Heavy Duty CNC Drilling Milling Machine

CNC Drilling And Milling Machine

High-speed CNC drilling and milling machine

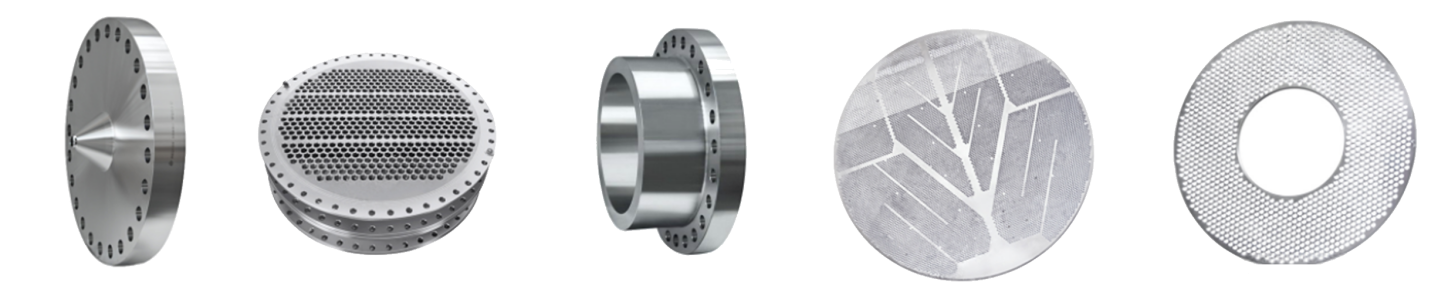

Machine Application

CNC drilling and milling machines are mainly used for efficient drilling of workpieces with thicknesses within the effective range such as plates, flanges, disks and rings. Through-holes and blind holes can be drilled on different kinds of materials. The machine is digitally controlled with easy operation. It can achieve automation, high precision, multiple varieties, mass production.

In order to meet the processing needs of different users, our company has developed a variety of machines. In addition to conventional models, it can also be customized according to the actual needs of customers.

Machine Structure

This equipment is mainly composed of bed table, moving gantry, moving sliding saddle, drilling and milling spindle,automatic lubrication device and protective device, circulating cooling device, CNC control system, electrical system and so on. The supporting and guiding of the rolling line guide and the precision lead screw drive, the machine has high positioning accuracy and repeated positioning accuracy.

1)Worktable:

The working table adopts a casting structure, and the plane has a T-slot with a reasonable finishing layout for clamping workpieces. Above the bed, T-slots are arranged. The drive system uses AC servo motor and precision ball screw to drive on both sides to make the gantry move in the Y-axis direction. Adjustable bolts are distributed on the bottom of the bed, which can easily adjust the level of the bed table.

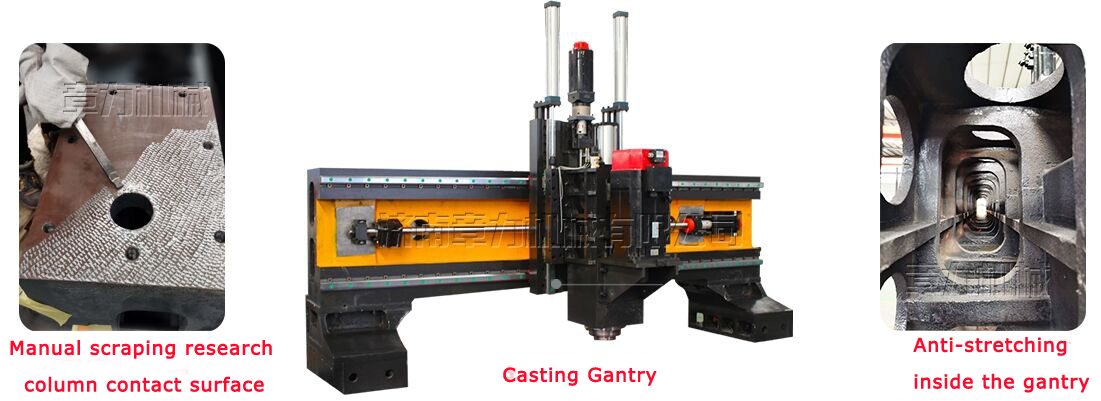

2)Moving gantry:

The mobile gantry is cast with gray iron 250, and two super-high-capacity rolling linear guide pairs are installed on the front side of the gantry. A set of precision ball screw pair and a servo motor make the power head slide move in the X-axis direction. A drilling power head is installed on the power head slide. The movement of the gantry is realized by the servo motor driving the ball wire on the ball screw through the precision coupling.

