OEM/ODM Factory Cnc High Speed Flange Drilling Machine - CNC Horizontal Machining Center – Oturn

OEM/ODM Factory Cnc High Speed Flange Drilling Machine - CNC Horizontal Machining Center – Oturn Detail:

Machine Features

H series horizontal machining center adopts internationally advanced T-shaped overall bed structure, gantry column, hanging box structure, strong rigidity, good accuracy retention, suitable for precision cabinets.

For the processing of parts, multi-face milling, drilling, reaming, boring, tapping, etc. can be performed in one clamping at one time, machine are widely used in automobiles, rail transit, aerospace, valves, mining machinery, textile machinery, plastic machinery, ships, electric power and other fields..

Specification

|

Item |

Unit |

H63 |

H80 |

||

|

Worktable |

Workbench size (length×width) |

mm |

630×700 |

800×800 |

|

|

Workbench indexing |

° |

1°×360 |

|||

|

Countertop form |

24×M16 Threaded hole |

||||

|

Maximum load of worktable |

kg |

950 |

1500 |

||

|

Maximum turning diameter of worktable |

mm |

Φ1100 |

Φ1600 |

||

|

Travel |

Move the table left and right (X axis) |

mm |

1050 |

1300 |

|

|

Headstock moves up and down (Y axis) |

mm |

750 |

1000 |

||

|

Column moves forward and backward (Z axis) |

mm |

900 |

1000 |

||

|

Distance from spindle center line to table surface |

mm |

120-870 |

120-1120 |

||

|

Distance from spindle end to center of worktable |

mm |

130-1030 |

200-1200 |

||

|

Spindle |

Spindle taper hole number |

IS050 7:24 |

|||

|

Spindle speed |

rpm |

6000 |

|||

|

Spindle motor power |

Kw |

15/18.5 |

|||

|

Spindle output torque |

Nm |

144/236 |

|||

|

|

Tool holder standard and model |

MAS403/BT50 |

|||

|

Feeding |

Fast moving speed (X, Y, Z) |

m/min |

24 |

||

|

Cutting feed rate (X, Y, Z) |

