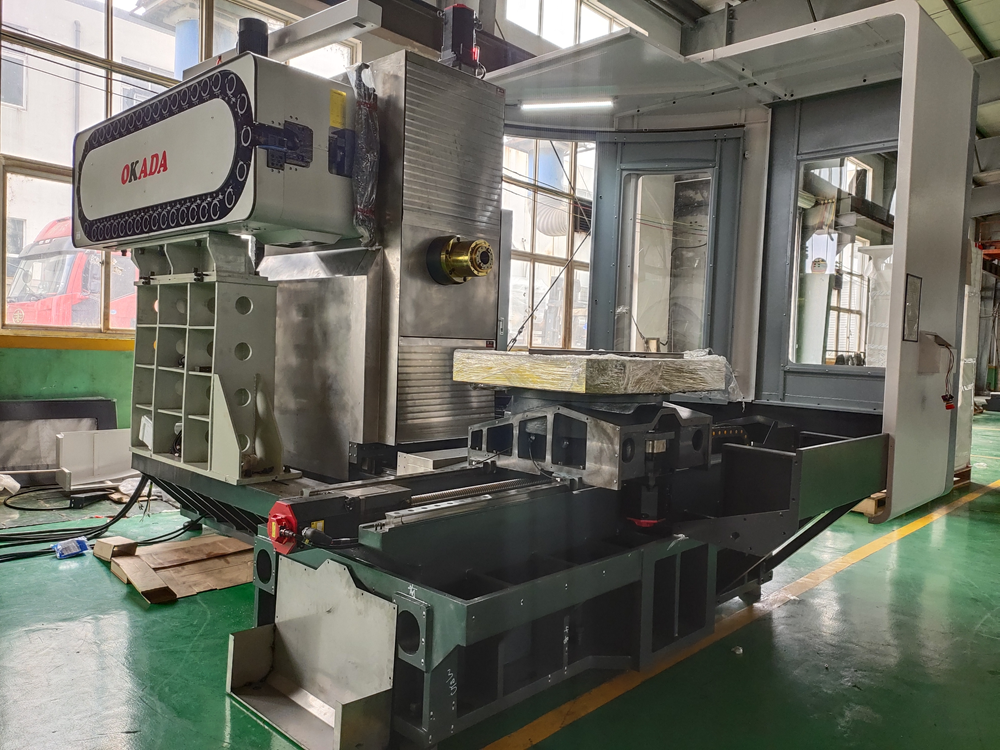

The horizontal machining center is suitable for processing parts with complex shapes, many processing contents, high requirements, multiple types of ordinary machine tools and numerous process equipment, and multiple clamping and adjustments to complete the processing.

The main processing items are as follows:

Parts with both flat surfaces and holes

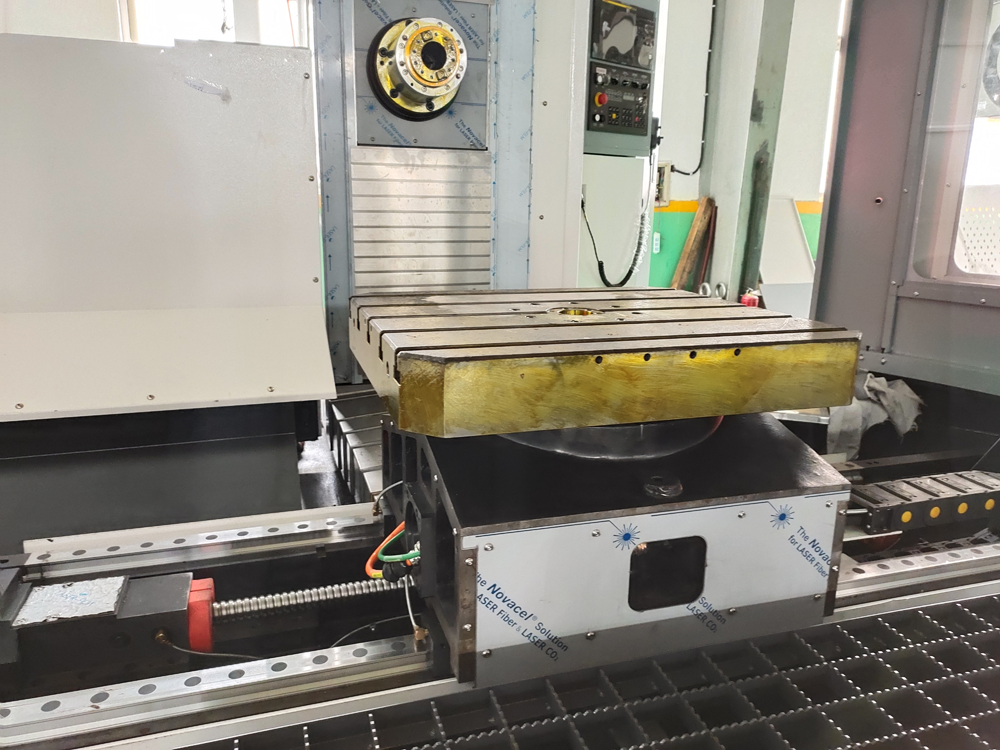

The dual-table horizontal machining center has an automatic tool changer. In one installation, it can complete the milling of the surface of the part, the drilling, boring, reaming, milling and tapping of the hole system. The processed parts can be on one plane or on different planes. Therefore, the parts with both plane and hole system are the processing objects of the machining center, and the common ones are box-type parts and plate, sleeve, and plate-type parts.

1. Box parts. There are many box-type parts. Generally, multi-station hole system and plane processing are required. The accuracy requirements are high, especially the shape accuracy and position accuracy are strict. Usually, milling, drilling, expansion, boring, reaming, countersinking, and tapping are required. Waiting for the work steps, there are many tools required, it is difficult to process on ordinary machine tools, the number of tooling sets is large, and the accuracy is not easy to guarantee. The last installation of the machining center can complete 60%-95% of the process content of the ordinary machine tool. The accuracy of the parts is good, the quality is stable, and the production cycle is short.

2. Discs, sleeves and plate parts. There are planes, curved surfaces and holes on the end faces of such parts, and some holes are often distributed in the radial direction. Vertical machining center should be selected for disc, sleeve, and plate parts whose machining parts are concentrated on a single end surface, and horizontal machining center should be selected for parts whose machining parts are not on the surface in the same direction.

3. Special-shaped parts refer to parts with irregular shapes such as brackets and shift forks. Most of them are mixed processing of points, lines and surfaces. Due to the irregular shape, ordinary machine tools can only adopt the principle of process dispersion for processing, which requires more tooling and longer cycle. Utilizing the characteristics of multi-station point, line and surface mixed processing of the machining center, most or even all of the procedures can be completed.

Post time: Dec-13-2021