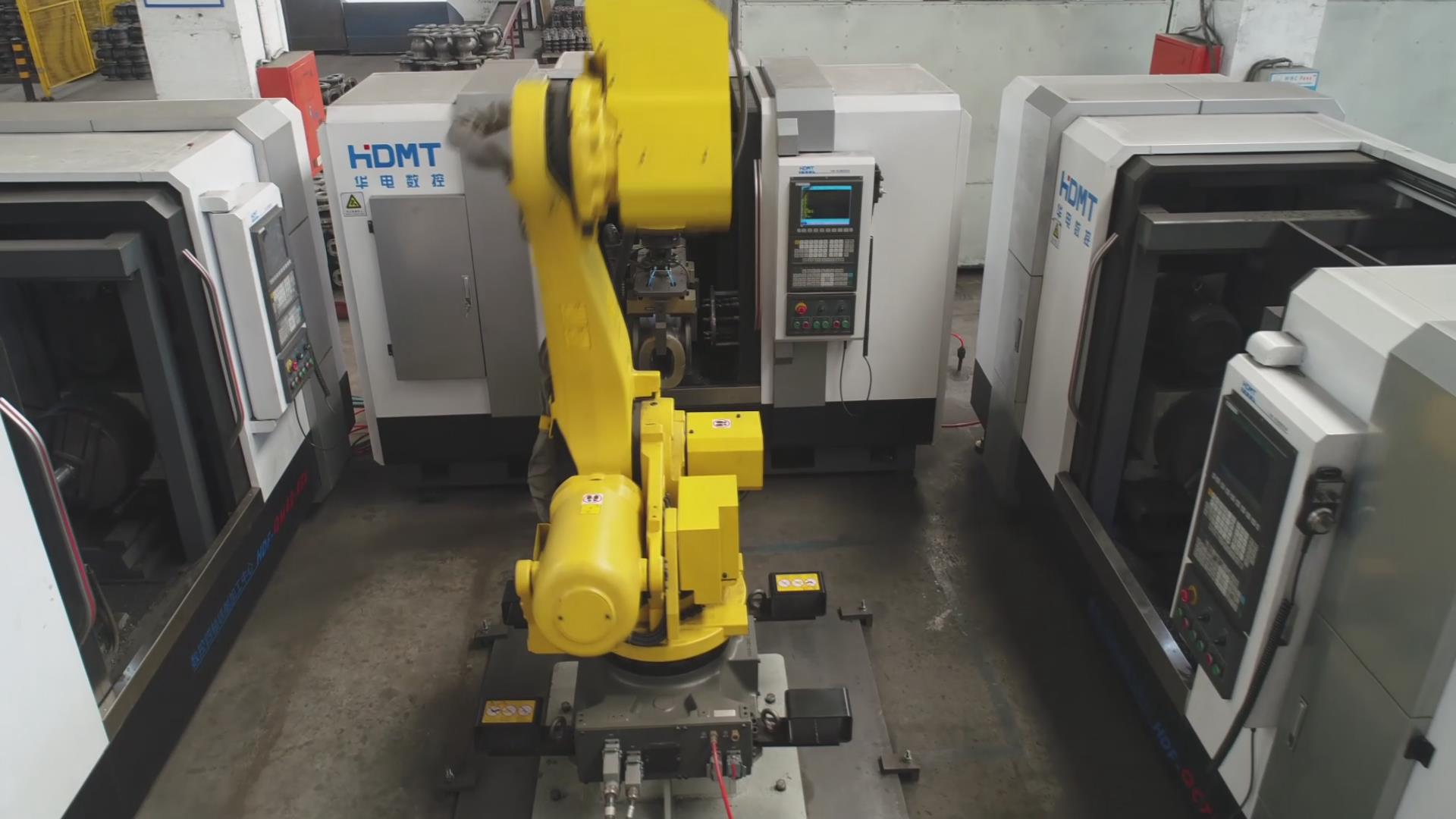

In China, where labor costs are rising and human resources are scarce,robots have begun to be widely used in various fields, and workers who replace valve manufacturing lines with robots are also accepted in many well-known valve factories.

A well-known valve factory in Denmark was affected by the Covid-19, and employees were unable to finish the workload as required with limited working time. This gave customers the idea of using robots to replace the manual operations, and the application of this production line has been mature in China and has been recognized by customers.

