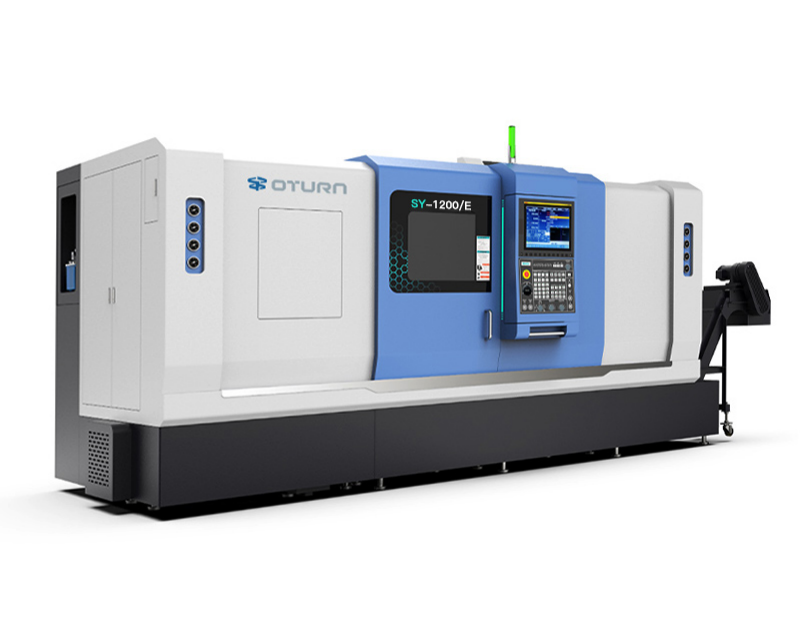

OTURN Slant Bed CNC lathes are cutting-edge machines commonly used in the manufacturing sector, especially in high-precision and high-efficiency environments. When compared to traditional flat-bed lathes, slant-bed CNC lathes offer superior stability and rigidity, making them perfect for machining complex and intricate workpieces.

Key Structural Features of a CNC Slant Bed Lathe:

Slant-Bed Design: The bed of a slant-bed CNC lathe is inclined at an angle typically ranging from 30° to 45°. This slanted design effectively reduces cutting forces and friction, enhancing the stability and rigidity of the machine.

Spindle System: The spindle serves as the core component of the lathe. It is equipped with precision bearings that can handle substantial cutting forces while ensuring a consistent rotational speed, which is critical for maintaining machining accuracy.

Tool System: These lathes feature a highly adaptable tool system, which supports a variety of machining operations, including turning, milling, and drilling. Additionally, automated tool changers boost efficiency by enabling fast and smooth transitions between tools.

Numerical Control (NC) System: Advanced NC systems are integrated into slant CNC lathe, allowing for complex programming and automation. This results in improved machining precision and operational efficiency.

Cooling System: To manage the heat generated during the cutting process, a cooling system is incorporated. Whether using sprays or liquid coolant, the system helps maintain a lower temperature for both the tools and workpieces, ensuring high-quality finishes and prolonging tool lifespan.

How a CNC Slant Bed Lathe Works:

Program Input: The operator inputs the machining instructions into the NC system. These instructions include the machining path, cutting parameters, and tool choices.

Workpiece Fixation: The workpiece is securely attached to the lathe's table, ensuring that it remains stationary throughout the machining process.

Tool Selection and Positioning: Based on the inputted program, the NC system automatically selects the right tool and positions it as per the machining requirements.

Cutting Process: The tool begins to cut the workpiece, powered by the spindle. Thanks to the slant-bed design, cutting forces are effectively distributed, reducing tool wear and increasing precision.

Completion: After the machining is complete, the NC system halts the tool's movement, and the operator can remove the finished part from the machine.

Key Precautions for Safe and Efficient Use:

Routine Maintenance: Regular maintenance is essential to ensure that all components function properly, helping to extend the lifespan of the machine.

Program Verification: Always double-check the machining program before starting the operation to avoid potential accidents caused by programming errors.

Tool Inspection and Management: Regularly inspect tools for wear and tear. Replace worn-out tools promptly to maintain the quality and consistency of machining operations.

Safe Operation: Strictly follow the operating guidelines to ensure the safety of the operator and prevent mishandling-related accidents.

Environmental Control: Keep the workspace clean and well-maintained. A clean environment is crucial for maintaining machine accuracy and performance.

By following these best practices, the OTURN slant-bed CNC lathe ensures optimal performance, precision, and efficiency across a wide range of machining applications.

Post time: Sep-21-2024