mm/min |

1-20000 |

1-10000 |

||

|

Feed motor power (X, Y, Z, B) |

kW |

4.0/7.0/7.0/1.6 |

7.0/7.0/7.0 |

||

|

Feed motor output torque |

Nm |

X、Z:22;Y:30;B8 |

30 |

||

|

ATC |

Tool magazine capacity |

PCS |

24 |

24 |

|

|

Tool change method |

Arm type |

||||

|

Max. Tool size |

Full tool |

mm |

F110×300 |

||

|

Adjacent without tool |

F200×300 |

||||

|

Tool weight |

kg |

18 |

|||

|

Tool change time |

S |

4.75 |

|||

|

Others |

Air pressure |

kgf/cm2 |

4~6 |

||

|

Hydraulic system pressure |

kgf/cm2 |

65 |

|||

|

Lubricant tank capacity |

L |

1.8 |

|||

|

Hydraulic oil tank capacity |

L |

60 |

|||

|

Cooling box capacity |

L |

Standard:160 |

|||

|

Cooling pump flow/head |

l/min,m |

Standard : 20L/min,13m |

|||

|

Total electrical capacity |

kVA |

40 |

65 |

||

|

Machine weight |

kg |

12000 |

14000 |

||

|

|

CNC system |

Mistubishi M80B |

|||

Main Configuration

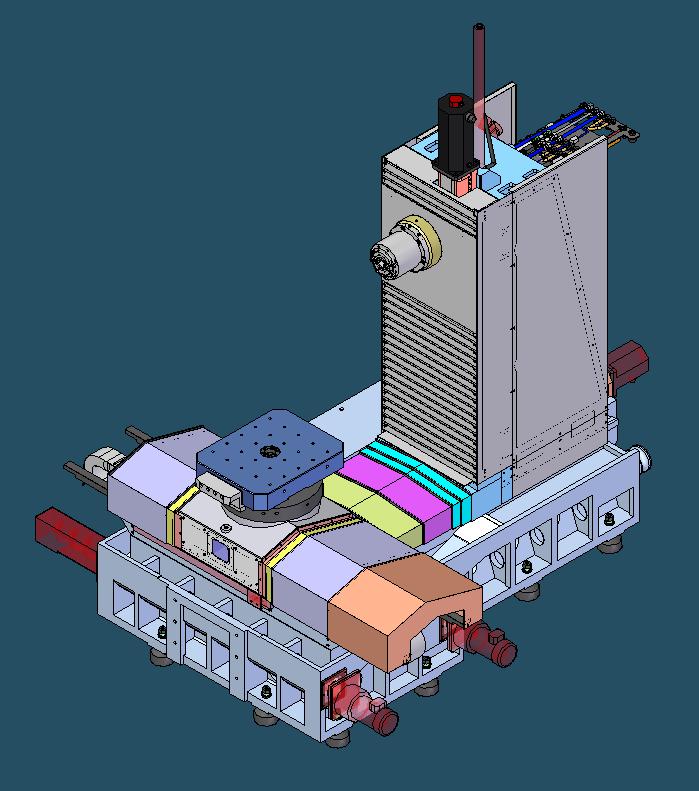

The machine is mainly composed of base, column, sliding saddle, indexing table, exchange table, headstock, cooling, lubrication, hydraulic system, fully enclosed protective cover and numerical control system. The tool magazine can be equipped with disc or chain type.

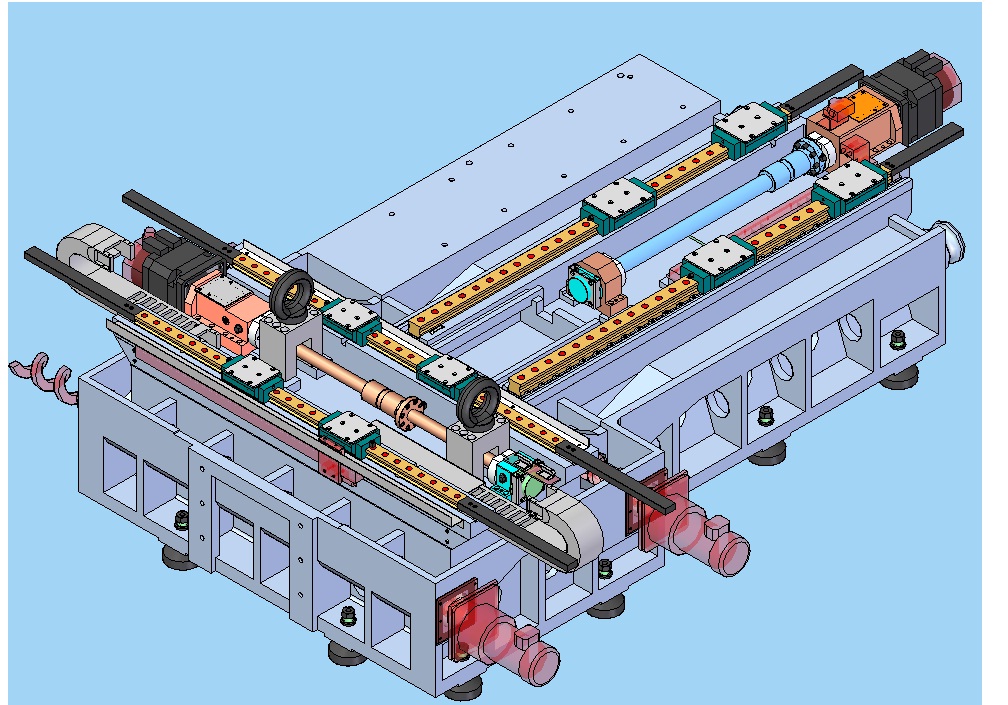

Base

In order to improve the anti-vibration performance, the bed of the horizontal machine is proposed to adopt the inverted T-shaped layout with the best vibration resistance in the world, with a box-shaped closed structure, and the front and rear beds are integrated. The bed is equipped with two linear rolling guide installation reference planes for the movement of the worktable and the column. Considering the convenience of chip removal and the collection of coolant, it is planned to set up chip flutes on both sides of the bed.

