CNC milling is one of the available CNC services. This is a subtractive production method because you will use this process to develop products with the help of special machines, which will remove parts from a block of material. Of course, the machine will use a special tool to cut off part of the material. Therefore, this is completely different from a 3D printing service, because in this process, you will use a 3D printer to create objects. CNC milling is therefore different, but it is used quite a bit. Below you will find three important facts to know.

Not all CNC machines are processed, which can be confusing. However, CNC refers to a technology, not a specific process. This technology is called computer numerical control, or therefore abbreviated as CNC. It can be applied to milling machines and lathes to use traditional processing techniques. However, CNC can also be used with 3D printers, water jet cutters, electrical discharge machines (ECM) and many other machines. If someone uses the term “CNC machining“, it is wise to ask them exactly what it means. They may mean CNC milling machines, but this is not always the case.

So not all CNC is milling, but all milling is actually machining. what is this? Machining is a subtractive mechanical process. This is so because it physically removes material from a work. The most common method is with the help of lathes and milling machines. These are a bit different. The mill uses a rotating tool to cut or drill off the material. When the workpiece is fixed in place, the tool will rotate rapidly. The lathe will switch these. Therefore, the workpiece will rotate in a fast manner, and the tool will slowly pass through the workpiece to remove material.

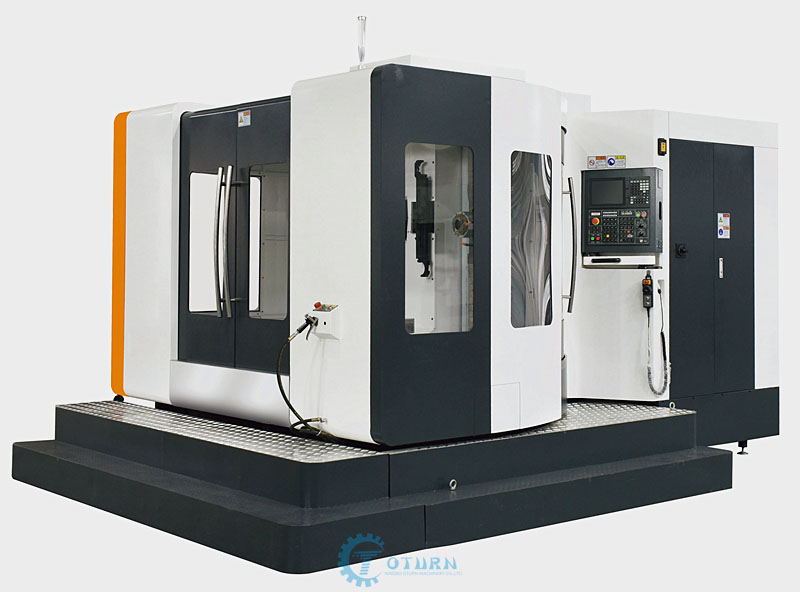

There are many types of mills, but the two most common are vertical mills and horizontal mills. This refers to the axis of motion starting from the tool. The two factories may look very similar, but if you look at them carefully, you can easily see some differences. Each type of milling machine has its own advantages and disadvantages. Generally, vertical mills are not only cheaper, but also smaller and easier to use than horizontal mills.

Custom CNC machining can be done in a variety of ways. The two most common CNC machining services are CNC milling and CNC turning services. These are the daily processes of the machining workshop. Both methods use cutting tools to remove material from solid workpieces. This will be used to create 3D products, which can also be done through online 3D printing. Both CNC milling and CNC turning are considered subtractive manufacturing methods. This is because they all remove material. There are some key differences between these two processes, which you can read below.

The term turning refers to the part because it rotates around the central axis. The cutting tool will therefore remain stationary and will not rotate. However, it will move. It goes in and out of the workpiece to create an incision. Turning is used to create cylinders and derivatives of cylinders. Examples of these parts are shafts and railings, but even baseball bats can be manufactured with the help of CNC turning. The workpiece will be fixed on the rotating spindle by a chuck. At the same time, the base holds the cutting tool so that it can move in or out radially along the axis. The rotation rate of the workpiece will affect the feed and speed, just like the radial depth of the cut and the rate at which the tool moves along the axis.

CNC milling is very different from CNC turning. During the milling operation, the tool will rotate. The workpiece will be fixed on the worktable, so it will not move at all. The tool can be moved in the X, Y or Z direction. Generally, CNC milling can create more complex shapes than CNC turning. It can produce cylindrical products, but it can also produce many other shapes. In a CNC milling machine, a chuck is used to fix the tool on the rotating spindle. The cutting tool will be moved to form a pattern on the surface of the workpiece. Milling does have a major limitation. This is about whether the tool can enter the cutting surface. Using thinner and longer tools can improve proximity, but these tools may deflect, resulting in poor product quality.

Post time: Jul-15-2021