Renewable Design for Cnc Gantry Milling Machine - Center Drive Lathe For Axle – Oturn

Renewable Design for Cnc Gantry Milling Machine - Center Drive Lathe For Axle – Oturn Detail:

Automobile axle technology analysis

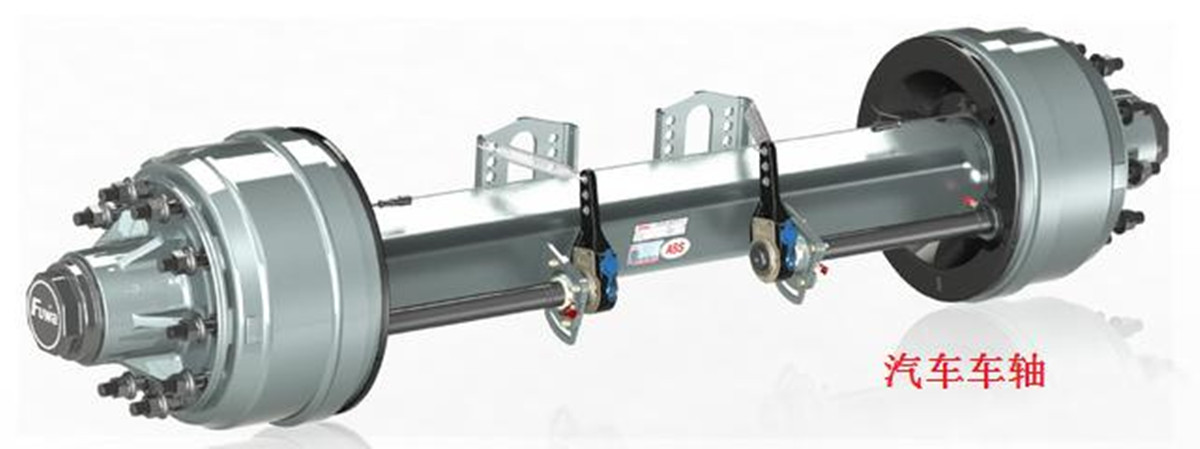

Automobile axle

The axles with wheels on both sides of the undercarriage (frame) are collectively referred to as automobile axles, and the axles with driving capabilities are generally called axles. The main difference between the two is whether there is a drive in the middle of the axle (axle). In this paper, the automobile axle with the drive unit is called the automobile axle, and the vehicle without the drive is called the automobile axle to show the difference.

With the increasing demand for logistics and transportation, the superiority of automobile axles, especially trailers and semi-trailers, in professional transportation and special operations is becoming more and more obvious, and the market demand has increased significantly.

This technology analysis the machining process of the axle, hope to help customers to choose more suitable CNC machine.

Automobile axle classification:

The types of axles are different according to the brake type, and are divided into: disc brake axles, drum brake axles, etc.

According to the size of the shaft diameter structure, it is divided into: American axle, German axle; etc.

According to the shape and structure, it is divided into:

the whole: solid square tube axle, hollow square tube axle, hollow round axle;

split body: shaft head + hollow shaft tube welding.

From the processing content of the axle, the solid and hollow axles are related to the selection of processing equipment.

The following are the analysis of the production process of the whole axle (also divided into solid and hollow; square tube and round tube), and split axle (solid and hollow shaft head + hollow shaft tube welding), In particular, the machining process is analyzed to better select the more suitable machine.

Production process and machine for automobile axles:

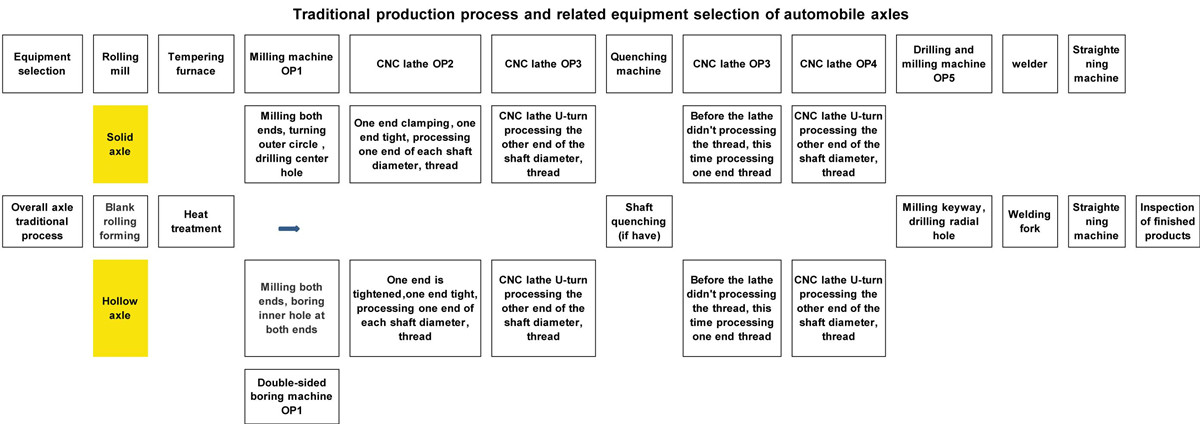

1. The traditional production process of the overall axle:

From the above axle production process, at least three types of machine tools are needed to complete the machining: milling machine or double-sided boring machine, CNC lathe, drilling and milling machine, and CNC lathe needs to be turned around (some customers have chosen double-head CNC lathe). Regarding thread processing, if the shaft diameter is quenched, it is processed after quenching; if there is no quenching, it is processed in OP2 and OP3, and the OP4 and OP5 sequence machine tools are omitted.

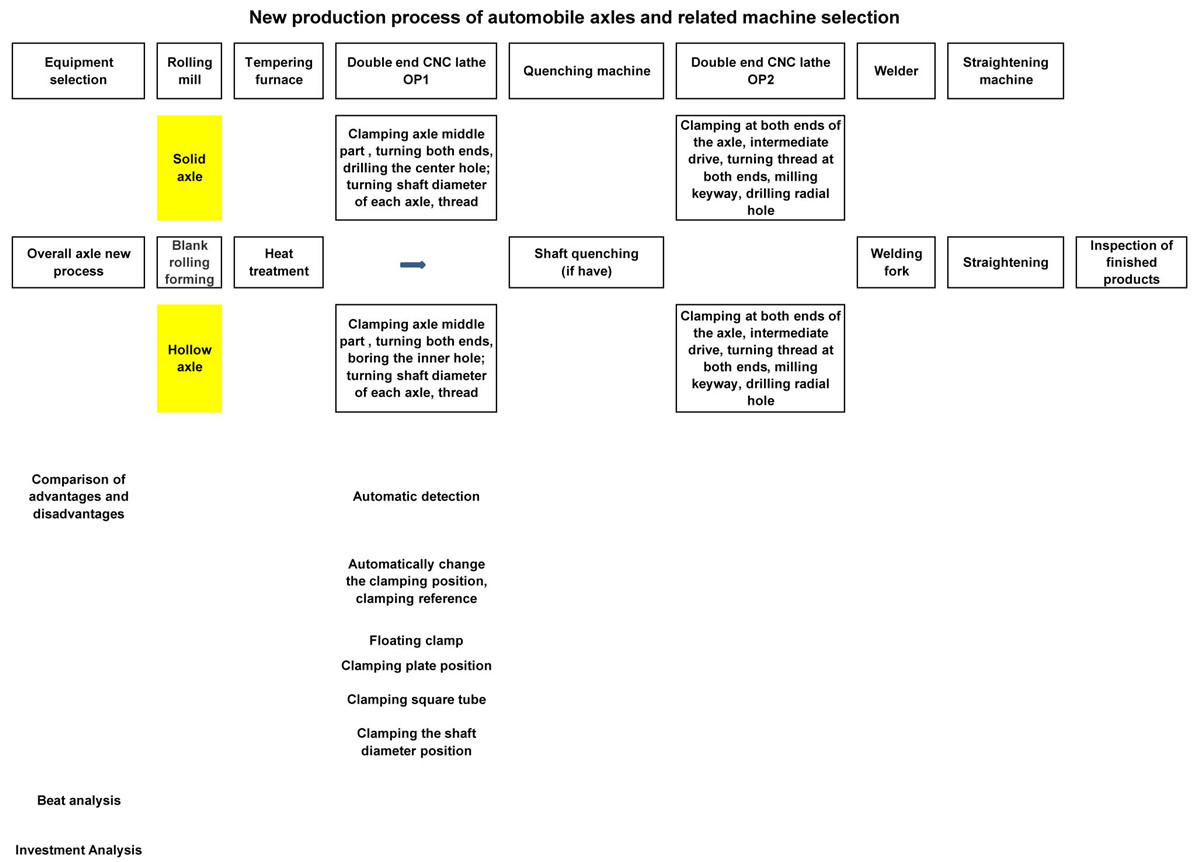

From the new production process, the milling machine used for machining (solid axle) or double-sided boring machine (hollow axle) plus CNC lathe, traditional OP1 milling, OP2, OP3 turning sequence, and even OP5 drilling and milling It can be replaced by the double-end CNC lathe OP1.

