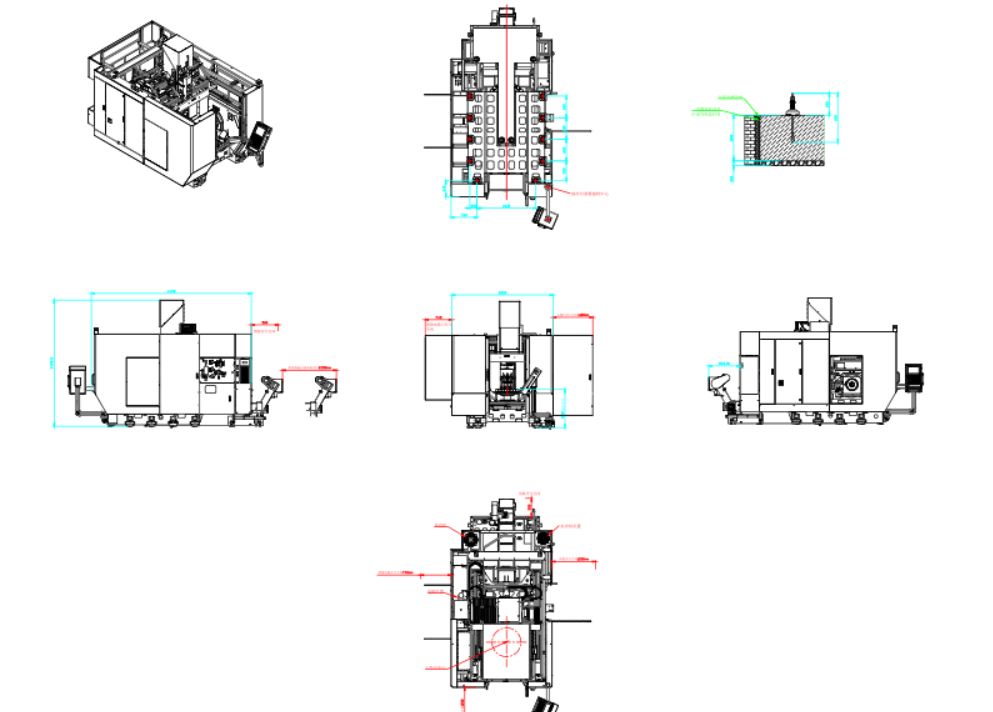

High-speed precision bridge type machining center CBS800

1.Machine Overview

The CBS800 is a high speed, high performance, high precision bridge type 5-axis machining center with high rigidity, high accuracy and high efficiency. The whole machine is designed by finite element analysis to provide the best overall stability performance.

Three axes rapid displacement 48 M/min, T-T tool change time only 4S, tool magazine full load 24 hours tool change without alarm run machine and each machine trial processing sample of 3 times through the element test, to ensure that the machine is efficient and continuous stability after leaving the factory. It is suitable for all kinds of complex shapes of two and three dimensional concave and convex models that require 5-axis linkage for primary processing, and moreover, it is suitable for both small and medium batch multi-species processing production, and also can enter the automatic line for mass production.

The latest TNC640 system from HEIDENHAIN, with 15-inch large LCD display, intelligent warning display and self-diagnosis, makes the machine more convenient to use and maintain; the multi-segment pre-read control is especially suitable for high-speed and large-capacity program processing, and supports network and USB program transfer, which facilitates fast and efficient transmission of large-capacity programs and online processing.

2.Main parameter

|

Item |

Unit |

specification |

|

|

Trevel |

X/Y/Z axis travel |

mm |

800×900×560 |

|

Distance from spindle end to table surface |

mm |

110-670 |

|

|

Maximum distance from spindle center to table surface at 90° of A-axis |

mm |

560 |

|

|

Maximum machining range |

mm |

φ800*560 |

|

|

C-axis turntable

|

Diameter of disc surface |

mm |

Φ650 |

|

Turntable T-slot/guide key width |

mm |

14H7/25H7 |

|

|

Allowable load |

kg |

350 |

|

|

Three-axis feed |

X/Y/Z-axis rapid displacement |

m/min |

48/48/48 |

|

Cutting feed speed |

mm/min |

0-12000 |

|

|

spindle |

Spindle specifications (mounting diameter/transmission method) |

mm |

170/internal concealed |

|

Spindle taper bore |

mm |

A63 |

|

|

Maximum spindle speed |

r/min |

18000 |

|

|

Spindle motor power (continuous/S3 15%) |

kW |

22/26 |

|

|

Spindle motor torque (continuous/S3 15%) |

N.m |

56.8/70 |

|

|

Tool magzine |

Tool magazine capacity |

|

30T |

|

Tool exchange time (T-T) |

s |

4 |

|

|

Max. tool diameter |

mm |

80/120 |

|

|

Max. tool length |

Mm |

300 |

|

|

Max. tool weight |

kg |

8 |

|

|

Guide Rail |

X-axis guideway (size/number of slides) |

mm |

452 |

|

Y-axis guideway (size/number of slides) |

45/2 |

||

|

Z-axis guideway (size/number of slides) |

35/2 |

||

|

Three Axes |

X linear motor thrust (continuous/maximum) |

N |

3866/10438 |

|

Y linear motor thrust (continuous/maximum) |

N |

3866/10438 |

|

|

Z-axis screw |

N |

2R40*20(Double thread) |

|

|

Five axis |

C-axis rated/maximum speed |

rpm |

50/90 |

|

C axis rated/maximum cutting torque |

Nm |

964/1690 |

|

|

A-axis positioning/repetition accuracy |

arc-sec |

10/6 |

|

|

C-axis positioning/repetition accuracy |

arc-sec |

8/4 |

|

|

Three axis accuracy

|

Positioning accuracy |

mm |

0.005/300 |

|

Repeat positioning accuracy |

mm |

0.003/300 |

|

|

Lubrication System

|

Lubrication unit capacity |

L |

0.7 |

|

Lubrication type |

|

Grease lubrication |

|

|

Cutting fluid |

Water tank capacity |

L |

300 |

|

Cutting pump parameters |

|

0.32Mpa×16L/min |

|

|

others |

Air demand |

kg/c㎡ |

≥6 |

|

Air source flow rate |

mm3/min |

≥0.5 |

|

|

Power supply capacity |

KVA |

45 |

|

|

Machine weight (combined) |

t |

17 |

|

|

Dimension (L×W×H) |

mm |

2760×5470×3500 |

|

3.Standard configuration

|

序号 |

Name |

|

1 |

Heidenhaine TNC640 |

|

2 |

Simultaneous tapping function |

|

3 |

X/Y/Z/A/C fully closed loop system |

|

4 |

X/Y/C axis direct drive motor control |

|

5 |

X/Y/C axial temperature control system |

|

6 |

Spindle temperature control system |

|

7 |

Spindle overload protection |

|

8 |

Fully enclosed sheet metal |

|

9 |

Safety door lock system |

|

10 |

Automatic door of tool magazine |

|

11 |

Automatic grease lubrication system |

|

12 |

LED work light illumination |

|

13 |

Mechanical tool setting and tool setting device (Medron) |

|

14 |

Lifting chip conveyor system |

|

15 |

Machining blowing system |

|

16 |

Peripheral spraying system |

|

17 |

Coolant system |

|

18 |

Standard tool and tool box |