Horizontal Dual-servo CNC Gear Grinding Machine CZL-24NCS

1.Machine features:

We have formed a technical system that integrates gear rolling machine tool manufacturing, gear rolling process research, and gear rolling cutter mold design and manufacturing. We can flexibly choose the structure according to your actual situation: vertical/horizontal drive: servo/hydraulic automation: Can be used with truss type and articulated manipulators. Efficient, precise and energy-saving, providing a complete solution for all types of gear grinding processing

1.1.Multi-stage CNC gear grinding

Fully CNC controlled, the machine can complete gear rolling processing at multiple positions and different parameters on the same workpiece, saving operating procedures.

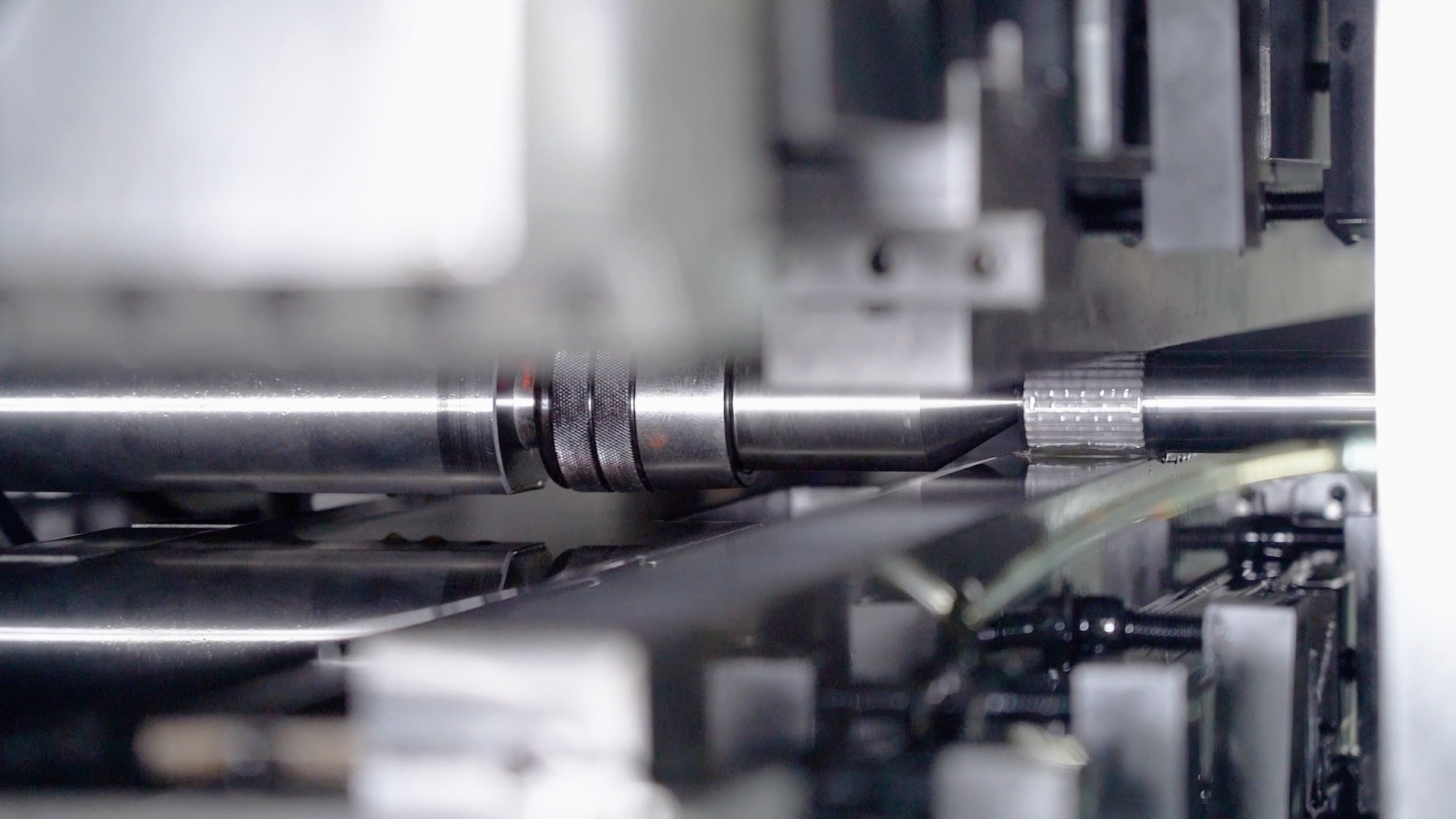

1.2.Servo front and rear top structure

The front and rear tops are directly connected with servo motors, which effectively solves the problem of unstable precision during the gear rubbing process.

