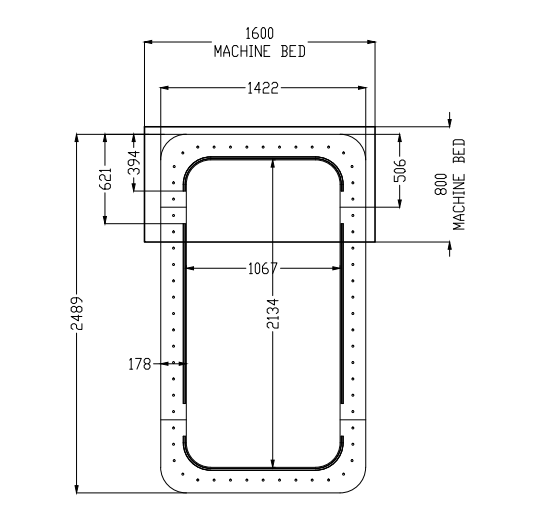

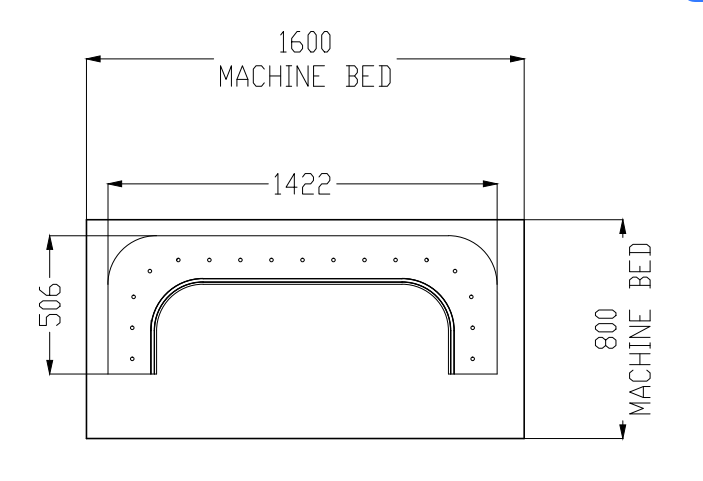

When customers contact us, they are distressed by the efficiency competition among their peers.At the beginning of the establishment of the factory, customers used radial drilling machine to process workpieces.With the popularity of CNC machines, he replaced a CNC vertical machining center to process workpieces.Customers use CNC vertical machining center to process electric boxes made of steel for several years. The main processing function is drilling machining.The customer told us: “Because the machining range of the machining center is limited and the machining efficiency is considered. we do it in multiple settings.”(As shown below)

Obviously, this is a very inefficient processing method.Now CNC drilling machines have been gradually used by many factories to process electric boxes.According to the current problems faced by customers, we recommend customers to choose special-purpose machines-CNC drilling and milling machines.BOSM CNC drilling and milling machine solves a lot of problems for customers.The entire workpiece can be clamped and processed by a CNC drilling and milling machine at one time.

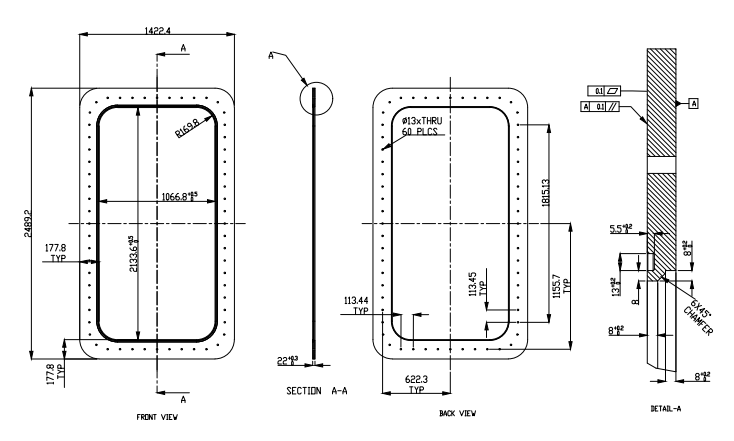

According to the size of the workpiece in the drawing, our engineers suggest to choose the CNC drilling and milling machines BOSM-DT2016.

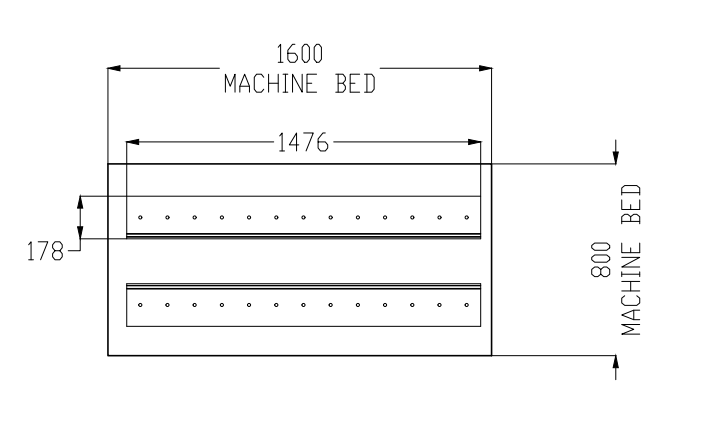

In order to change the tool, customers want to choose a tool magazine but feel that the price of disc tool magazine is slightly higher.Based on past experience, we recommend that customers choose a row-type tool magazine.The row-type tool magazine is installed on the CNC drilling and milling machine, which is cheaper and does not affect the original travel of the machine.

After we showed to customers a trial machining in the factory, the customer was very satisfied and determined the CNC drilling machine BOSM-DT2016.Now the customer has put CNC drilling machines into service, while vertical machining centers are idle

After using BOSM CNC drilling machine, more labor costs and time costs are saved, and there is no need to divide the workpiece into multiple parts for multiple loading and unloading.It can be processed once by CNC drilling machine. The efficiency is 60% higher than that of the previous radial drilling machine and 35% higher than that of the vertical machining center. The customer is quite satisfied with all aspects of the equipment and said that he will deepen cooperation again in the future.

Post time: Sep-28-2021