3)Moving sliding saddle:

The mobile sliding saddle is a precision cast iron structural component. Two ultra-high-capacity NC rail slides and a set of precision ball screw pairs and a high-precision planetary reducer are connected to the servo motor to drive the drilling power head. Moving in the Z-axis direction can realize fast forward, work forward, fast rewind, and stop of the power head. With automatic chip breaking, chip removal, pause functions.

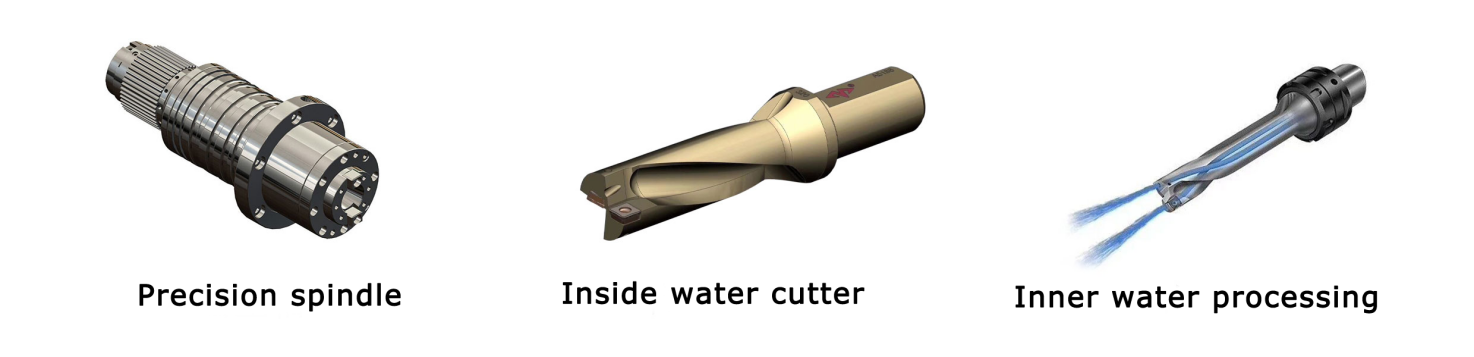

4)Drilling power head(Spindle):

The drilling power head uses a dedicated servo spindle motor, which drives a dedicated precision spindle by decelerating the toothed synchronous belt to increase torque. The spindle uses front three, two, and five-row Japanese angular contact bearings to achieve stepless speed change. Quick and easy replacement, the feed is driven by servo motor and ball screw. The X and Y axes can be linked, and semi-closed loop control is used to achieve linear and circular interpolation functions.

Spindle end is BT40 tapered hole, equipped with Rotorfoss high-speed rotary joint from Italy, which can use high-speed U drill (violent drill) and core drill bit to discharge water.The spindle center water outlet function can improve the cutting efficiency, realize deep hole processing and protect the tool to reduce the use cost.

5)Automatic lubrication device and protection device:

such as guide rails, lead screws, racks, etc., without dead corners to ensure the service life of the machine tool. The X-axis and Y-axis of the machine tool are equipped with dust-proof protective covers, and waterproof splash guards are installed around the workbench.

6)CNC Control System:

6.1With chip breaking function, chip breaking time and chip breaking cycle can be set on the man-machine interface.

6.2With the tool lifting function, the tool lifting height can be set on the man-machine interface. When drilling to this height, the drill bit is quickly raised to the top of the workpiece, and then the chip is thrown, and then fast-forwarded to the drilling surface and automatically converted to the work.

6.3The centralized operation control box and hand-held unit adopt numerical control system, and are equipped with USB interface and LCD liquid crystal display. In order to facilitate programming, storage, display and communication, the operation interface has functions such as man-machine dialogue, error compensation, and automatic alarm.

6.4The machine has the function of previewing and rechecking the hole position before processing, and the operation is very convenient.

