The butterfly valve was previously positioned as a leakage valve and was only used as a valve plate.

It was not until 1950 that synthetic rubber was actually used, and synthetic rubber was applied to the seat ring of the butterfly valve, and the butterfly valve as a cut-off valve made its debut.

Classification of butterfly valves:

Butterfly valves are classified according to structure, piping connection, plate, etc.

Center Disc butterfly valve:

A structure in which the seat surface on the outside of the valve flap is on the same surface as the center of the valve stem.

The inner peripheral surface of the valve body is embedded with the structure of the rubber seat ring. This is the valve represented by the so-called center-shaped rubber plate butterfly valve. According to the compression of rubber, the elastic repulsive force of the butterfly valve and the seat surface is effectively utilized, so that good seat sealing is possible.

Eccentric butterfly valve:

The rotation center (stem) of the disc is on the center of the valve diameter, and the base of the disc is an eccentric structure. The seat ring is the same as the single eccentric shape and has a good sealing performance.

Tri-eccentric butterfly valve:

It is a structure in which double eccentricity is added, and the cone center of the butterfly plate is inclined from the center of the valve diameter of the occasion.

The triple eccentricity does not touch the plate-shaped metal seat ring when the butterfly plate is opened and closed, and only the butterfly plate exerts a pressing force on the seat ring as the shut-off valve when it is fully closed.

Wafer butterfly valve:

The wafer butterfly valve uses stud bolts to connect the valve between the two pipe flanges. There are two types of protrusions, full lug type and incomplete lug type.

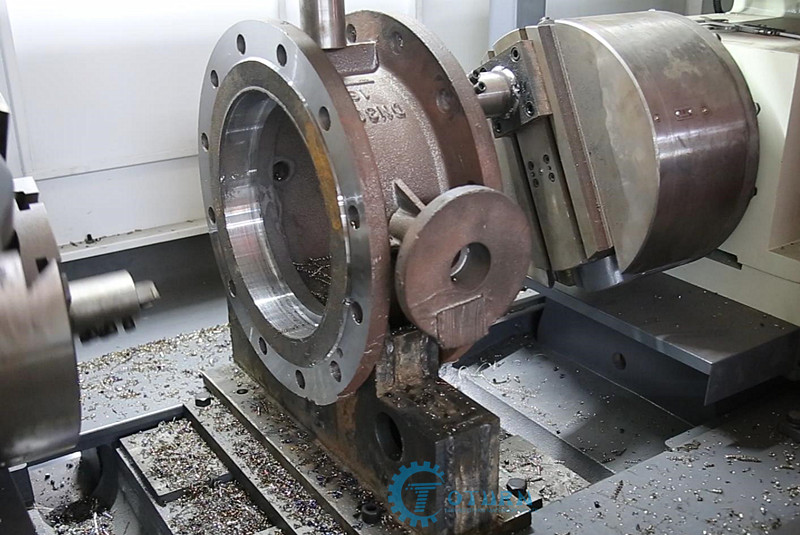

These valves can be processed by our Special Valve Machine.

Post time: Jul-01-2021