Selection principle of CNC machine tools when machining valve parts:

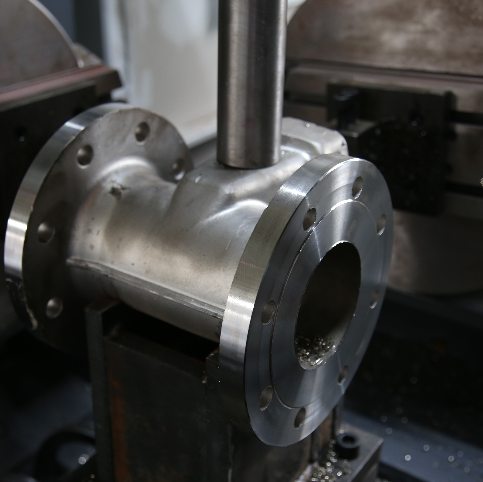

① The size of the machine tool should be compatible with the outline size of the valve to be processed. Large machine tools are used for large parts, so that the equipment can be used reasonably. A vertical lathe should be selected if you want to process valve bodies, valve covers, etc.; or parts with large rotating diameters and short lengths, especially large-diameter butterfly valves, which can usually be done several meters, and must be processed with a vertical lathe. In addition, the rotation diameter of the fixture is often larger than the co-rotation diameter of the workpiece, and attention should be paid when selecting a machine tool, otherwise there may be interference between the fixture and the bed.

② When processing valve parts, the selection principle of CNC machine tools is that the accuracy of the machine tool should be adapted to the accuracy required by the process. When finishing the sealing surface, the required geometric shape accuracy is high, and a high-precision machine tool should be selected.

③The productivity of the machine tool should be adapted to the production type of the workpiece. To choose high-efficiency automated machine tools, if medium or mass production is required, this can ensure stable production, and stable production is also a major factor in high efficiency.

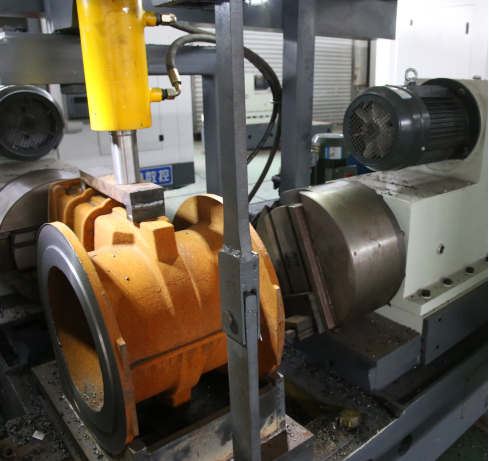

Ours automatic three-head CNC machine tool, special designed for pump body/pipe fitting/valve automatic machining line. With exclusive patents, it can realize three heads turning&milling&boring imultaneously, the whole machining procedure is realized by machines and robots automatically without manual intervention.

Post time: Feb-15-2022