For solid axles where the shaft diameter does not require quenching, all the machining contents can be completed in one setup, including milling key grooves and drilling radial holes. For hollow axles where the shaft diameter does not require quenching, the automatic conversion clamping standard can be realized in the machine tool, and the machining content can be completed by one machine tool.

Choose double-end axle special CNC lathes to machine the axles significantly shortens the machining route, and the type and quantity of selected machine tools will also be reduced.

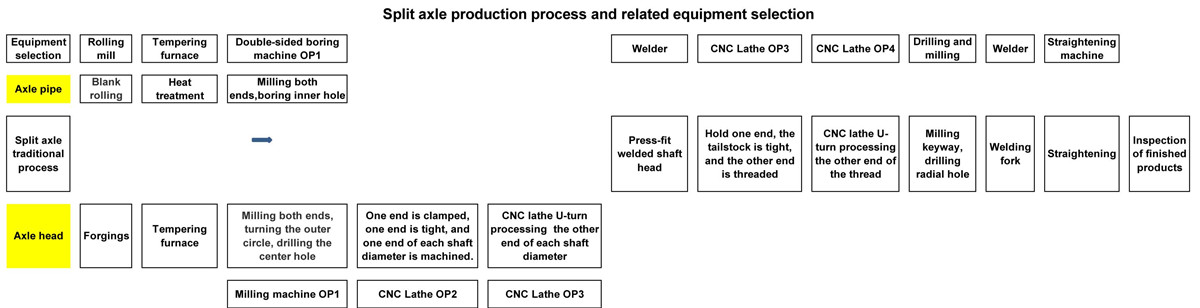

3.Split axle production process:

From the above process, the processing equipment of the axle tube before welding can also be selected as a double-end CNC lathe. For the processing of the axle after welding, the special CNC lathe for double-end axles should be the first choice: simultaneous processing at both ends, high processing efficiency and good machining accuracy. If the keyway and radial hole at both ends of the axle need to be machined, the machine can also be equipped with a power tool holder to process the subsequent keyway and radial hole together.

4.The advantage and feature of the new process selection machine:

1) Concentration of the process, reducing the times of workpiece clamping, reducing the auxiliary processing time, using the simultaneous processing technology at both ends, the production efficiency is significantly improved.

2) One-time clamping, simultaneous processing at both ends improves the machining accuracy and coaxiality of the axle.

3) Shorten the production process, reduce the turnover of parts on the production site, improve the efficiency of the use of the site, and help improve the organization and management of production.

4) Due to the use of high-efficiency processing equipment, it can be equipped with loading and unloading devices and storage devices to achieve fully automated production and reduce labor costs.

5) The workpiece is clamped at the intermediate position, the clamping is reliable, and the torque required for the cutting of the machine tool is sufficient, and the large amount of turning can be performed.

6) The machine tool can be equipped with automatic detection device, especially for the hollow axle, which can ensure the uniform thickness of the axle after machining.

7) For hollow axles, when the inner holes at both ends of the OP1 sequencer are finished, the traditional customer will use one end to raise the clamp and the other end to use the tailstock to tighten the workpiece for turning, but the size of the inner hole is different. For the smaller inner hole, the tightening rigidity is insufficient, the top tightening torque is insufficient, and efficient cutting cannot be completed.。

For the new double-face lathe, the hollow axle, when the inner holes at both ends of the vehicle are finished, the machine automatically switches the clamping mode: the two ends are used to tighten the workpiece, and the middle drive floats the workpiece to transmit torque.

8) The headstock with built-in hydraulic clamping workpiece can be moved in the Z direction of the machine. The customer can hold the position in the middle square tube (round tube), the bottom plate position and the shaft diameter position of the axle as needed.

