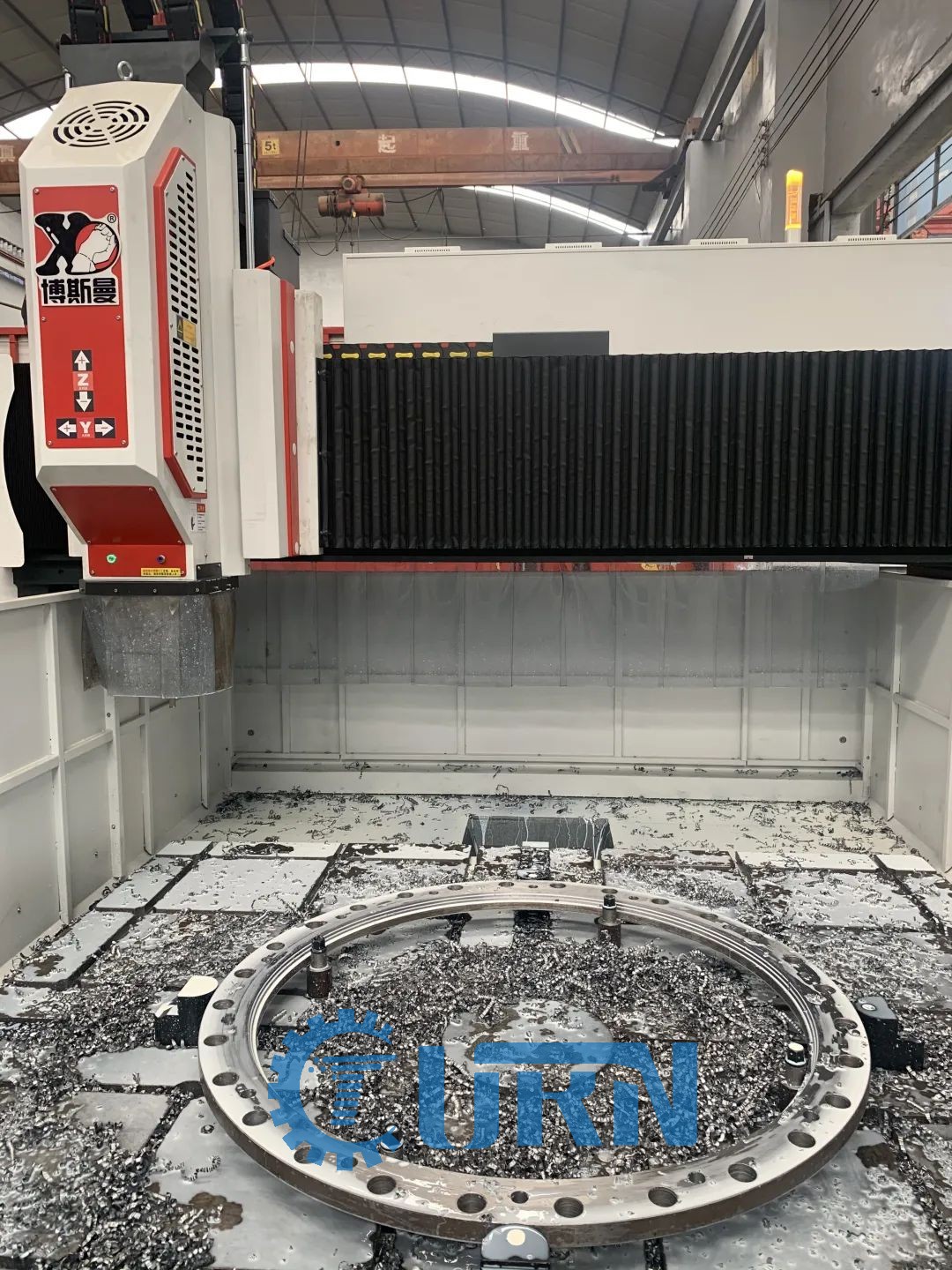

Through the control of the computer, the CNC drill machine performs automatic positioning according to the program and automatically adjusts to the best feed amount according to different hole diameters.

This processing mode of CNC drill machine is widely used in all walks of life, and its obvious advantages are favored by everyone.

Precision of CNC drill machine√

In terms of machining accuracy, the uncertainty caused by artificial hole machining is relatively high. When the error is too large, it is easy to cause the workpiece to be scrapped and cause losses to the enterprise. The drill machineuses CNC positioning, the positioning accuracy of the hole can reach within ± 0.1mm, and the products produced meet the processing requirements.

High efficiency of CNC drilling √

Compared with artificial holes, CNC drilling is more efficient. The CNC drill adopts the automatic CNC machining method, the drilling efficiency is higher than that of manual work, and the quality and precision of the product are also improved. Artificial hole processing is not only inefficient, but also has many and cumbersome processing procedures, low product precision, and unsatisfactory product quality.

The benefit of CNC drilling is also much higher than that of traditional artificial hole processing. When processing the CNC drilling machine, two labor costs are saved. This processing method can be completed in only 0.5 hours. The work efficiency and the economic benefits of the enterprise are improved. The traditional artificial hole processing, scribing, drilling, proofing, punching and positioning, drilling and tapping all require one person. As a general estimate, it takes 3.0 hours to process a tube sheet.

CNC drill reduces labor √

The traditional method of hole processing and positioning relies on skilled workers to draw lines according to the drawings, and then use electric hand drills or magnetic drills to drill the positioning holes, which is inefficient and has large errors. Now using the CNC drill machineonly needs to input specific parameters through the computer, and according to the correct CAD design drawing, the automatic continuous large-aperture processing of the drilling power head can be realized, the convenience of operation is improved, the high precision of product and the high stability of production is guaranteed.

The processing of large-diameter holes √

The CNC drill machineis characterized by automatic CNC positioning for the processing of large-aperture holes. Large-aperture holes do not require secondary reaming, and can be formed in one processing. Compared with the traditional manual positioning, drilling and reaming, it is much more accurate.

Post time: Apr-19-2022