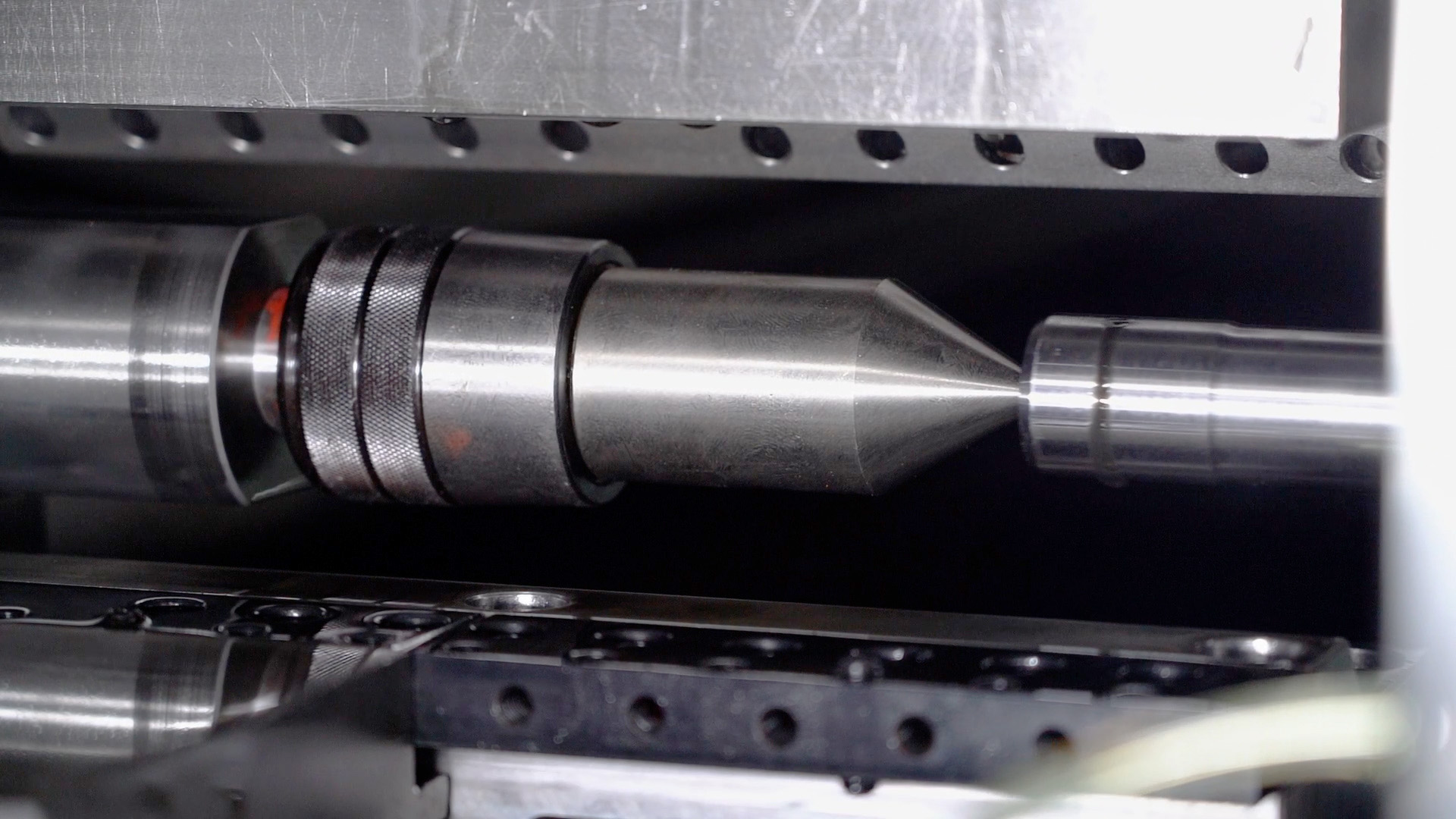

1.3.Dual servo synchronization is more accurate

Dual servo motor drive, more precise synchronization, effective energy saving of more than 70% compared with hydraulic drive, intelligent full servo front and rear jacking technology, effectively solves the problem of clamping.

1.4.High rigidity bed

HT300 cast iron lathe bed, hexahedral frame connected by bolts, stronger overall rigidity, more stable processing.

