6000 |

6000 |

|||

|

Outer diameter tool holder specification T |

mm |

25x25 |

25x25 |

25x25 |

|

|

Inner diameter tool holder specification |

mm |

Ф40 |

Ф40 |

Ф40 |

|

|

Adjacent tool change time |

sec |

0.15 |

0.15 |

0.15 |

|

|

Tailstock parameters |

Programmable hydraulic tailstock |

/ |

Programmable hydraulics |

Programmable hydraulics |

Programmable hydraulics |

|

Tailstock Max. travel |

mm |

360 |

360 |

360 |

|

|

Sleeve diameter |

mm |

Ф100 |

Ф100 |

Ф100 |

|

|

Sleeve travel |

mm |

100 |

100 |

100 |

|

|

Sleeve taper |

/ |

MT#5 |

MT#5 |

MT#5 |

|

|

Dimensions |

Footprint approx. |

mm |

2500*2100*2000 |

2600*2100*1800 |

2500*2100*2000 |

|

Machine weight approx. |

kg |

4000 |

4200 |

4200 |

|

|

Other |

Cutting fluid tank volume |

L |

150 |

150 |

150 |

|

Hydraulic unit box volume |

L |

40 |

40 |

40 |

|

|

Hydraulic oil pump motor power |

kw |

1.5 |

1.5 |

1.5 |

|

|

Lubricating oil tank volume |

L |

2L |

2 |

2 |

|

|

Automatic lubrication pump motor power |

W |

50 |

50 |

50 |

|

|

Cooling water pump power |

W |

750 |

750 |

750 |

|

Item Model |

Name |

Unit |

750LA |

750MY |

750M |

|

Travel |

Max. bed rotation diameter |

mm |

Ф590 |

Ф690 |

Ф590 |

|

Max. processing diameter |

mm |

Ф460 |

Ф430 |

Ф350 |

|

|

Max. processing rotation diameter on tool holder |

mm |

Ф260 |

Ф300 |

Ф260 |

|

|

Max. processing length |

mm |

720 |

660 |

610 |

|

|

Distance between two centers |

mm |

780 |

780 |

780 |

|

|

spindle motor Hydro cylinder chuck |

Spindle nose |

/ |

A2-6 |

A2-6 |

A2-6 |

|

Spindle through hole diameter |

mm |

Ф66 |

Ф66 |

Ф66 |

|

|

Max. rod through hole diameter |

mm |

Ф52 |

Ф52 |

Ф52 |

|

|

Spindle Max. speed |

rpm |

4300 |

4300 |

4300 |

|

|

Spindle motor power |

kw |

18/22 |

18/22 |

18/22 |

|

|

Spindle motor power |

Nm |

91-227 |

91-227 |

91-227 |

|

|

Cylinder/chuck |

/ |

8″ |

8" |

8" |

|

|

X/Z axis feed parameter |

X/Z motor power |

kw |

1.8 |

2.5/2.5/1.2 |

2.5 |

|

X/Z axis travel |

mm |

240/770 |

268/755/±50 |

220/700 |

|

|

X/Z axis fast movement |

mm/min |

24 |

24/24/8 |

24 |

|

|

Slide type |

/ |

Roller 35 |

Roller 35 |

35滚柱 |

|

|

Servo Cutter parameters |

Tool station |

pcs |

12T |

BMT55-12T |

BMT55-12T |

|

Outer diameter tool holder specifications |

mm |

25x25 |

3.7/5.5 |

3.7/5.5 |

|

|

Inner diameter tool holder specifications |

mm |

Ф40 |

6000 |

6000 |

|

|

Adjacent tool change time |

sec |

0.15 |

25x25 |

25x25 |

|

|

Positioning accuracy |

/ |

±2" |

Ф40 |

Ф40 |

|

|

Repeat positioning accuracy |

/ |

±1" |

0.15 |

0.15 |

|

|

Tail stock parameters |

Hydraulic tailstock |

/ |

Hydraulic |

Hydraulic |

Hydraulic |

|

Tailstock Max. travel l |

mm |

650 |

Ф80 |

650 |

|

|

Sleeve diameter |

mm |

Ф80 |

80 |

Ф80 |

|

|

Sleeve travel |

mm |

80 |

650 |

100 |

|

|

Sleeve taper |

/ |

MT#5 |

MT#5 |

MT#5 |

|

|

Outline dimensions |

Footprint approx. |

mm |

2900*2100*1900 |

2900*2100*1900 |

2900*2100*1900 |

|

other |

Machine weight approx. |

kg |

4800 |

5100 |

4800 |

|

Cutting fluid tank volume |

L |

180 |

180 |

180 |

|

|

Unit box volume |

L |

40 |

40 |

40 |

|

|

Oil pump motor power |

kw |

1.5 |

1.5 |

1.5 |

|

|

Lubricating oil tank volume |

L |

2 |

2 |

2 |

|

|

Automatic lubrication pump motor power |

W |

50 |

50 |

50 |

|

|

Cooling water pump power |

W |

750 |

750 |

750 |

|

Item Model |

Name |

Unit |

200MSY |

200MS |

|

Travel |

Max. bed rotation diameter |

mm |

Ф660 |

Ф660 |

|

Max. processing diameter |

mm |

Ф370 |

Ф320 |

|

|

Max. processing diameter on tool holder |

mm |

Ф300 |

Ф300 |

|

|

Max. processing length |

mm |

380 |

400 |

|

|

Max. rod through hole diameter of main spindle/sub-spindle |

mm |

Ф46/46 |

Ф46/46 |

|

|

Spindle Cylinder Chuck |

Spindle nose |

/ |

A2-5 |

A2-5 |

|

Spindle through hole diameter |

mm |

Ф56 |

Ф56 |

|

|

Spindle Max. speed |

rpm |

5500 |

5500 |

|

|

Direct drive spindle motor power |

kw |

17.5 |

17.5 |

|

