Servo Turret Tailstock T Series

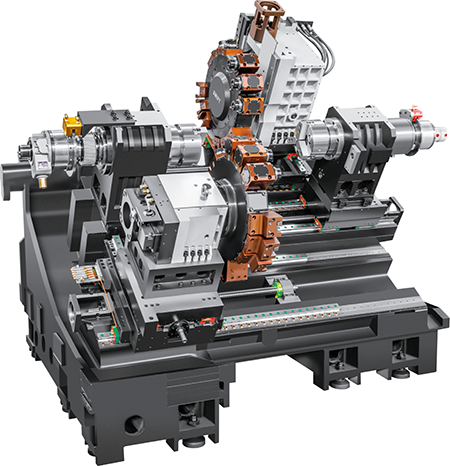

Product Configuration

Machine features

High rigidity, heavy cutting, and high stability: It adopts an integral cast incLined bed, a 30° incLined bed structure, and a thick rib design to minimize distortion and thermal deformation.

High precision and high dynamic response: High precision ball bearings are used at the front and rear to achieve high spindle rigidity and extremely high spindle rotation accuracy.

Spindle servo unit, high precision and convenient maintenance.

High efficiency: The maximum spindle speed is 4500rpm/min, and the rapid movement can reach 30m/min.

Technical Specifications

|

Project |

CNC-460T(460) |

CNC-520T(460) |

CNC-520T(520) |

CNC-650T(700) |

|

|

Bed Frame |

The bed and base are made of high-quality cast iron, and the bed is 40° inclined. |

The bed and base are made of high-quality cast iron, and the bed is slanted at 30°. |