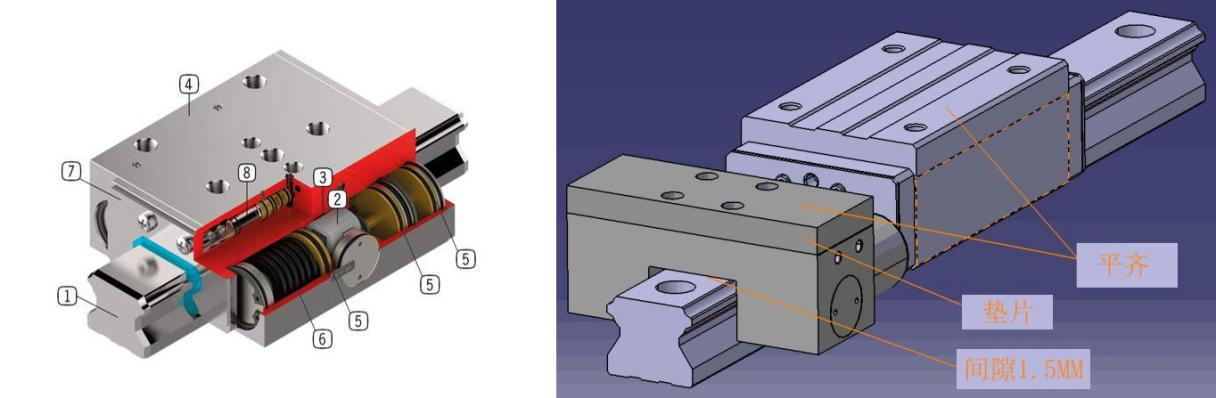

7) Rail clamp

The clamp is composed of a clamp body and an actuator. It is a high-performance functional component used with the rolling linear guide pair. It generates a strong clamping force through the wedge-shaped block expansion principle. Features that increase stiffness.

Features:

- Safe and reliable, strong clamping force, clamping non-moving XY axis during drilling and tapping processing.

- Extremely high clamping force, increase the rigidity of the axial feed, and prevent the micro movement caused by vibration.

- Quick response, opening and closing response time is only 0.06 seconds, which protects the machine tool and improves the life of the screw.

- Durable, nickel-plated surface, good anti-rust performance.

Novel design to avoid rigid impact when clamping.

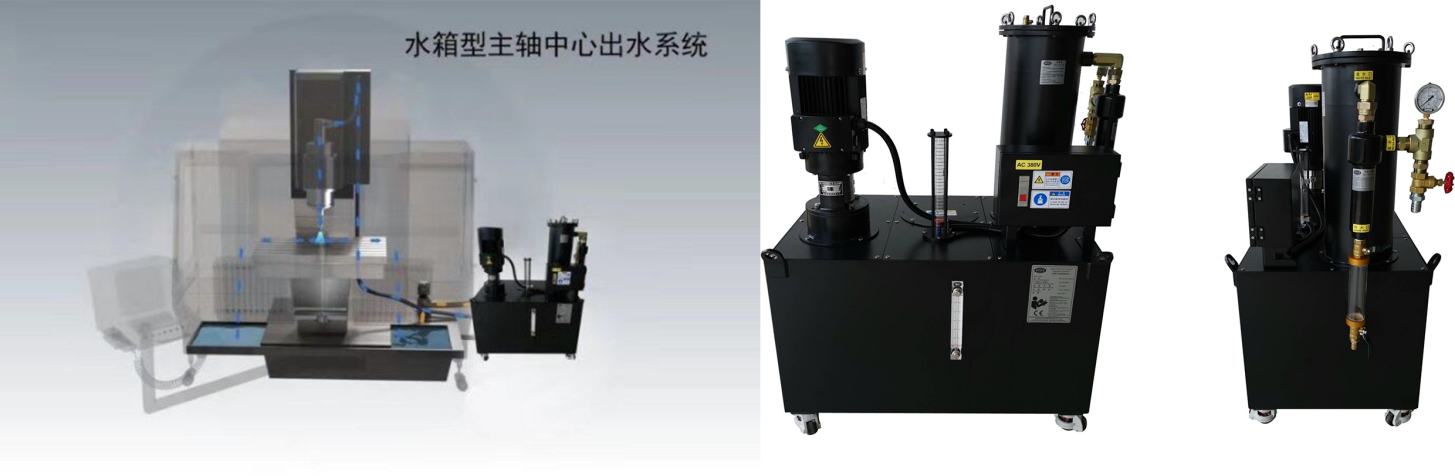

8)Automatic chip remover and circulating cooling device:

An automatic chip remover is arranged at the back of the workbench and a filter is arranged at the end. The automatic chip remover is a flat chain type, and a cooling pump is installed on one side. The outlet of the chip is connected to the central water filtration system. The coolant flows into the chip ejector. The chip ejector lift pump drives the coolant into the central water filtration system. The high-pressure cooling pump circulates the filtered coolant for cutting and cooling. And it is equipped with a chip transporting trolley, which is very convenient to transport iron chips. This equipment is equipped with internal and external cooling system for cutters. When drilling at high speed, the cutters are cooled by internal water and externally during light milling.