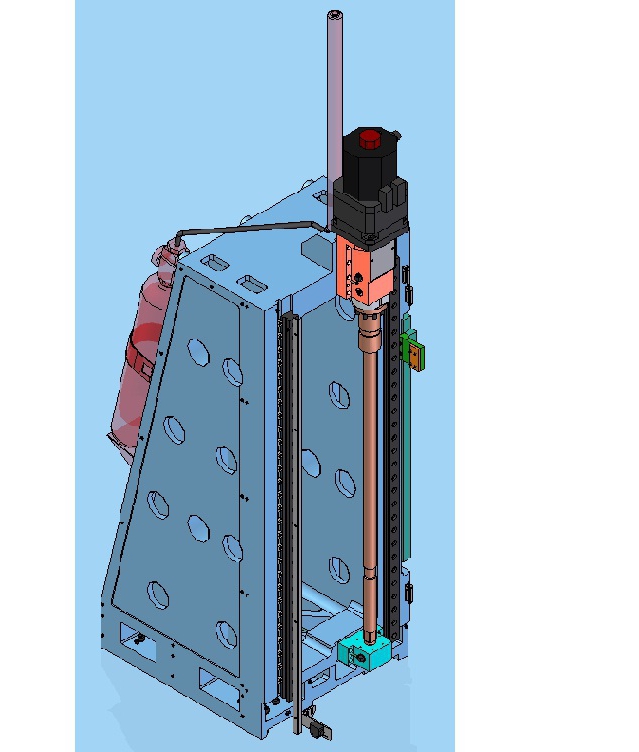

Column

The vertical column of the horizontal machine is planned to adopt a double-column closed symmetrical frame structure, with longitudinal and transverse annular ribs arranged in the cavity. On both sides of the column, there are joint surfaces for the installation of the linear rolling guide for the movement of the headstock (the installation reference surface of the linear guide). In the vertical direction (Y-direction) of the column, in addition to the guide rails for the headstock movement, there is also a ball screw and motor coupling seat between the two guide rails that drive the headstock to move up and down. High-speed stainless steel shields are considered on both sides of the column. The guide rails and lead screws are reliably and safely protected.

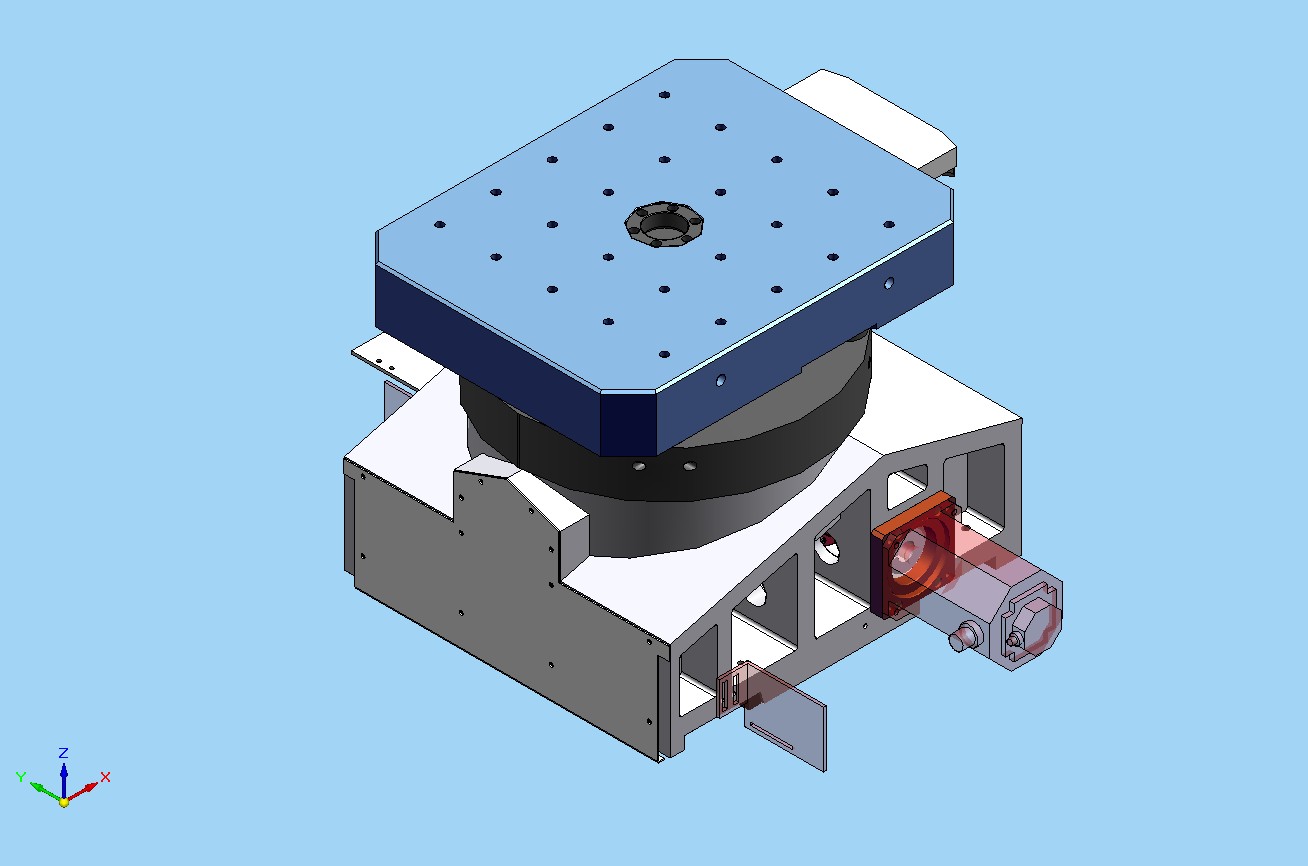

Rotary table

The worktable is accurately positioned and locked by servo, and the minimum indexing unit is 0.001°

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,