Professional China Deep Hole Drilling Machine - CNC Vertical Machining Center – Oturn

Professional China Deep Hole Drilling Machine - CNC Vertical Machining Center – Oturn Detail:

Machine Features

OTURN machining center is made of the best high-quality Mihanna cast iron body and full rib support, which is ten times more shock-absorbing than ordinary steel wire. The castings with ribs on the inside of the fuselage have extremely high torsion resistance and super shock resistance. In addition, the wide internal space allows the operator to easily change tools and work items. With the high rigidity structure, it creates a small footprint, but high-precision and multi-bacterial automatic machinery.

Ou Teng uses well-known brands of high rigidity and precision linear slide rails. Its process technology is like manufacturing bearings, with zero clearance and all-round bearing characteristics. The linear slide has low consumption, high precision, and fast moving speed, up to 48 meters per minute.

The machine is equipped with high-brightness work lights, which is convenient for the operator to load and unload workpieces and make measurements. The work light has the functions of dustproof, waterproof and explosion-proof.

A fast, simple, reliable and long-life tool exchange device provides smooth and reliable tool exchange. The unique tool exchange device design, the ability to select tools at any position, can be quickly reached by PLC software control.

Specification

|

Item |

Unit |

V850 |

V1160 |

V1370 |

V1580 |

|

Machining range |

|||||

|

X axis travel |

mm |

800 |

1100 |

1300 |

1500 |

|

Y axis travel |

mm |

550 |

600 |

700 |

800 |

|

Z axis travel |

mm |

550 |

600 |

700 |

700 |

|

Distance from the nose of the spindle to the worktable |

mm |

120-670 |

120-720 |

120-820 |

|

|

Distance from the center of the spindle to the track surface of the column |

mm |

595 |

650 |

750 |

865 |

|

Worktable |

|||||

|

Table size |

mm |

1000×550 |

1200×600 |

1400×700 |

1600×800 |

|

Maximum load of workbench |

kg |

500 |

800 |

||

|

T-slot |

mm |

5x18x90 |

5x18x100 |

7x22x110 |

7x22x100 |

|

Spindle |

|||||

|

Spindle speed |

rpm |

8000 |

6000 |

||

|

Spindle torque |

N.m |

35/47.7 |

47/70 |

140/190 |

|

|

Spindle taper |

BT-40 |

BT-50 |

|||

|

Spindle power |

KW |

7.5 |

11 |

15 |

|

|

Other |

|||||

|

Dimensions |

mm |

2600x2500x2700 |

3200x2700x3000 |

4180x3050x3187 |

4580x3050x3187 |

|

Machine weight |

T |

5 |

6.5 |

10 |

15.5 |

Detail Configuration

Double spiral chip removal

Double spiral chip removal device, punched to the spiral chip removal machine on both sides of the machine, can easily send the processed iron chips to the outside of the machine quickly, reducing the waste of non-processing time due to the removal of iron chips.

All machines use laser measurement, cutting test, long-term running-in test and strict inspection according to VDI 3441 standard, so that each axis has good repeatability and accurate positioning, ensuring machine accuracy.

The circular measuring instrument Renishaw is used to correct the roundness and the geometric accuracy of the machine, thereby checking and ensuring the vertical accuracy of the three-dimensional space.

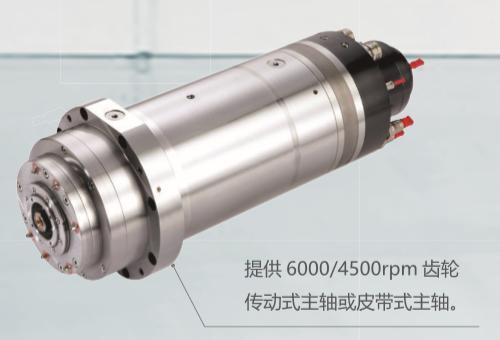

The sleeve-type spindle design provides 6000/4500rpm gear-driven spindle or belt-type spindle, and the short-nosed spindle bearing is effectively supported by the sleeve and head casting, so it can greatly improve the rigidity of the spindle. The spindle motor can display the maximum metal cutting rate. With the spindle cooling system, the temperature rise of the bearing can be reduced to extend the life of the spindle.

Workpiece

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.