|||

|

Processing |

Max. swing diameter over bed |

580mm |

580mm |

600mm |

600mm |

| Max. processing diameter of discs |

400mm |

400mm |

350mm |

400mm |

|

| Max. processing diameter of the carriage |

280mm |

280mm |

350mm |

400mm |

|

| Max. processing length of bar |

460mm |

460mm |

520mm |

700mm |

|

| Max. bar diameter |

ф45mm |

ф51mm |

ф51mm |

ф65mm |

|

|

Travel |

Max.X-axis travel |

230mm |

240mm |

220mm |

220mm |

| Max. Z-axis travel |

500mm |

500mm |

550mm |

770mm |

|

| X/Z-axis rapid speed |

30mmin |

30m/min |

24m/min |

25m/min |

|

| X/Z screw diameter/pitch |

32/10mm |

32/10mm |

X:40/10mm |

40/10mm |

|

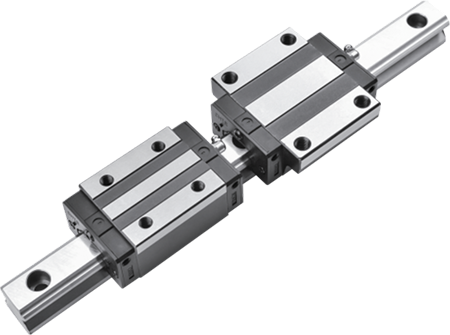

| X/Z linear guide width |

35mm |

35mm |

45mm |

35mm |

|

| X-axis servo motor |

β12(Brake) |

β12(Brake) |

β12(Brake) |

β12(Brake) |

|

| Z-axis servo motor |

β12 |

β12 |

β12 |

β12 |

|

| Turret servo motor |

3N.m |

3N.m |

3N.m |

3N.m |

|

|

Accuracy |

X/Z-axis positioning accuracy |

±0.003mm |

±0.003mm |

±0.003mm |

±0.003mm |

| X/Z-axis repeatability |

±0.003mm |

±0.003mm |

±0.003mm |

±0.003mm |

|

|

Moving Tailstock |

Tailstock sleeve specifications |

Mohs#5 |

Mohs#5 |

Mohs#5/80 |

Mohs#5 |

| Tailstock sleeve travel |

40-460mm |

40-460mm |

50-600mm |

50-800mm |

|

| Tailstock pressure range |

5-30Kg/cm² |

5-30Kg/cm² |

5-30Kg/cm² |

5-30Kg/cm² |

|

| Tailstock moving method |

Programmable hydraulic |

Programmable hydraulic |

Programmable hydraulic |

Saddle driven, |

|

|

Spindle |

Spindle taper |

A2-5 |

A2-6 |

A2-6 |

A2-6 |

| Spindle bore diameter |

ф56mm |

ф75mm |

ф75mm |

ф75mm |

|

| Max. spindle speed |

6000rpm |

4500rpm |

4500rpm |

4000rpm |

|

| Spindle servo motor power |

7.5/11KW |

1KW |

11/15KW |

11/15KW |

|

| Chuck / rotary cylinder |

6"/6" |

8"/8" |

8"/8时 |

8" |

|

|

Turret |

Turret specifications |

80Center high/ |

80Center high/ |

100Center high/ |

100Center high/ |

| Large cutterhead |

340 |

340 |

420 |

380 |

|

| Tool holder specifications |

□25×25 |

□25×25 |

□25×25 |

□25×25 |

|

| Boring tool holder |

ф40mm |

ф40mm |

ф40mm |

ф40mm |

|

|

Other |

Total capacitance |

15KW |

20KW |

20KW |

20KW |

| Machine tool net weight |

About 4500Kg |

About 4500K |

About 5000Kg |

About 5700Kg |

|

| Machine size (length × width × height) |

2600×1700×1900mm |

2600×1700×1900mm |

2800×2000×1900mm |

2800×1800×1800mm |

|

|

Project |

CNC-860T(1000) |

CNC-860T(2000) |

CNC-860T(3000) |

|

|

Bed Frame |

The bed and base are made of high-quality cast iron, and the bed is slanted at 40°. |

|||

|

Processing |

Max. swing diameter over bed |

780mm |

7800m |

780mm |

| Max. processing diameter of discs |

600mm |

600mm |

600mm |

|

| Max. processing diameter of the carriage |

500mmmm |

500mmm |

500mmm |

|

| Max. processing length of bar |

1000mm |

2000mm |

3000mm |

|

| Max. bar diameter |

ф75mm |

ф75mm |

ф75mm |

|

|

Travel |

Max.X-axis travel |

350mm |

350mm |

350mm |

| Max. Z-axis travel |

1050mm |

2050mm |

3050mm |

|

| X/Z-axis rapid speed |

18m/min |

18m/min |

15m/min |

|

| X/Z screw diameter/pitch |

X50/08mm |

X:50/08mm |

X:50/08mm |

|

| X/Z linear guide width |

55mm |

55mm |

55mm |

|

| X-axis servo motor |

P22(Brake) |

β22(Brake) |

β22(Brake) |

|

| Z-axis servo motor |

β22 |

β22 |

β30 |

|

| Turret servo motor |

3N.m |

3N.m |

3N.m |

|

|

Accuracy |

X/Z-axis positioning accuracy |

±0.003/300mm |

±0.003/300mm |

±0.003/300mm |

| X/Z-axis repeatability |

±0.003/300mm |

±0.003/300mm |

±0.003/300mm |

|

|

Moving Tailstock |

Tailstock sleeve specifications |

Mohs#5 |

Mohs#5 |

Mohs#5 |

| Tailstock sleeve travel |

ф150/200mm |

ф150/200mm |

ф150/200 |

|

| Tailstock pressure range |

5-30Kg/cm² |

5-30Kg/cm² |

5-30Kg/cm |

|

| Tailstock moving method |

Programmable hydraulic |

Programmable hydraulic |

Programmable hydraulic |

|

|

Spindle |

Spindle taper |

A2-8 |

A2-8 |

A2-8 |

| Spindle bore diameter |

ф88mm |

ф8Bmm |

ф88mm |

|

| Max. spindle speed |

2500rpm |

2500rpm |

2500rpm |

|

| Spindle servo motor power |

15KW |

18.5KW |

22KW |

|

| Chuck / rotary cylinder |

10"/10" |

10"/10" |

10"/10" |

|

|

Turret |

Turret specifications |

100Center high/ |

125Center high/ |

125Center high/ |

| Large cutterhead |

440 |

440 |

440 |

|

| Tool holder specifications |

□32×32 |

□32×32 |

□32×32 |

|

| Boring tool holder |

ф50mm |

ф50mm |

ф50mm |

|

|

Other |

Total capacitance |

27KW |

31KW |

35KW |

| Machine tool net weight |

About 7700Kg |

About 9700Kg |

About 18500Kg |

|

| Machine size (length × width × height) |

6000×2300x2550mm |

7000×2300×2550mm |

7500×2500×2550mm |

|

|

Project |

CNC-960T(1000) |

CNC-960T(2000) |

CNC-960T(3000) |

|

|

Bed Frame |

The bed and base are made of high-quality cast iron, and the bed is slanted at 40°. |