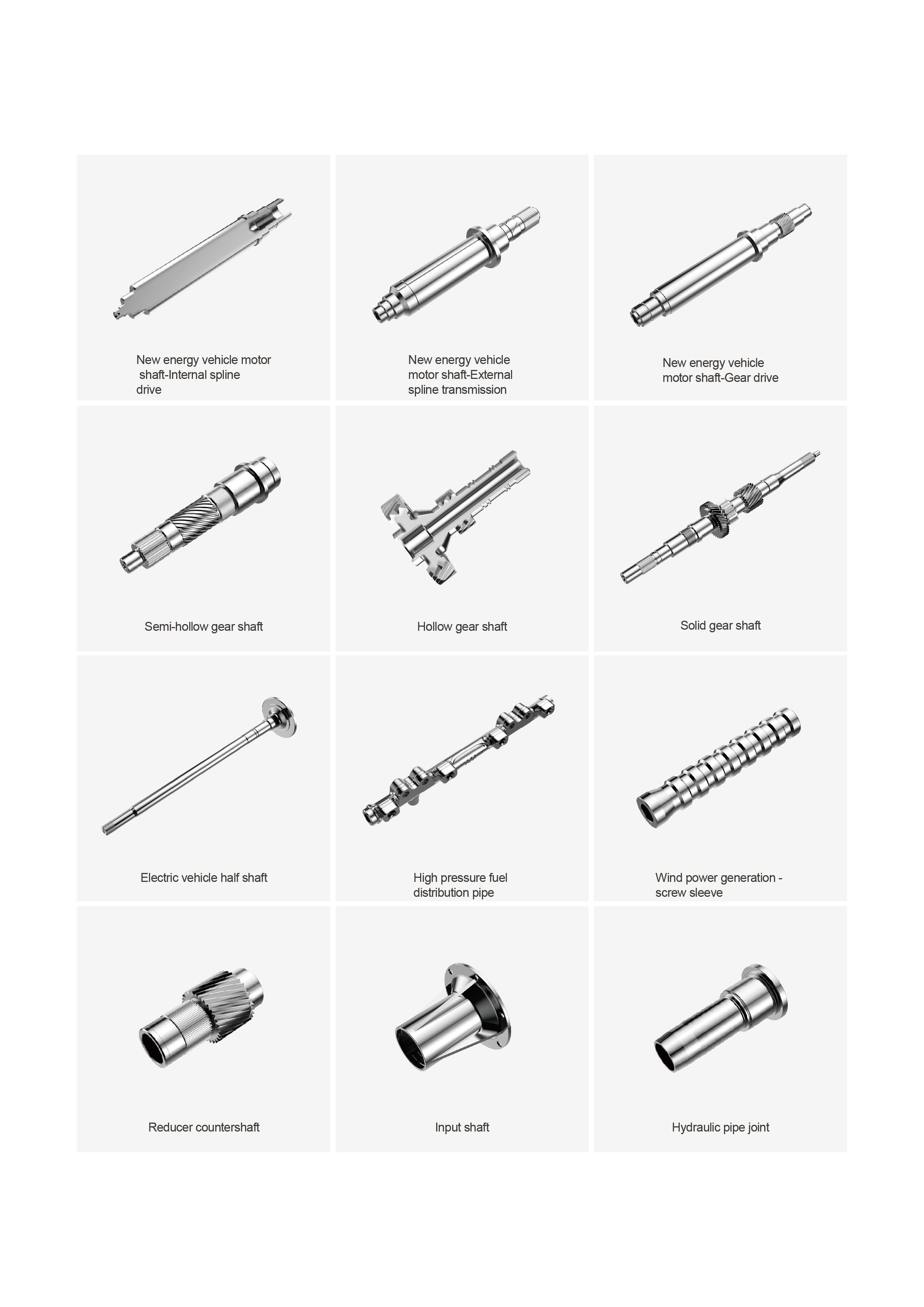

2.Main workpieces of double-end lathe series

3.Technical specications

| Name/Model |

Tool length(inch) |

Max. modulus(m) |

Max. gear diameter(mm) |

Workpiece length (mm) |

Cylindricity(mm) |

Roughness(μm) |

Max. gear length(mm) |

Gear grinding ability coefficient |

| CZL-16MY |

16 |

1.0 |

22 |

800 |

0.01 |

0.4-1.6 |

80 |

35 |

| CZL-24MY |

24 |

1.25 |

40 |

800 |

0.015 |

0.4-1.6 |

100 |

50 |

| CZL-36MY |

36 |

1.75 |

50 |

800 |

0.015 |

0.4-1.6 |

120 |

70 |

| CZL-16NCS |

16 |

1.0 |

22 |

800 |

0.01 |

0.4-1.6 |

60 |

35 |

| CZ-24NCS |

24 |

1.25 |

40 |

800 |

0.015 |

0.4-1.6 |

100 |

50 |

| CZ-36NCS |

36 |

1.75 |

50 |

800 |

0.015 |

0.4-1.6 |

120 |

70 |

| CZ-48NCS |

48 |

2.0 |

60 |

800 |

0.02 |

0.4-1.6 |

150 |

100 |