High Quality for Steel Bridge Drill Machine - Single Face Turning Lathe – Oturn

High Quality for Steel Bridge Drill Machine - Single Face Turning Lathe – Oturn Detail:

Machine Features

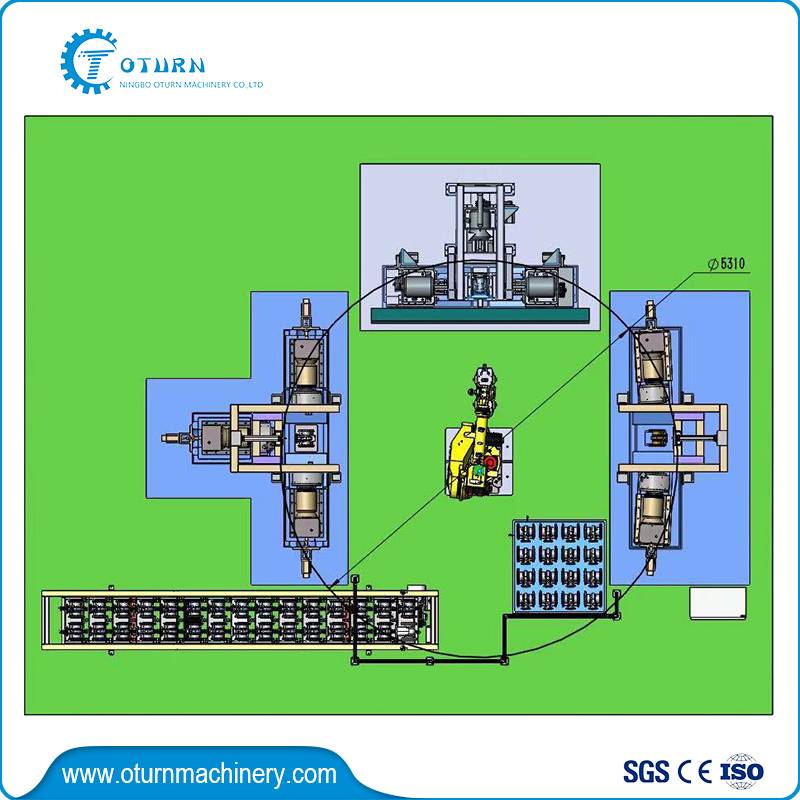

As shown in the figure, the equipment consists of the left bed rail, the power box, the right working table, the CNC rotary table in Taiwan, the hydraulic pressing device and the tooling fixture. The workpiece is positioned in the outer circumference of the contour blank and the hydraulic cylinder is pressed. The left power box is moved by the CNC system to the workpiece under the ball screw drive. The front end of the power box rotates and drives the cutter to perform cutting. Firstly, the main shaft axis of the power box is aligned with one of the calibers. After the outer circle and the groove are finished, the rotary table is rotated by 90° (arbitrary indexing) to process another surface. The worktable is provided with a hydraulic rotary diverter valve, and the clamping cylinder can be rotated with the table and the workpiece.

Tooling structure description: This machine tooling adopts upper and lower automatic centering clamping clamps, which are composed of Taiwan-made synchronous centering cylinders, positioning blocks and clamps. The workpiece is positioned in the outer circle of the shape blank, when the varieties are replaced. Replace the positioning block.

Specification

|

Description |

HDF-BC21-31P |

HDF-BC61-31P |

|

Power supply |

380AC |

380AC |

|

Machine dimensions |

2000*1100*1600mm |

2600*1500*1900mm |

|

CNC Controller system |

GSK/China-English Verison |

GSK/China-English Verison |

|

Main motor power |

4 grade 5.5KW |

4 grade 7.5KW |

|

Spindle speed range(r/min) |

110/140/190 stepless |

110/140/190 stepless |

|

Spindle nose taper hole |

1:20 |

1:20 |

|

The distance from Spindle to worktable |

505mm can be customized according to workpieces |

505mm can be customized according to workpieces |

|

Z-direction feed motor |

28N·m |

28N·m |

|

X-direction feed motor |

8N.m |

8N.m |

|

Z-direction travel |

350mm |

350mm |

|

X-direction travel |

150mm |

150mm |

|

Rapid moving feed(mm/min) |

X-direction:3000 Z-direction:3000 |

X-direction:3000 Z-direction:3000 |

|

Repeat positioning accuracy |

Z direction:0.015/X direction :0.01 |

Z direction:0.015/X direction :0.01 |

|

Max. processing diameter |

430mm |

600mm |

|

Processing time of φ150 workpiece |

About 2min/pc |

About 2min/pc |

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.