|

Direct drive spindle motor torque |

Nm |

62-125 |

62-125 |

|

|

Spindle hydraulic cylinder/chuck |

/ |

6" |

6" |

|

|

Sub-spindle Chuck |

Sub-spindle nose |

/ |

A2-5 |

A2-5 |

|

Sub-spindle through hole diameter |

mm |

Ф56 |

Ф56 |

|

|

Sub-spindle Max. speed |

rpm |

5500 |

5500 |

|

|

Direct drive spindle motor torque |

Nm |

62-125 |

17.5 |

|

|

Direct drive sub-spindle motor power |

kw |

17.5 |

62-125 |

|

|

Sub-spindle hydraulic cylinder/collet |

/ |

6" |

6" |

|

|

X/Z/Y/W axis feed Parameters |

X/Z/Y/S motor power X |

kw |

2.5/2.5/1.2/1.2 |

2.5/2.5/1.2 |

|

X/Z axis travel |

mm |

320/470 |

210/490 |

|

|

Y/S axis travel |

mm |

90(±45)/440 |

440 |

|

|

X/Z/Y/S axis fast movement |

mm/min |

24/24/8/24 |

24/24/24 |

|

|

Slide type |

mm |

Roller 35 |

35滚柱 |

|

|

Positioning accuracy |

mm |

±0.005 |

±0.005 |

|

|

Repeat positioning accuracy |

mm |

±0.003 |

±0.003 |

|

|

Servo power Turret parameters |

Power turret type |

/ |

BMT55-12T |

BMT55-12T |

|

Power turret power/torque |

Kw |

5.5/35 |

5.5/35 |

|

|

Power tool holder Max. speed |

rpm |

6000 |

6000 |

|

|

Outer diameter tool holder specifications |

mm |

25*25 |

25*25 |

|

|

Inner diameter tool holder specifications |

mm |

Ф40 |

Ф40 |

|

|

Adjacent tool change time |

sec |

0.2 |

0.2 |

|

|

Dimensions

|

Occupied area Approx. |

mm |

2600*2100*1900 |

2600*2100*1900 |

|

Machine weight Approx. |

kg |

4200 |

4200 |

|

|

Other |

Cutting fluid tank volume |

L |

150 |

150 |

|

Hydraulic unit box volume |

L |

40 |

40 |

|

|

Hydraulic oil pump motor power |

kw |

1.5 |

1.5 |

|

|

Lubricating oil tank volume |

L |

2 |

2 |

|

|

Automatic lubrication pump motor power |

W |

50 |

50 |

|

|

Cooling water pump power |

W |

750 |

750 |

Configuration Introduction

Easier To Use And More Powerful

●Fully upgraded design

●Equipped with i HMI

●Equipped with FANUC's latest CNC and servo technology

●Standardized with personalized functions

●Expanded memory capacity

Ease Of Use

Prevent sudden machine downtime through preventive maintenance

●Rich fault prediction functions

Easily locate the fault location and shorten recovery time

●Diagnosis/maintenance functions

High processing performance

Shortened Cycle Time

●High-efficiency processing technology

Achieve high-quality processing

Surface fine processing technology

●Diagnosis/maintenance function

High Operation Rate

Always support various operations at the processing site

●FANUC

Personalized Screen Is Easier To Use

●Standardized personalized function

Initiatives in the field of IoT

●Support for a wide range of on-site networks

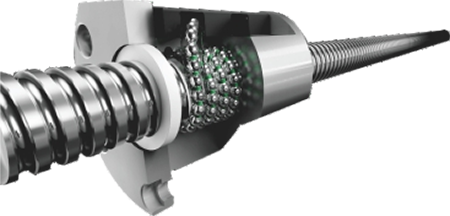

THK Ball Screw

·C3 grade, using high-precision ball screw, with nut pre-loading and screw pre-tensioning treatment to pre-eliminate backlash and temperature rise elongation, showing excellent positioning and repeatability accuracy.

·Servo motor direct drive to reduce backlash error.

THK Roller Linear Guide

·P grade ultra-high rigidity SRG precision grade, linear guide zero clearance, arc cutting, bevel cutting, surface texture is relatively uniform. Suitable for high-speed operation, greatly reducing the driving horsepower required for machine tools.

·Rolling instead of sliding, small friction loss, sensitive response, high positioning accuracy. It can bear the load in the moving direction at the same time, and the track contact surface is still in multi-point contact during the load, and the cutting rigidity will not be reduced.

·Easy to assemble, strong interchangeability, and simple lubrication structure; the wear amount is very small and the service life is long.

SKF Bearing/Oiling Machine

·Automatic lubricator meets the needs of various applications, suitable for various working conditions, reliable products, flexible use.

·Meet the needs of bearing lubrication in high temperature, strong vibration and dangerous environment.

Each lubrication point uses a volumetric proportional distributor to control the lubrication amount, and the machine can be controlled by PLC to accurately supply oil.