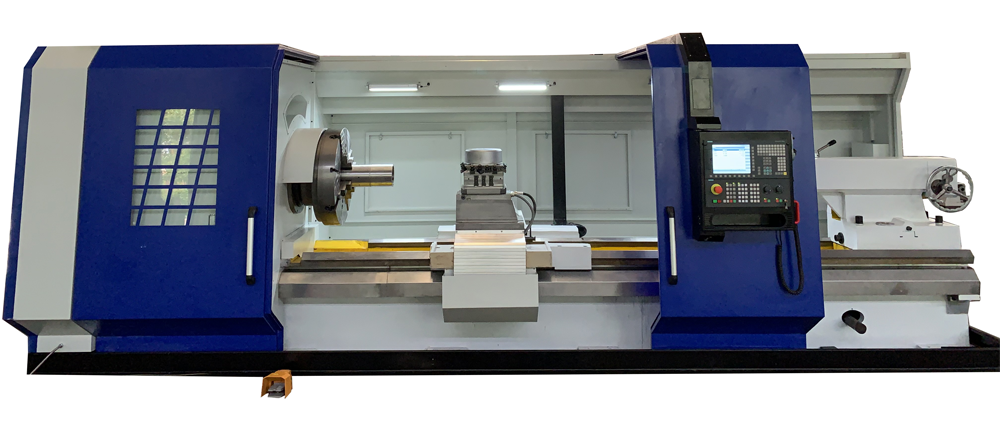

The CNC pipe threading lathe can process various thread surfaces and revolving surfaces, and is suitable for turning all kinds of pipe threads. In order to machine the required surface of the workpiece, the tool and the workpiece must maintain accurate relative motion, which is realized by the software system. The movement of the spindle of a pipe threading lathe is the main movement, and the accuracy of its transmission directly affects the quality of the machined surface.

Although the pipe threading lathe is a special lathe for the oilfield industry, it can also be used as a traditional lathe. The cutting power is related to the selected tool material, workpiece material and cutting amount.

We often encounter some CNC machine tool dealers who will ask us to change the spindle design of pipe thread lathes based on the experience of traditional lathes to make it completely the same as the spindle structure of general CNC lathes, so as to ensure the universality of the tools. But such customization is impossible. The following is a detailed introduction to the spindle of the oil country lathe.

The spindle part of the pipe thread lathe is one of the important components of the machine tool, including the support of the spindle and the transmission parts installed on the spindle. Due to the high speed, high power, and manual adjustment of CNC machine tools during processing, good rotation accuracy, structural rigidity, shock resistance, thermal stability, wear resistance and accuracy retention of components are required. In order to realize automatic loading and unloading and clamping on the spindle, there must be an automatic clamping device for the tool, a spindle stop device and a clear cutting device.

The front support of the pipe thread lathe spindle adopts double-row cylindrical roller bearings with inner tapered bore to bear the radial force, which improves the radial rigidity of the spindle and the rotation accuracy of the spindle. Two thrust ball bearings are used to bear the axial force and reduce the axial movement of the spindle. Momentum improves the axial rigidity of the spindle. The rear support adopts double row cylindrical roller bearings with inner tapered bore, which play a role of radial support.

The CNC pipe thread lathe is developed and designed for the turning of oil field pipe threads, and is suitable for turning all kinds of pipe threads. The output characteristics of the spindle directly affect the stability and high precision of the machine tool. Because it is very necessary to analyze and study the dynamic characteristics of the spindle unit. Through the modal analysis of the spindle, the influence of the rationality of its structure on the accuracy of the machine tool is studied, and the relevant components are optimized to meet the requirements of the machine tool for processing quality and accuracy.

Post time: Nov-20-2021