High performance CNC lathe play a crucial role in modern manufacturing. You can rely on these machines to deliver unmatched precision and efficiency. They handle intricate designs with ease, helping you achieve high production standards. By reducing waste and cutting costs, CNC Lathe also promote sustainable practices. CNC lathe suppliers ensure you access the latest technology to stay competitive.

Key Takeaways

- CNC Lathe provide excellent accuracy and make parts the same.

- They work nonstop, speeding up production and cutting waiting time.

- Using CNC Lathe saves money by automating work and reducing waste.

The Role of CNC Lathe in Modern Manufacturing

What Are CNC Lathe?

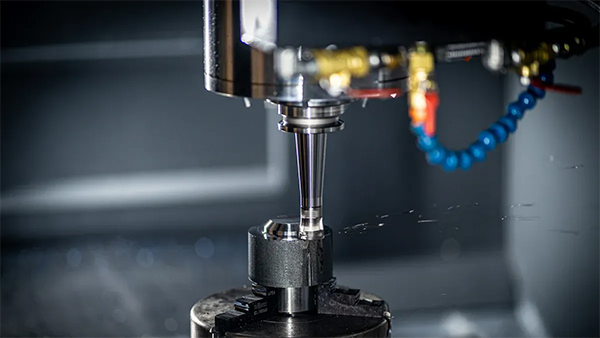

CNC lathe is an advanced machine for machining metals, alloys, and other hard materials into precise shapes. They use computer numerical control (CNC) technology to automate the cutting, drilling, and turning processes. You program the machine with specific instructions, and it follows them with incredible accuracy. Unlike traditional Lathe, CNC Lathe don’t rely on manual operation. This makes them faster and more reliable for producing consistent results.

How CNC Lathe Revolutionize Production Processes

CNC Lathe have transformed how manufacturers create products. These machines allow you to produce parts with unmatched precision and repeatability. They eliminate human error, ensuring every piece meets exact specifications. You can also handle large production runs without sacrificing quality. CNC Lathe work around the clock, boosting productivity and meeting tight deadlines. Their ability to process complex designs means you can innovate without limitations.

Key Benefits of CNC Lathe

Precision and Consistency in Manufacturing

CNC Lathe deliver unmatched precision in manufacturing. You can rely on these machines to produce parts that meet exact specifications every time. Unlike manual methods, CNC Lathe eliminate inconsistencies caused by human error. This ensures that every product you create is identical, even in large production runs. Whether you’re crafting intricate aerospace components or simple machine parts, CNC Lathe guarantee consistent quality.

Enhanced Efficiency and Faster Production Times

Speed is critical in modern manufacturing, and CNC Lathe excel in this area. These machines operate continuously without breaks, allowing you to meet tight deadlines. You can program them to handle multiple tasks in one setup, reducing downtime between operations. This efficiency not only speeds up production but also helps you deliver products to market faster.

Cost-Effectiveness Through Automation and Waste Reduction

CNC Lathe save you money by automating processes and minimizing waste. Automation reduces the need for manual labor, lowering operational costs. These machines also use materials efficiently, cutting only what’s necessary. This precision reduces scrap and helps you make the most of your resources. By partnering with reliable CNC lathe suppliers, you can access advanced machines that further enhance cost savings.

Versatility in Handling Complex Designs and Diverse Materials

CNC Lathe adapt to a wide range of manufacturing needs and can handle complex designs means you can create intricate parts without limitations. Whether you’re producing medical devices or automotive components, CNC Lathe offer the flexibility you need to innovate and stay competitive.

Applications of CNC Lathe Across Industries

Automotive: High-Performance and Durable Components

In the automotive industry, precision and durability are essential. CNC Lathe help you create high-performance components like engine parts, gears, and shafts. These machines ensure every part meets strict quality standards, which is critical for vehicle safety and performance. You can also rely on CNC Lathe to handle large production volumes without compromising accuracy. By working with CNC lathe suppliers, you gain access to advanced machines that keep your production lines efficient and competitive.

Aerospace: Meeting Stringent Safety and Precision Standards

Aerospace manufacturing demands extreme precision. CNC Lathe allow you to produce intricate parts like turbine blades and landing gear components. These machines meet the industry’s strict safety and quality requirements. Their ability to work with lightweight yet durable materials, such as titanium and aluminum, makes them indispensable. Partnering with reliable CNC lathe suppliers ensures you stay ahead in this highly regulated field.

Medical: Customization and Intricate Part Production

The medical field benefits greatly from CNC lathe technology. You can use these machines to create customized implants, surgical tools, and other intricate devices. CNC Lathe provide the precision needed for medical applications, where even the smallest error can have serious consequences. Their versatility allows you to work with biocompatible materials, ensuring patient safety. By choosing the right CNC lathe suppliers, you can meet the growing demand for high-quality medical components.

Other Industries Leveraging CNC Lathe Technology

CNC Lathe are not limited to automotive, aerospace, or medical applications. Industries like electronics, energy, and consumer goods also rely on these machines. You can use CNC Lathe to produce everything from circuit board components to household appliances. Their adaptability makes them a valuable tool across diverse sectors. Trusted CNC lathe suppliers can help you find the right machine for your specific needs, ensuring optimal performance and productivity.

CNC Lathe VS Traditional Machining Methods

Superior Accuracy and Repeatability

CNC Lathe offer a level of accuracy that traditional machining methods cannot match. You can program these machines to follow exact specifications, ensuring every part is identical. Traditional methods often rely on manual adjustments, which can lead to inconsistencies. CNC Lathe eliminate this issue by automating the process. For example, if you need to produce hundreds of identical parts, a CNC lathes ensures each one meets the same high standard. This repeatability is essential for industries like aerospace and medicine, where precision is critical.

Tip: Using CNC Lathe reduces the risk of errors, saving you time and resources in the long run.

Faster Production and Scalability

Speed is another area where CNC Lathe outperform traditional methods. These machines operate continuously without breaks, allowing you to complete projects faster. Traditional machining often requires manual intervention, which slows down production. With CNC Lathe, you can scale your operations easily. Whether you need to produce a small batch or a large volume, these machines adapt to your needs. This flexibility helps you meet tight deadlines and respond quickly to market demands.

Key Advantage: CNC Lathe can handle multiple tasks in one setup, reducing downtime and increasing efficiency.

Reduced Labor and Skill Dependency

CNC Lathe simplify the manufacturing process, reducing your reliance on skilled labor. Traditional machining requires experienced operators to make precise adjustments. In contrast, CNC Lathe only need a well-prepared program to function. This automation allows you to focus your workforce on other critical tasks. It also makes it easier to train new employees, as they don’t need extensive machining experience.

Note: By investing in CNC Lathe, you can lower labor costs while maintaining high-quality production.

FAQ

What industries benefit the most from CNC Lathe?

CNC Lathe are widely used in industries like automotive, aerospace, medical, electronics, and energy. Their versatility makes them essential for producing precise and complex components.

Tip: Explore CNC lathe applications in your industry to unlock new possibilities for innovation and efficiency.

How do CNC Lathe improve production efficiency?

CNC Lathe automate processes, reducing downtime and increasing output. They handle multiple tasks in one setup, ensuring faster production while maintaining consistent quality.

Are CNC Lathe suitable for small businesses?

Yes, CNC Lathe suit small businesses. They reduce labor costs, improve precision, and allow you to scale production efficiently. Many suppliers offer affordable options tailored to smaller operations.

Key Insight: Investing in CNC Lathes can help small businesses compete with larger manufacturers by improving productivity and quality.

Post time: Mar-19-2025