High Quality Lathe Machining - 5-axis Machining Center – Oturn

High Quality Lathe Machining - 5-axis Machining Center – Oturn Detail:

Machine Features

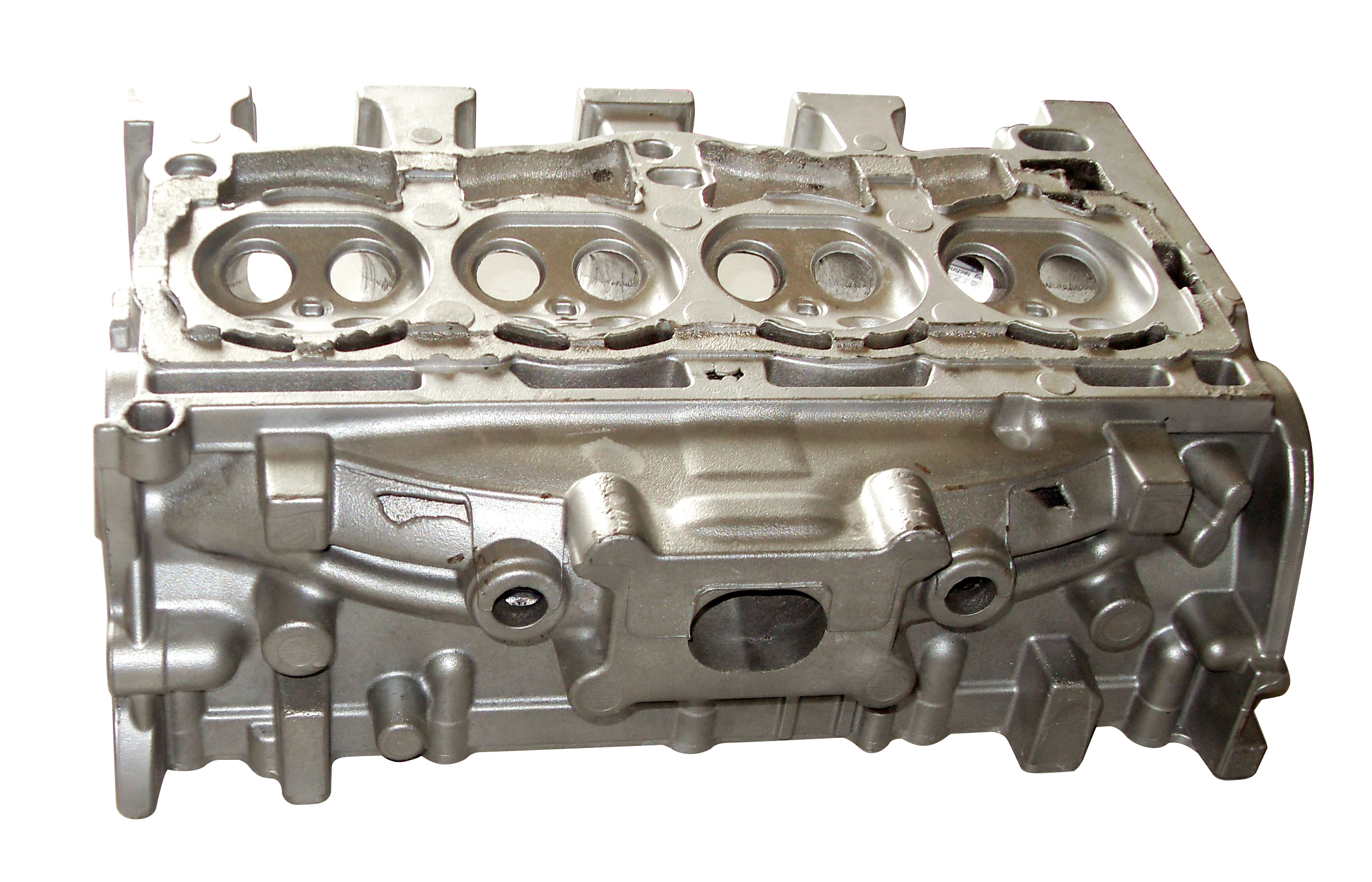

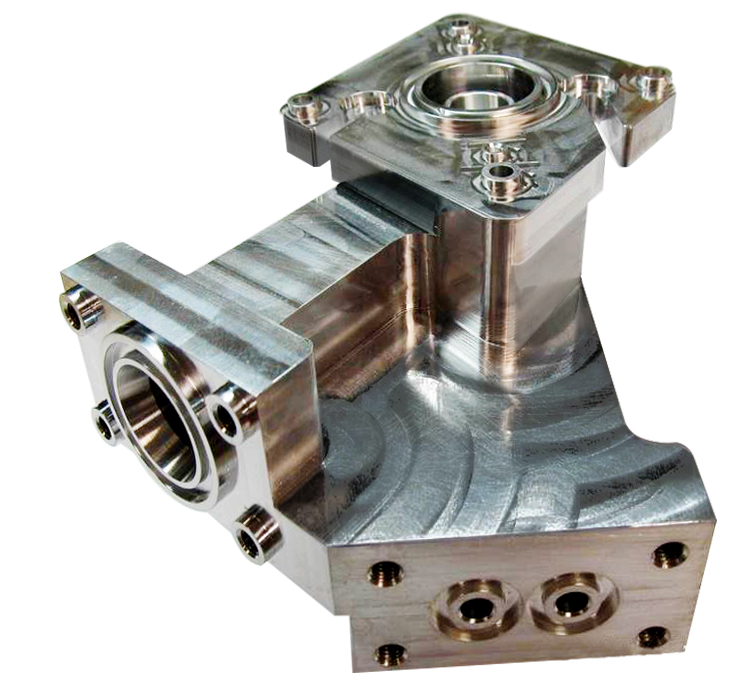

Five-axis simultaneous vertical machining center, which is with stable C-shaped structure, standard high-speed motorized spindle, direct drive CNC turning-table and servo tool library, can achieve high-speed and high-precision processing of complex parts. It is widely used in the manufacture of electric vehicle motors, gearboxes,engines, moulds, robots, medical devices and other products.

Motorized spindle: BT40/HSK A63 speed 12000/1 8000 RPM

Torque 70N.m

BC Axis: Double Direct Drive Turning-Table, Maximum Load 500 kgs

CNC System: Siemens SINUMERIK 840D (Five Axis Linkage) 1

828D (Four Axis Linkage)

Specification

|

Items |

Name |

Specification |

Units |

|

|

Turning-table |

Turning-table diameter |

Φ630 |

mm |

|

|

Max horizontal load |

500 |

Kg |

||

|

Max vertical load |

300 |

|||

|

T-groove (number×width) |

8×14H8 |

Unit×mm |

||

|

B axis swing angle |

-35°~+110° |

° |

||

|

Machining Range |

X-axis Max travel |

600 |

mm |

|

|

Y-axis Max travel |

450 |

mm |

||

|

Z-axis Max travel |

400 |

mm |

||

|

The distance from end face of spindle to working table |

Max |

550 |

mm |

|

|

Min |

150 |

mm |

||

|

Spindle |

Cone hole (7:24) |

BT40 |

||

|

Rated speed |

3000 |

rpm |

||

|

Max speed |

12000 |

|||

|

Output torque of motorized spindle (S1/S6) |

70/95 |

N.m |

||

|

Output power of motorized spindle (S1/S6) |

11/15 |

Kw |

||

|

Axis of coordinates |

Rapid movement |

X-axis |

36 |

m/min |

|

Y-axis |

36 |

|||

|

Z-axis |

36 |

|||

|

Turning-table max speed |

B-axis |

80 |

rpm |

|

|

C-axis |

80 |

|||

|

Feed motor power (X/Y/Z) |

