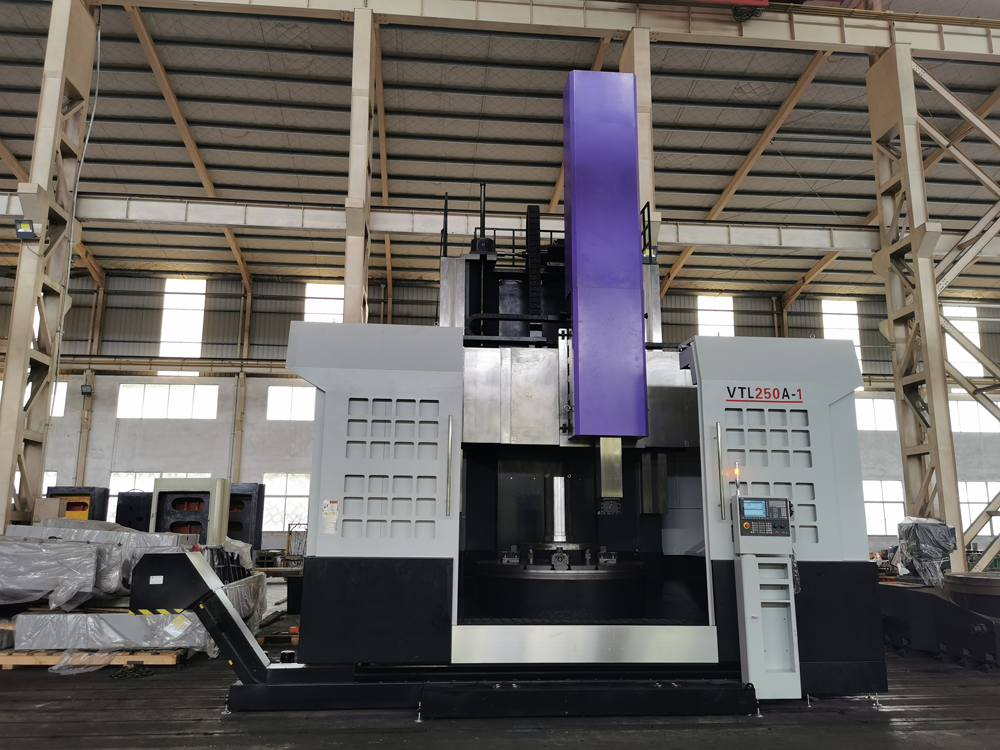

Large-scale CNC vertical lathes are large-scale machinery, which are used to process large and heavy workpieces with large radial dimensions and relatively small axial dimensions, and complex shapes. For example, the cylindrical surface, end surface, conical surface, cylindrical hole, conical hole of various discs, wheels and sets of workpieces can also be processed with the help of additional devices for threading, spherical surface, profiling, milling and grinding.

The auxiliary time of the large-scale CNC VTL Machine is very short. It can complete all the processing content in one clamping. Try to choose the open fixture with high rigidity, which can not interfere with the tool path, and can complete the processing of the workpiece within the range of the spindle stroke. As a highly automated machine tool, various alarms will appear after a period of use. Some are system failures, some are improper parameter settings, and some are mechanical failures. Fan alarms are one of them.

When such a situation occurs, check the internal fan first. If it does not turn, take it apart and see. If it is too dirty, wipe it clean with alcohol or gasoline before installing it. If there is an alarm, you have to replace the servo amplifier. HC appears. Current alarm, mainly to detect abnormal current on the DC side, first look at the servo parameters, and then remove the motor power line. During the period, there is an alarm to replace the servo amplifier. There is no alarm. Exchange the motor and power line with other axis to determine whether it is the motor or the power line. Problem: If J appears on the display, it depends on whether it is a PC problem. Check whether the motherboard, interface conversion board and PCRAM control board device are correct, replace and debug until the cause is determined, and then troubleshoot the problem.

When such a situation occurs, check the internal fan first. If it does not turn, take it apart and see. If it is too dirty, wipe it clean with alcohol or gasoline before installing it. If there is an alarm, you have to replace the servo amplifier. HC appears. Current alarm, mainly to detect abnormal current on the DC side, first look at the servo parameters, and then remove the motor power line. During the period, there is an alarm to replace the servo amplifier. There is no alarm. Exchange the motor and power line with other axis to determine whether it is the motor or the power line. Problem: If J appears on the display, it depends on whether it is a PC problem. Check whether the motherboard, interface conversion board and PCRAM control board device are correct, replace and debug until the cause is determined, and then troubleshoot the problem.

What are the matters needing attention in the maintenance of large CNC VTL Machining?

1. After starting the main motor each time, the spindle cannot be started immediately. Only after the lubrication pump is working normally and the oil window comes with oil, the spindle can be started to let the machine tool work.

2. The screw can only be used when turning threads to ensure its accuracy and life.

3. Maintain the inside and outside of the machine tool to be clean, the machine parts are complete, the screw rods and polished rods are oil-free, and the guide rail surfaces are clean and intact.

4. Do the lubrication work of each lubrication point according to the specified requirements (see the label instructions of the machine tool lubrication system for details).

5. Regularly check and adjust the tightness of the V-belt of the CNC vertical lathe.

6. Pay attention to check the working condition of the oil pump to ensure that the headbox and feed box have enough lubricating oil. The lubricating oil in each tank shall not be lower than the center of each oil standard, otherwise the machine tool will be damaged due to poor lubrication.

7. Clean the oil filter copper mesh of the oil filter in the oil inlet of the bedside box every week to ensure that the lubricating oil is clean.

8. When the spindle is rotating at a high speed, under no circumstances should you pull the shifting handle.

Post time: Nov-24-2021