Horizontal CNC drilling and milling machine is designed for fast drilling of workpieces with dimensions over 800mm in three dimensions of valves/reducers, which require rotating indexing in four-sided or multi-sided machining. Most of the holes of such valve-type polyhedron parts are less than 50mm in diameter, requiring surface milling and boring. Horizontal CNC drilling and milling machine is equipped with a 1000mm*1000mm square worktable or a 1200mm CNC minute.Degree plate, indexing accuracy 0.001 degrees.The scrap iron will fall down automatically into the scrap remover so that it is easy to remove the scrap. Horizontal CNC drilling and milling machine does not install protection for cast iron parts. It is equipped with 24 tool magazine as standard and needs to be equipped with large surround protection when internal cooling is used.

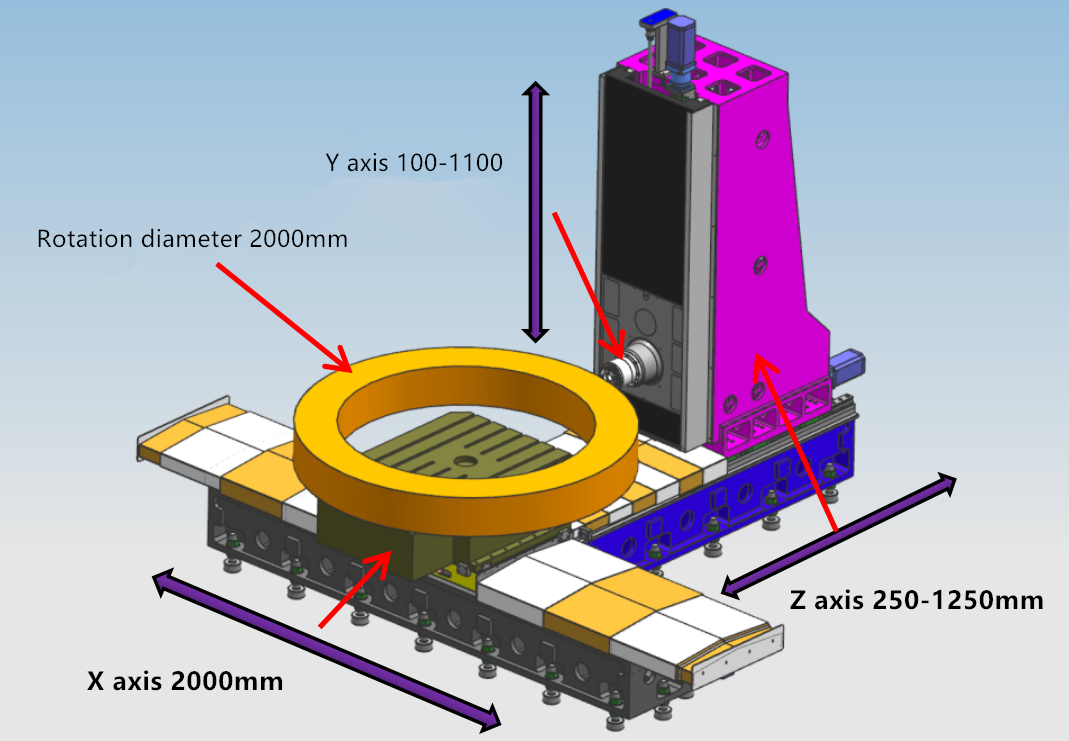

Horizontal CNC drilling and milling machine covers a small area, and open machine is convenient for lifting workpieces. It is suitable for factories with limited space. It is suitable for application and processing (valve type).Horizontal CNC drilling and milling machines are capable of highlighting high speed and efficiency. The coordinate travel of the machine tool is 2000 mm laterally, 1000mm front and rear, 1000mm up and down, ensuring the processing of workpieces with a rotary diameter of 2000 mm. Horizontal CNC drilling and milling machines employ the horizontal four-axis positioning method and the locking function of CNC rotary indexing discs to ensure the indexing accuracy and rigidity requirements during machining.

Horizontal CNC drilling and milling machines compete for the market of boring machines and horizontal products, such as 1000mm type CNC boring machines or horizontal machining centers, which are very expensive in the market. Our market is for workpieces that do not require very high machining accuracy. We have high processing efficiency and price advantage.

Post time: Oct-13-2021