2.3/ 2.3/ 2.3 |

Kw |

||

|

Tool lirary |

Type |

Disc Type |

||

|

Tool selection method |

Two-way proximity selection |

|||

|

Tool libary capacity |

24 |

T |

||

|

Max tool length |

300 |

mm |

||

|

Max tool weight |

8 |

kg |

||

|

Max diameter of tool libary |

Full tool |

Φ80 |

mm |

|

|

Adjacent empty tool |

Φ120 |

mm |

||

|

Tool switch time |

1.8 |

s |

||

|

Tool |

Tool holder |

MAS403 BT40 |

||

|

Pin type |

MAS403 BT40-| |

|||

|

Accuracy |

Execution standard |

GB/T20957.4 (ISO10791-4) |

||

|

Positioning accuracy |

X-axis/Y-axis/Z-axis |

0.010/0.010/0.010 |

mm |

|

|

B-axis/C-axis |

14”/14” |

|||

|

Repeated positioning accuracy |

X-axis/Y-axis/Z-axis |

0.010/0.008/0.008 |

mm |

|

|

B-axis/C-axis |

8”/8” |

|||

|

Weight |

6000 |

kg |

||

|

Capacity |

45 |

KVA |

||

|

Dimensions (Length×Width×Height) |

2400×3500×2850 |

mm |

||

Detail Configurations

BT40/HSKA63 motorized spindle, high precision, high power density, high dynamic response, greatly improve processing efficiency and accuracy, reduce machine noise and vibration.

BC dual-axis direct drive CNC turning-table,built-in motor with large torque,high precision, high dynamic response, greatly improve the performance and application of machine tools.

Hydraulic synchronous tool change technology realizes the coordinated control of servo tool library and servo hydraulic station. The tool switch time can reach1.2s

Equipped with precision high-speed screw, roller guide, to ensure the rigidity and accuracy of machine tools.

The powerful hardware architecture and intelligent control algorithm of SINUMERIK840D sl, assisted by excellent driving and motor technology,enable the processing process to have very high dynamic performance and accuracy

Workpiece

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.