5.Conclusion:

In view of the above situation, the use of double-end CNC lathes to machine automobile axles has significant advantages over traditional processes. It is an advanced manufacturing technology that can replace traditional machine tools in terms of production process and machine structure.

The middle section of

6.Axle customer case

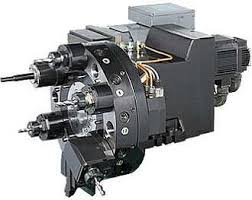

Special Double-end Axle CNC lathe Introduction

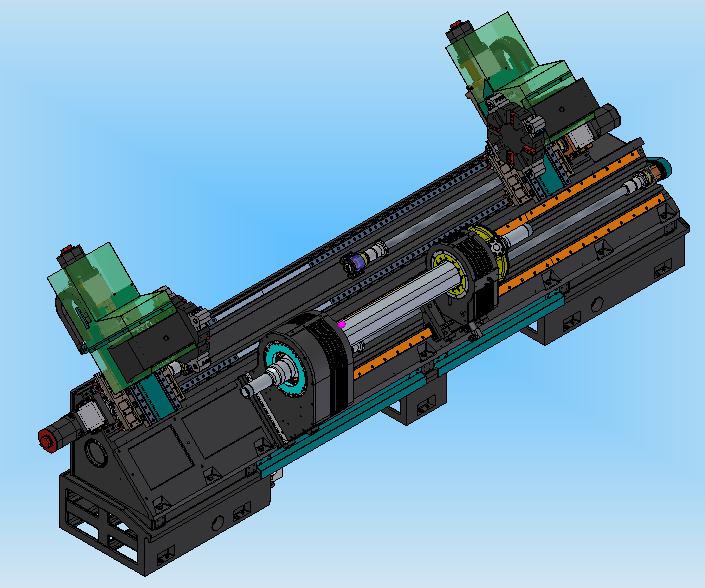

Axle processing range: ∮50-200mm, □50-150mm, processing length: 1000-2800mm

Machine structure and performance introduction

The machine tool adopts a 45°slant bed layout, which has good rigidity and easy chip evacuation. The headstock with intermediate drive clamping function is arranged in the middle of the bed, and the two tool holders are arranged on both sides of the spindle box. The minimum clamping length of the machine is 1200mm and the maximum machining length is 2800mm. The rolling guide is adopted, and each servo feed shaft adopts a high-mute ball screw, and the elastic coupling is directly connected, and the noise is low, the positioning accuracy and the repeated positioning precision are high.

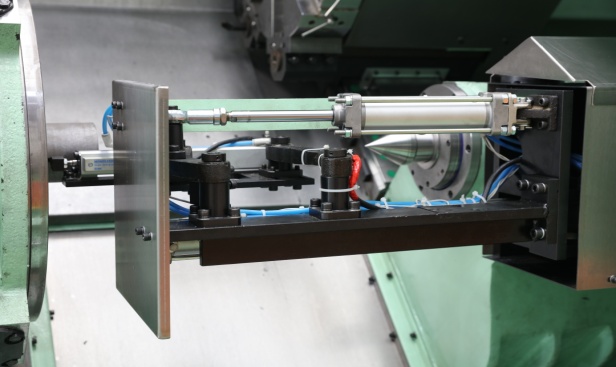

■The machine is equipped with a two-channel control system. The two tool holders can be linked to the spindle at the same time or separately to complete simultaneous or sequential machining of the two ends of the part.

■The machine is equipped with a double headstocks. The main headstock is fixed in the middle of the bed, and the servo motor supplies power to the main shaft through the toothed belt. The sub-spindle box is installed on the lower guide rail of the machine tool, coaxial with the main spindle box, and can be moved axially by the servo motor to facilitate the loading and unloading of parts, and it is convenient to adjust different clamping positions. When machining parts, the sub-spindle base is locked to the machine rail. The coaxial accuracy of the two headstocks is guaranteed by the manufacturing process, resulting in a higher degree of concentricity of the machined parts.

