New Delivery for Cnc Gear Cutting Machine - Manual Pipe Threading Lathe Manufacturer – Oturn

New Delivery for Cnc Gear Cutting Machine - Manual Pipe Threading Lathe Manufacturer – Oturn Detail:

Machine Features

1. This conventional pipe threading lathe is a new design.

2. The bed is a unique three-layer wall structure, and the rear wall is arranged with a 12° slope. The guide rail width of the bed is 550mm. It is super-audio quenched and precision grounded to ensure the accuracy and service life of the machine.

3. The overall gear box type spindle unit, the headstock box is the overall casting structure, rather than the mat heightening block.

4. The application of quenching precision grinding gears and high-quality bearings ensures that the machine noise is good.

5. The main headstock adopts a strong external circulation cooling lubrication system, which not only reduces the temperature rise of the main shaft, but also effectively keeps the head box clean and lubricated.

6. The guide rail is attached with YT soft belt to improve the guiding precision and the precision of the machine tool, and effectively improve the service life of the machine tool.

7. The main drive gear is manufactured by Shenyang Machine Tool Group to ensure that the noise of the machine tool is good.

This machine tool is widely used in the processing of hydraulic cylinders, long shaft parts and various parts.

Specification

|

Item |

Unit |

QL1320 |

QL1323 |

|

Max.turning diameter of machine body |

mm |

630 |

630 |

|

Max.workpiece length |

mm |

1500 |

1500 |

|

Max.turning diameter of Tool holder |

mm |

350 |

350 |

|

width of Bed |

mm |

550 |

550 |

|

Spindle bore |

mm |

205 |

230 |

|

Three-jaw chuck |

mm |

205 |

230 |

|

Chuck specification |

|

Φ500 Manual three-jaw chuck |

Φ500 Manual three-jaw chuck |

|

Spindle speed |

r/min |

18-450 |

18-450 |

|

Main motor power |

kw |

11 |

11 |

|

Machining thread |

Metric thread |

550 |

550 |

|

|

1-15mm |

205 |

230 |

|

21 Kinds |

1-15mm |

205 |

230 |

|

21 Kinds |

|

Φ500 Manual three-jaw chuck |

Φ500 Manual three-jaw chuck |

|

|

Inch thread |

1-14tpi |

18-450 |

|

26 Kinds |

1-14tpi |

11 |

11 |

|

26 Kinds |

Metric thread |

|

|

|

Maximum longitudinal travel of the saddle |

mm |

1250 |

1250 |

|

Spindle center to Tool installation datum |

mm |

32 |

32 |

|

Tool section size |

mm |

32×32 |

32×32 |

|

Tailstock sleeve diameter |

mm |

100 |

100 |

|

Tailstock sleeve travel |

mm |

250 |

250 |

|

Taper of tailstock taper hole |

Mohs |

5 |

5 |

|

Lateral displacement of tailstock |

mm |

±15 |

±15 |

|

Machine weight |

Kg |

4500 |

4500 |

|

Machine size |

mm |

3300x1450x1500 |

3300x1450x1500 |

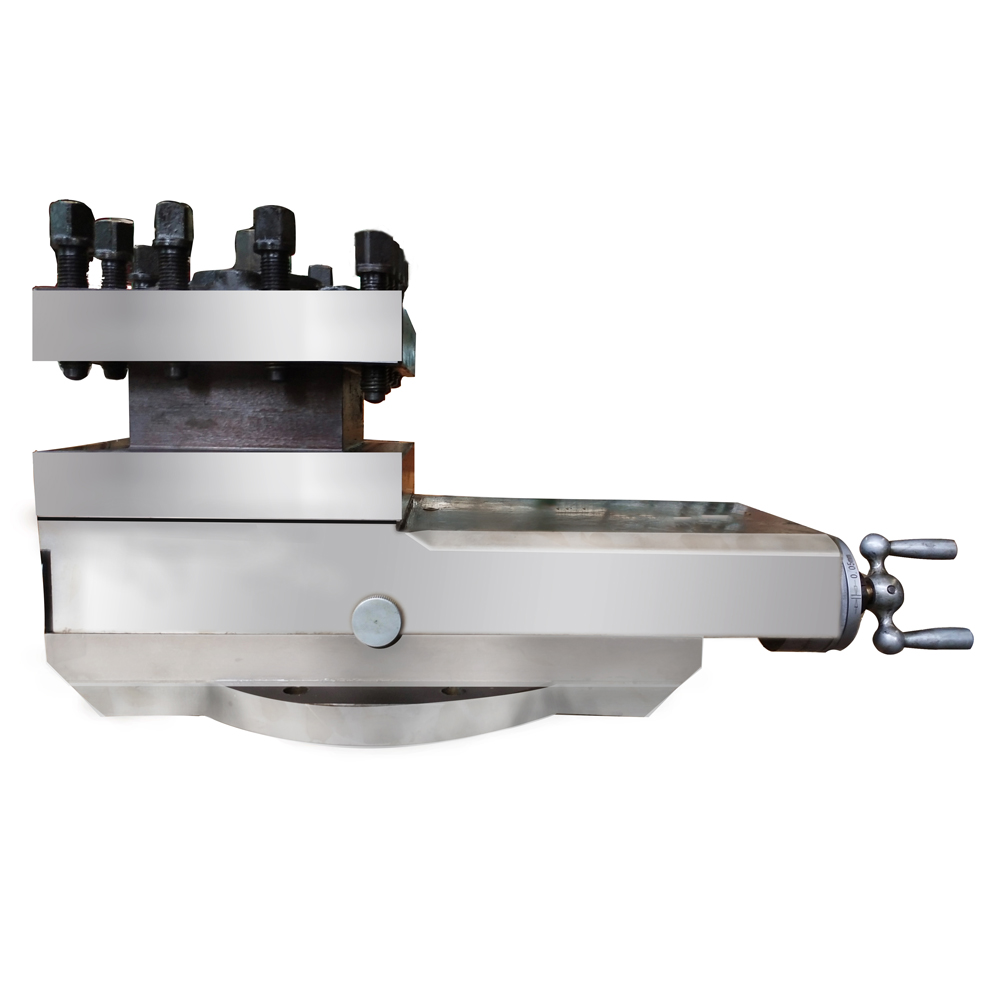

Detail Pictures

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.