The epidemic at the end of 2019 has caused many factories to be unable to put into normal production for a long time, such as the flange manufacturing factory in Wenzhou China we mentioned today. For businessmen who frequently visit China, they may know Wenzhou, a city with very developed manufacturing industry, and most of the people working in this city come from other places. Suffering from the severe impact of the epidemic, many workers from other places were unable to return to the factory to work on time. Workers who can go to work in time are also far from being able to meet production requirements because of time constraints.

The fundamental reason for this situation is that this factory still uses the most traditional processing method,such as radial drills and a lathe, one machine needs to be matched with one worker. Driven by today’s market that pursues high efficiency and low cost, squeezing labor and increasing working hours have long been unable to meet the needs of an enterprise that wants to gain a foothold in today’s market.

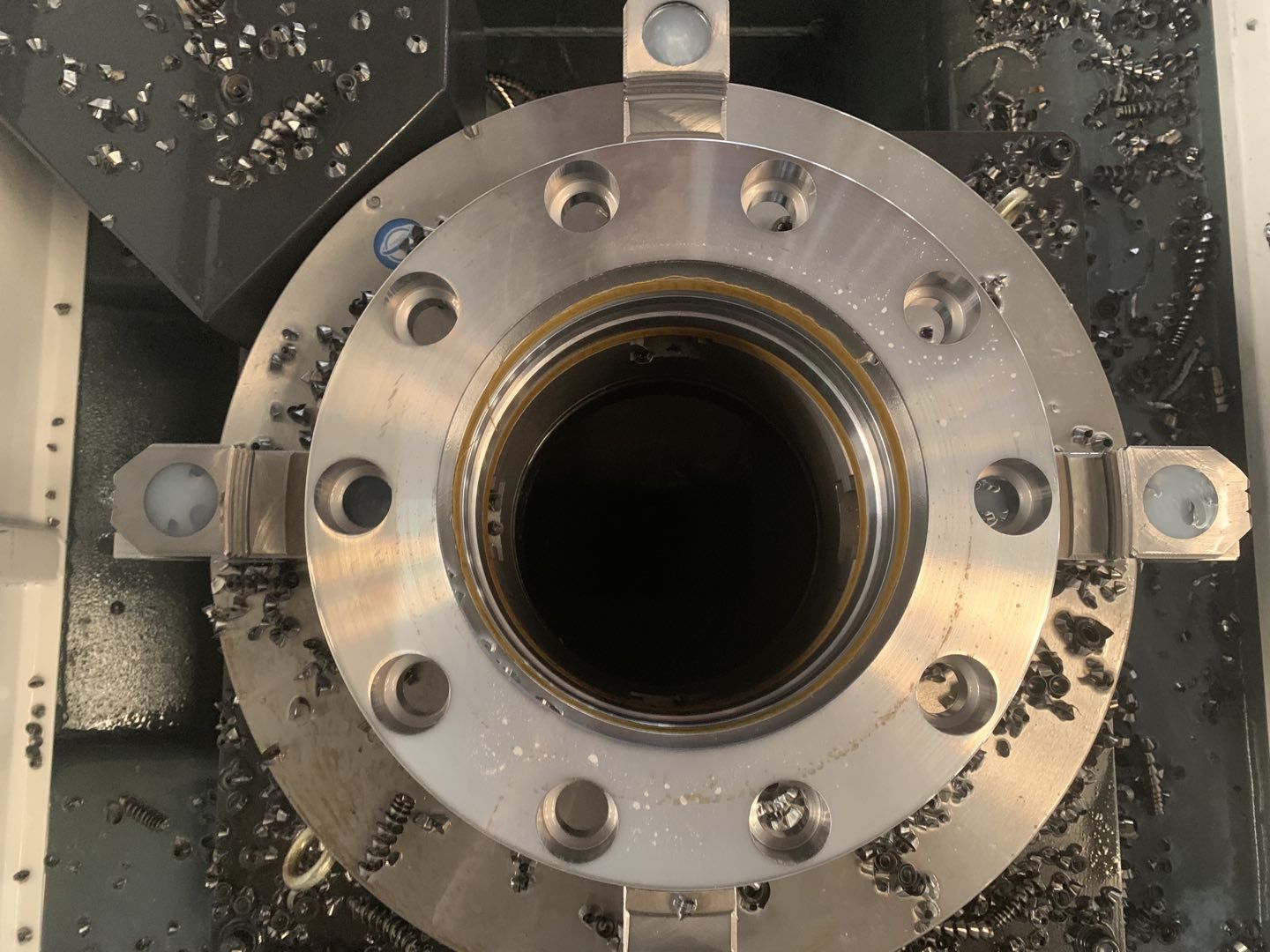

According to the boss talking later, he had been suffering for a long time. Although there are a large number of orders on hand, but it is unable to give customers a timely delivery date, so that some old customers are looking for new suppliers one after another. Occasionally the boss saw BOSM CNC drilling and milling machine on Tiktok China. The video he cleary remember it is a CNC four-station flange drilling machine, which can process flanges in four stations in a cycle. Suddenly his eyes lit up, thinking that this was the kind of processing he wanted most.Not only is the efficiency high, but also the worker clamps the flange quickly. Later, they tried to contact BOSM. By viewing more video processing cases shared by our sales, the boss became more and more interested. After communicating with the technical engineers of our factory, they learned that the current flange diameter of less than 500mm accounted for 80% of the workpieces, and the time processing beats Compared with the calculation they worked before, the efficiency is at least 8 times higher than before, and it does not require so many workers to operate.

In 2020, the boss successively purchased two more machines,one is high-speed CNC drilling and milling machine BOSM-DT1616 and the other one is also four-station flange drilling machine. At present, only one operator in the workshop can operate the three machines.

In the face of difficulties, thinking changes, and only by change can there be meet better opportunities and development. Seeing this boss again this year, he can already drink tea leisurely, and his expression is more relaxed and cheerful than before. He said that using the right and efficient machines is more effective than trying to reduce labor costs and reduce the quality. BOSM’s CNC drilling and milling machines have indeed helped us achieve the improvement of efficiency and quality, and the reduction of labor costs.

Post time: Aug-31-2021