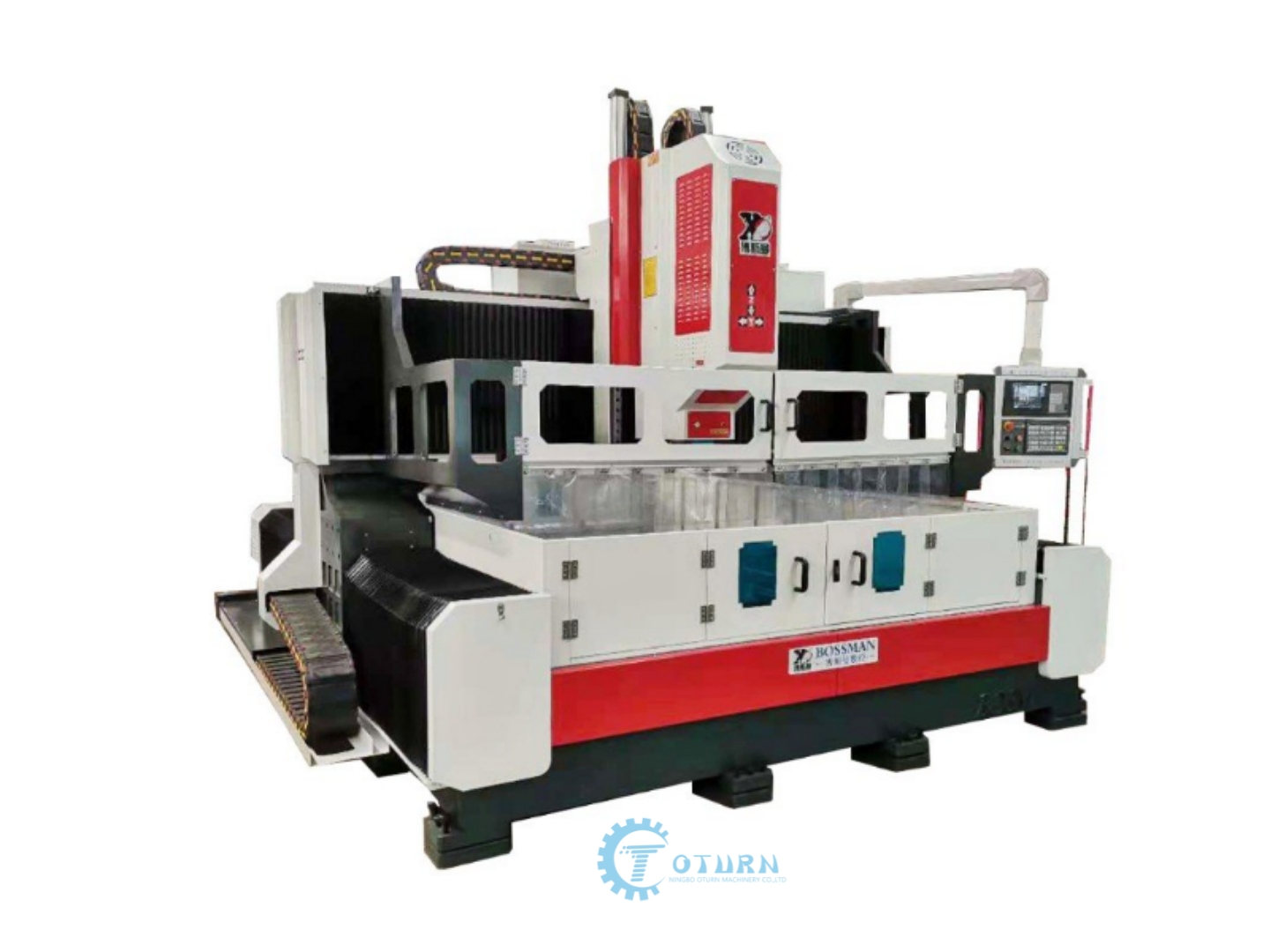

Commissioning of CNC Drilling and Milling Machine:

Drilling and milling machine is a kind of high-tech mechatronics equipment. It is very important to start and debug correctly. This determines to a large extent whether the CNC machine tool can exert normal economic benefits and its own service life.

Check before starting up: check the surrounding environment of the drilling machine, whether there is any abnormal phenomenon such as water in the electrical box, and whether the oil has deteriorated.

Step-by-step startup: The power supply voltage of the machine tool must be checked before startup. The power supply switch of the machine tool must be turned on after the main power switch is turned on for about 10 minutes and the voltage is stable, and then turn on other power switches in the electrical box to check whether the voltage is a missing phase and If it is too low, turn on the power of the machine tool if there is no abnormality, and observe whether there is any abnormality or air leakage. Do not perform any actions when there is no alarm when the machine is turned on, and let the electrical components energize for 30 minutes.

Slow movement: Check whether there is interference, move the machine tool during the whole process with the handwheel, and pay attention to whether there is any abnormality, and then perform the origin return step.

Machine tool running-in: Run the machine tool automatically and slowly for a long time and then rotate the spindle at low speed.

Post time: Aug-17-2021