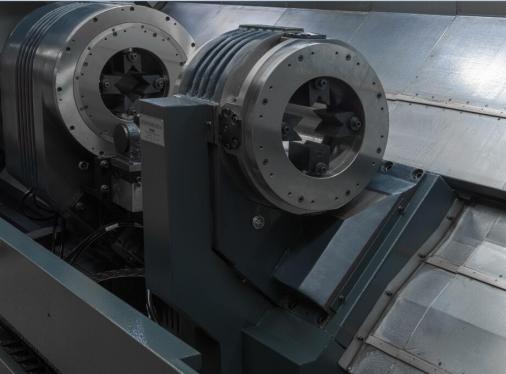

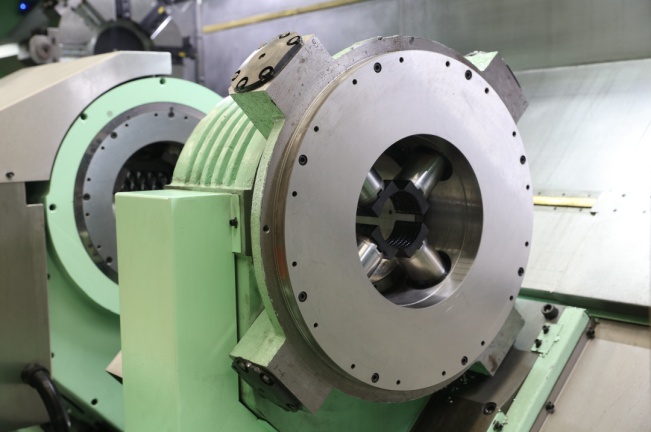

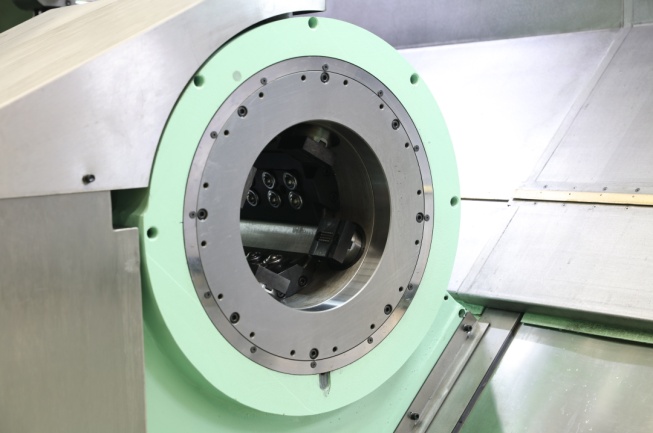

■The Headstock integrates the spindle system, the fixture and the oil distribution system, and has a compact structure and reliable operation. The specific clamping diameter and the width of the headstock are determined by the customer’s axle parts.

The main headstock is slowed down by two stages of belt and gear, enabling the spindle to output a large torque. A clamp is installed on the left end of the main headstock and the right end of the sub-headstock respectively to realize the clamping of the parts. When the main headstock drives the parts to rotate, the sub-headstock clamp clamping parts rotate with the main headstock.

The fixture is equipped with three radial cylinders (four radial cylinders if both the round material and the square material are clamped), the piston is reciprocated by the hydraulic pressure, and the claws are installed at the end of the piston to realize the self-centering of the parts. Clamping. It is quick and easy to change the claws when changing the parts. The clamping force is adjusted by the hydraulic system hydraulic pressure. When the part is machined, the clamp rotates with the main shaft, and the oil distribution system supplies oil to the clamp, so that the clamp has sufficient clamping force during rotation. The clamp has the advantages of large clamping force and large claw stroke.

■In order to solve the problem of uniform wall thickness after the customer’s hollow axle machining, the machine can be equipped with automatic workpiece inspection device. After the axle clamping is completed, the workpiece automatically detects that the probe extends and measures the position of the workpiece; after the measurement is completed, the device retracts into the closed space.

For different machining processes of hollow axles, if the bearing position is used as the clamping reference, the machine structure with automatic clamping and clamping can be selected, and the programmable tailstock is provided on both sides of the main and auxiliary spindle heads to meet the requirements of one machine. It is expected to complete the processing of two steps at a time. At the same time, it also makes the parts of the automatic loading and unloading have more and better choices.

■The left and right tool holders can be equipped with ordinary rotary tool holders or power turrets. They have drilling and milling functions, which can complete drilling and milling of key parts.

■The machine tool is fully enclosed and equipped with automatic lubrication device and automatic chip removal device (front). It has good protection performance, beautiful appearance, easy operation and convenient maintenance.

■The detail machine specifications and configurations are determined according to the axle requirements and customer requirements, and will not be repeated here.

Thanks for your attention!

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.