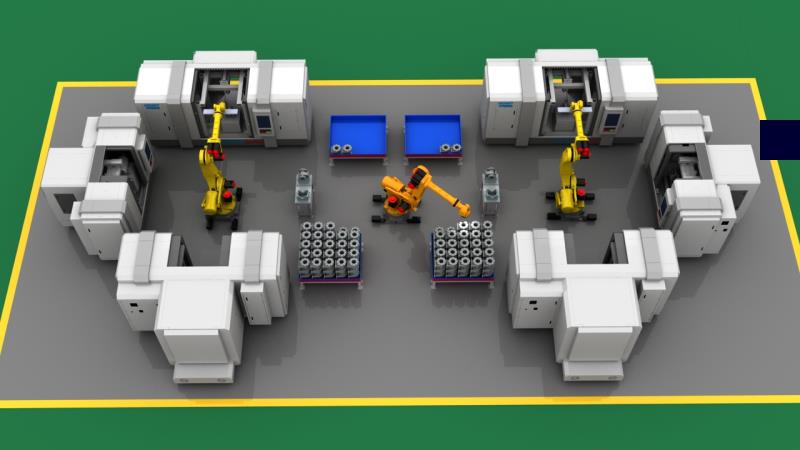

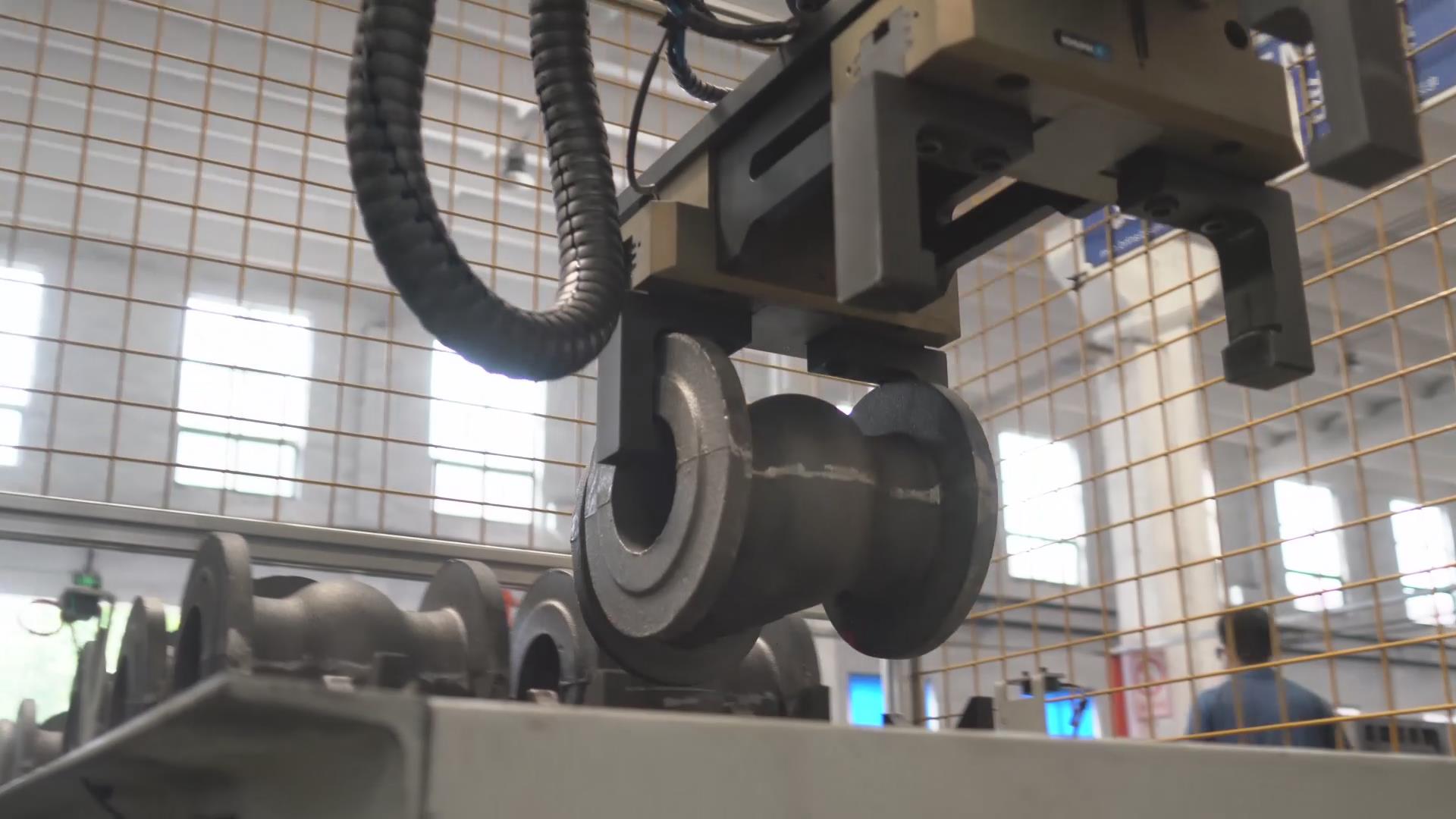

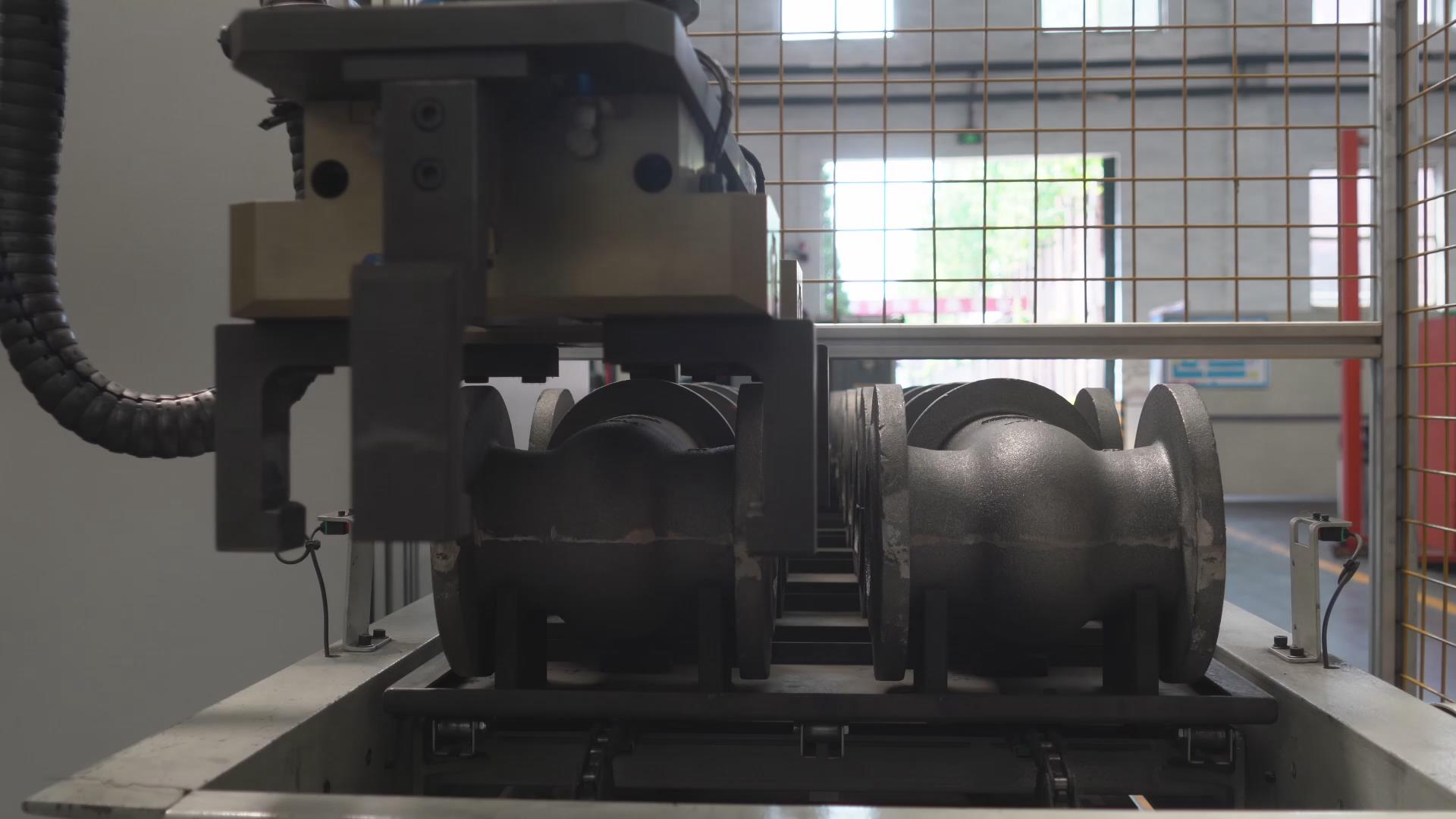

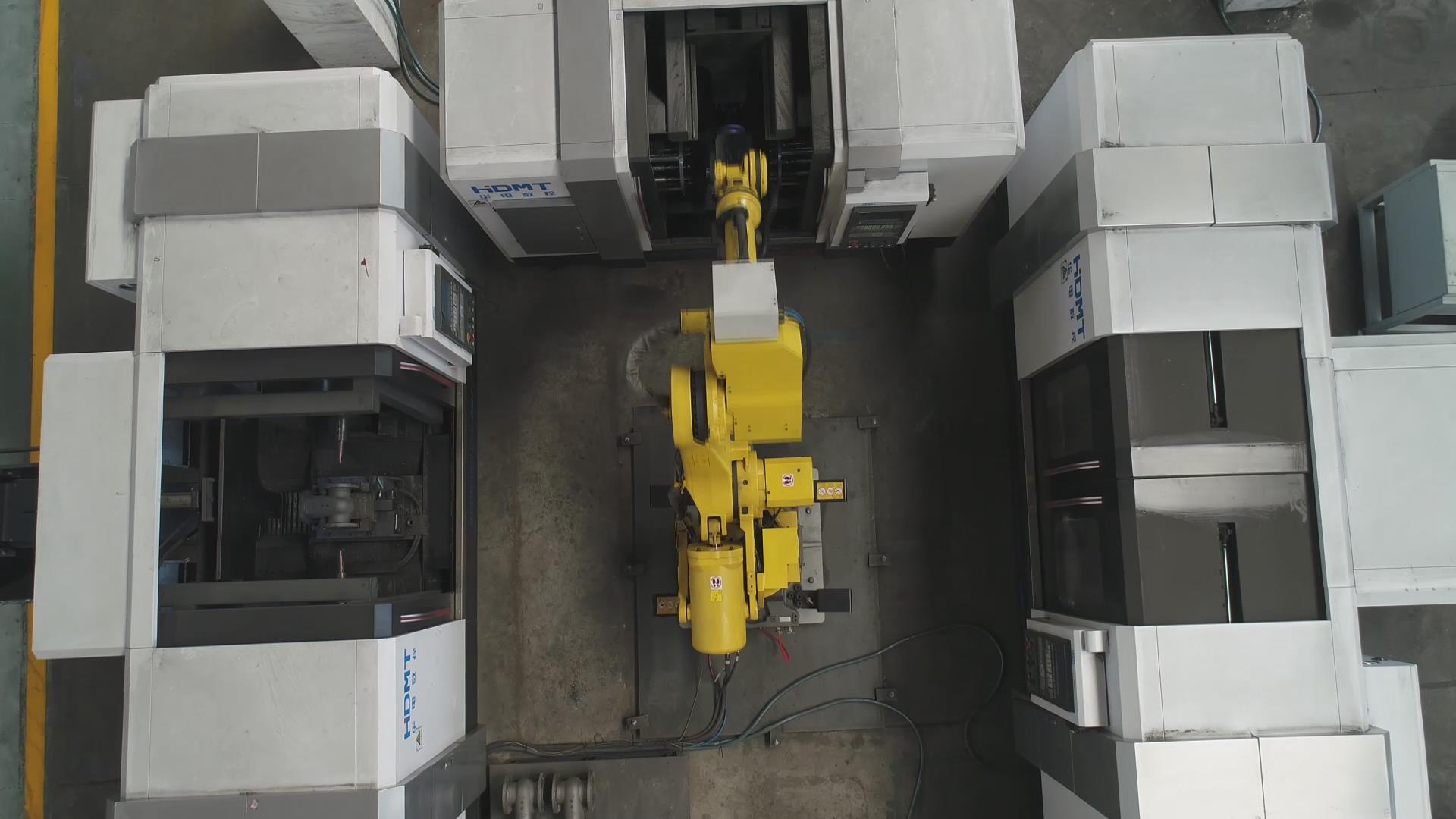

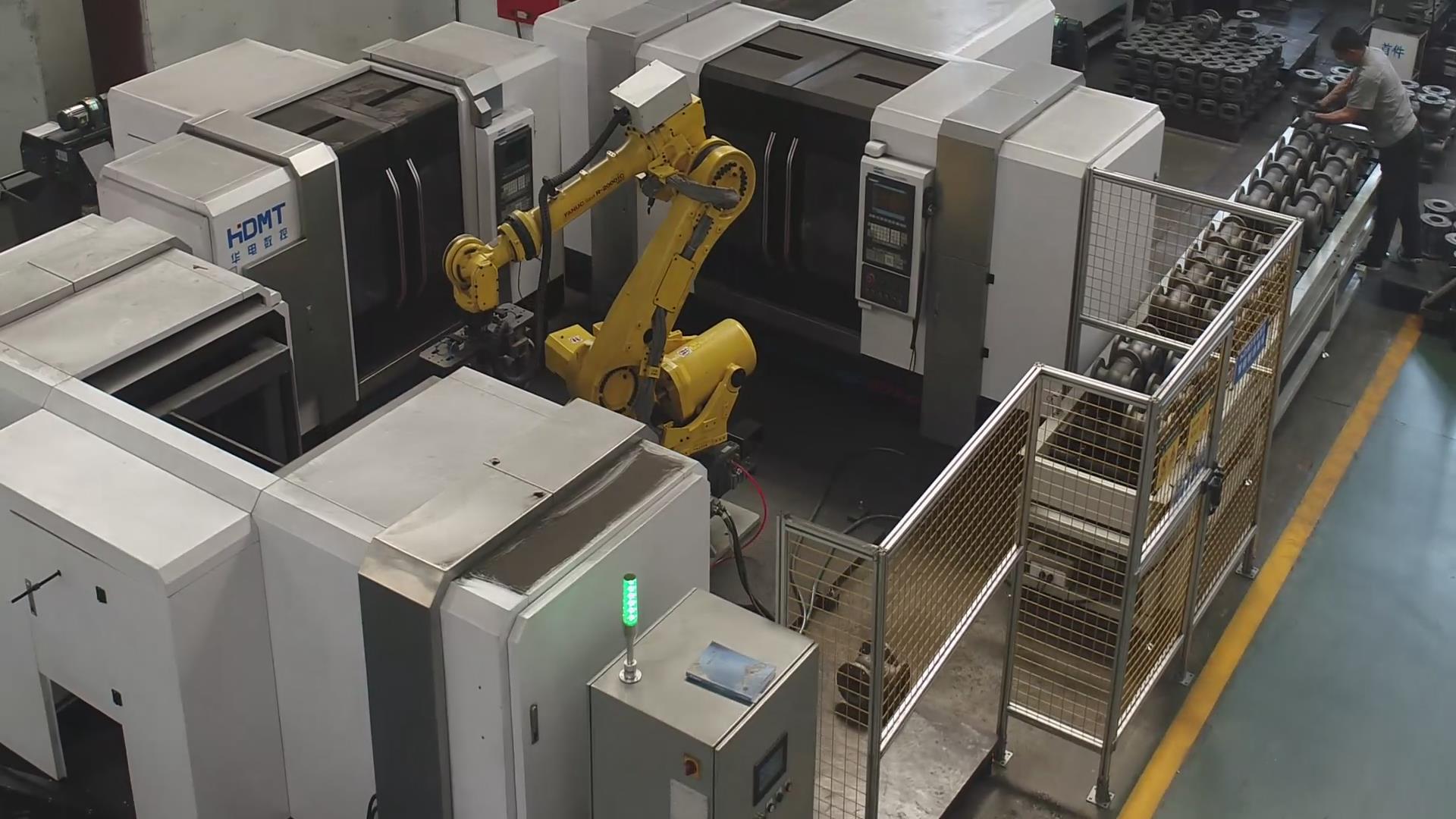

We have designed the solutions for the processing gate valve bodies.

The three machines are:

CNC Three face turning machine,to realize turning of the three flange faces of the gate valve at the same time.

Horizontal hydraulic Three Side Drilling Machine ,to realize drilling on the three flange faces at the same time.

Two Side CNC Sealing Machining Machine,to realize simultaneous processing of the 5 degree angle inside the valve body.

Robots replace manual production to save labor costs. At the same time, robots can achieve 24-hour operation, requiring only one robot to look after three machines. In addition, the automatic assembly line production mode can save more space, make the planning of the factory more compact, and save the cost of land resources.

Post time: Mar-16-2021