The 19th China International Machine Tool Exhibition (CIMT 2025) was grandly held from April 21 to 26, 2025, at the New China International Exhibition Center Phase II in Shunyi, Beijing. As one of the world’s top four machine tool exhibitions, CIMT 2025, themed “Integration, Innovation, and Intelligent Future,” gathered over 2,400 enterprises from 31 countries and regions. Covering an exhibition area of 310,000 square meters, it attracted more than 150,000 professional visitors, creating a lively and unprecedented event atmosphere.

Hot Machines on Display, Leading Future Technology

At the exhibition, several top machines became industry highlights, drawing numerous customers to experience them firsthand.

TM-1500S

High-end Five-Axis Turning-Milling Compound Center

The TM-1500S integrates the functions of multiple conventional machines, significantly reducing operation time and labor costs. It offers excellent machining performance by minimizing thermal displacement and improving machining accuracy, easily handling high-precision tasks. Designed ergonomically for easy operation and maintenance, it provides an ideal solution to meet customer demands. This fully closed-loop five-axis turn-mill center delivers outstanding performance and powerful functions. It can operate as a highly efficient five-axis precision lathe or a turn-mill center, enabling autonomous, high-precision, and cost-effective six-sided complete machining. It is widely used in precision engineering, aerospace, mechanical engineering, and medical technology.

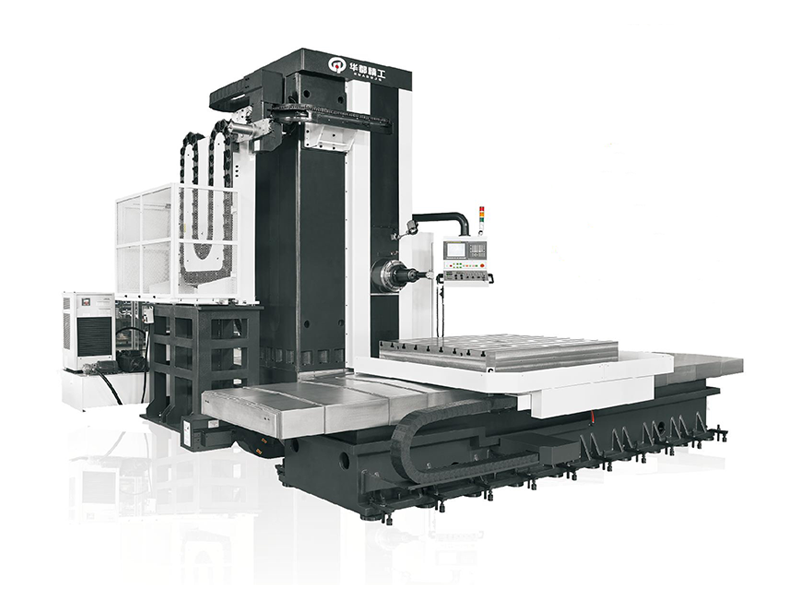

HBM130T3

CNC Boring and Milling Machine

This five-axis turn-mill composite center features a powerful 2838NM high-torque spindle suitable for heavy cutting. The rotary table has a standard load capacity of 8,000kg, with optional capacities ranging from 10,000 to 25,000kg. The Z-axis can continuously bear an axial load of 2,000kgf, ensuring strong cutting force at high torque and speed. The spindle uses oil cooling and nitriding treatment to prevent thermal deformation and wear. The X/Y axes employ direct coupling transmission to improve efficiency. The machine’s high-rigidity cast iron structure ensures stability and long-term high-precision machining.

A13

Five-Axis CNC Horizontal Machining Center

Featuring a moving column structure, this five-axis machining center achieves five-axis linkage for easy machining of complex surfaces. Its lightweight design allows a rapid linear axis movement speed of up to 90m/min and acceleration of 1G, greatly enhancing efficiency. The A and B axes use direct drive with zero backlash and high rigidity, combined with high-precision angle encoders for accurate positioning. The T-shaped bed and stepped guide rail layout on the X-axis optimize force distribution and reduce moving part weight. The high-speed electric spindle operates quietly at high speeds. Three linear axes use roller guides with low friction and high rigidity.

On-site communication and interaction, sparking wisdom

At the exhibition, our technical team actively engaged with customers and industry experts, gaining deep insights into their needs and providing professional answers and customized solutions for various machining challenges. Through face-to-face communication, we showcased the technical strengths of China’s high-performance CNC equipment and earned high recognition and trust from clients.

Company Strength and Professional Service

OTURN, as an industry-leading overseas marketing center, always adheres to the core values of “Professionalism, Focus, Efficiency, Simplicity, Excellence, and Altruism.” We not only provide advanced CNC equipment but also tailor complete production line solutions for our customers, helping enterprises optimize production processes, improve machining efficiency, and enhance product quality. With rich industry experience and a comprehensive after-sales service system, OTURN is committed to becoming a trusted partner for our clients, jointly promoting the intelligent upgrade of the manufacturing industry.

The Exhibition Is in Full Swing — We Look Forward to Welcoming You!

CIMT 2025 is ongoing with vibrant activities and continuous showcases of innovative technologies and advanced equipment. The OTURN team warmly invites you to keep following the event and visit our booth for in-depth exchanges. Together, let’s explore the future of intelligent manufacturing and seize this rare opportunity to advance toward a highly efficient, green, and smart new manufacturing era!

Post time: Apr-21-2025