|||

|

Processing |

Max. swing diameter over bed |

880mm |

880mm |

880mm |

| Max. processing diameter of discs |

600mm |

600mm |

600mm |

|

| Max. processing diameter of the carriage |

600mmm |

600mmm |

600mmm |

|

| Max. processing length of bar |

1000mm |

2000mm |

3000mm |

|

| Max. bar diameter |

ф91mm |

φ91mm |

φ91mm |

|

|

Travel |

Max.X-axis travel |

350mm |

350mm |

350mm |

| Max. Z-axis travel |

1050mm |

2050mm |

3050mm |

|

| X/Z-axis rapid speed |

18m/min |

18m/min |

15m/min |

|

| X/Z screw diameter/pitch |

X:50/08mm |

X:50/08mm |

X:50/08mm |

|

| X/Z linear guide width |

55mm |

55mm |

55mm |

|

| X-axis servo motor |

β22(Brake) |

β22(Brake) |

β22(Brake) |

|

| Z-axis servo motor |

β22 |

β22 |

β30 |

|

| Turret servo motor |

3N.m |

3N.m |

3Nm |

|

|

Accuracy |

X/Z-axis positioning accuracy |

±0.003/300mm |

±0.003/300mm |

±0.003/300mm |

| X/Z-axis repeatability |

±0.003/300mm |

±0.003/300mm |

±0.003/300mm |

|

|

Moving Tailstock |

Tailstock sleeve specifications |

Mohs#5 |

Mohs#5 |

Mohs#5 |

| Tailstock sleeve travel |

ф150/200mm |

ф150/200mm |

ф150/200mm |

|

| Tailstock pressure range |

5-30Kg/cm² |

5-30Kg/cm² |

5-30Kg/cm² |

|

| Tailstock moving method |

Programmable hydraulic |

Programmable hydraulic |

Programmable hydraulic |

|

|

Spindle |

Spindle taper |

A2-11 |

A2-11 |

A2-11 |

| Spindle bore diameter |

ф105mm |

ф105mm |

ф105mm |

|

| Max. spindle speed |

2200rpm |

2200rpm |

2200rpm |

|

| Spindle servo motor power |

15KW |

22KW |

22KW |

|

| Chuck / rotary cylinder |

12"/12" |

12"/12" |

12"/12" |

|

|

Turret |

Turret specifications |

125Center high/ |

125Center high/ |

125Center high/ |

| Large cutterhead |

440 |

440 |

440 |

|

| Tool holder specifications |

□32×32 |

□32×32 |

□32×32 |

|

| Boring tool holder |

ф50mm |

ф50mm |

ф50mm |

|

|

Other |

Total capacitance |

27KW |

35KW |

35KW |

| Machine tool net weight |

About 8200Kg |

About 10200Kg |

About 12700Kg |

|

| Machine size (length × width × height) |

6000×2300x2550mm |

7000×2300×2550mm |

8500×2300×2550mm |

|

Configuration Features

Spindle

Support high-precision and heavy-duty cutting to increase productivity.

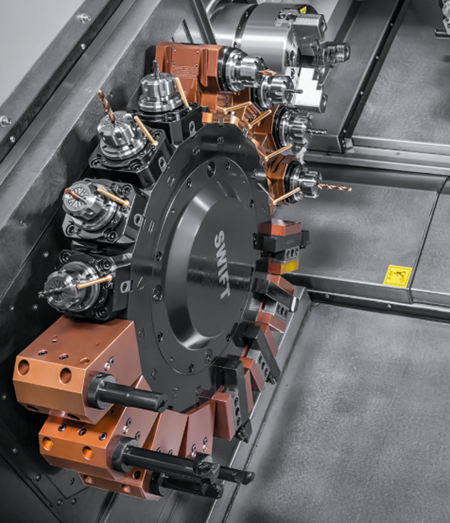

Turret

Improves indexing reliability and ensures high rigidity.

System

Standard FANUC F Oi-TF Plus CNC System, high processing performance high operating rate, high ease of use.

High Rigidity

Heavy-duty Cast Iron Base And Components, Strong shock absorption and high stability.

Ball Screw

Screw pretensioning, backlash andtemperature rise elongation areeliminated in advance.

Roller Linear Guide

Arc cutting, bevel cutting, and uniform surface texture. Universal high-speed rotation.