Low water alarm

1) When the coolant in the filter is at the middle liquid level, the system automatically connects the motor to start, and the coolant in the chip remover automatically flows into the filter. When the high liquid level is reached, the motor automatically stops working.

2) When the coolant in the filter is at a low level, the system will automatically prompt the liquid level gauge to alarm, the spindle will automatically retract the tool, and the machine will suspend work.

9)Central Outlet Filtration System:

The machine is equipped with a central water filtration system as standard, which can effectively filter the impurities in the coolant. The internal spray water system can prevent iron pins from tangling on the tool during processing, reducing tool wear, extending tool life, improving workpiece surface finish, The high-pressure water outlet pin of the blade tip can well protect the surface of the workpiece, protect the high-speed rotary joint, prevent impurities from blocking the rotary joint, and improve the overall quality of the workpiece and work efficiency.

10) Ball screw and motor integrated seat:

The motor base is a high concentricity product connecting the ball screw and the motor. The angular contact paired bearing (accuracy grade C5) is integrated to improve the accuracy and ensure zero axial clearance of the ball screw when the motor is forward and reverse. It is especially suitable for high-speed equipment.

Assembly accuracy: the ball screw and the motor are installed into one through the motor base. Reduce the concentricity error of motor shaft and ball screw shaft, control it at plus or minus 0.01mm, and the perpendicularity of end face is 0.01.

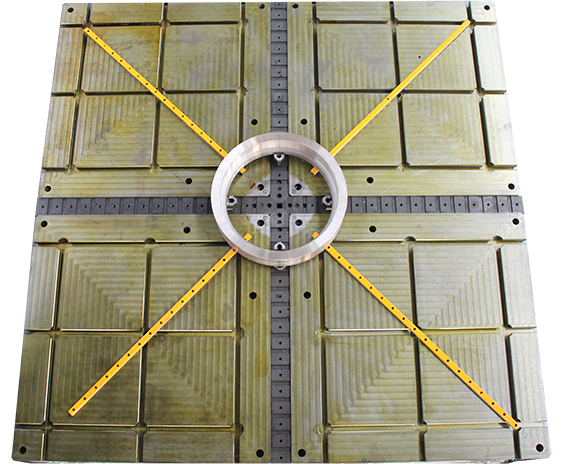

11) Four-claw self-centering table(optional)

The worktable of self-centering equipment is equipped with four-jaw hydraulic self-centering chuck. The workpiece can be centralized automatically in one clamp without each workpiece patrolling to find the center. The clamping is fast and convenient.

Solve the problem that the work piece with indexing circle less than 1600 mm diameter is clamped by pressing plate after feeding and then searching for the center, which consumes less time and takes longer clamping time than processing time.

Self-centering four-jaw chuck independently developed with large jaw stroke makes it difficult for workpiece to touch the jaw when clamping. The strip structure with pad is used.It solves the situation that hydraulic or pneumatic jaws have little travel on the market and large workpieces will impact the jaws when lifting, causing damage to the chucks.

The four jaws on the workbench are in a disassemblable style, and the removal of the rear workbench is a normal platform with its own T-groove.It enhances the application range of other workpieces besides the ring.

Specification

|

Model |

BOSM-DT1010 |

BOSM-DT2010 |

BOSM-DT2016 |

BOSM-DT2525 |

|

|

Working size |

Length*Width (mm) |

1000x1000 |

2000x1000 |

2000x1600 |

2500x2500 |

|

Vertical Drilling Head |

Spindle taper |

BT40/ BT50 |

BT40/ BT50 |

BT40/ BT50 |

BT40/ BT50 |

|

Drilling diameter (mm) |

Φ40/Φ60 |

Φ40/Φ60 |

Φ40/Φ60 |

Φ40/Φ60 |

|

|

Tapping diameter (mm) |

M24 / M36 |

M24 / M36 |

M24 / M36 |

M24 / M36 |

|

|

Spindle speed (r/min) |

30~3000 |

30~3000 |

30~3000 |

30~3000 |

|

|

Spindle power (Kw) |

15/22 |

15/22 |

15/22 |

15/22 |

|

|

Distance from the under end of the spindle to the work surface (mm) |

200~600 / 400~800 |

200~600 / 400~800 |

200~600 / 400~800 |

200~600 / 400~800 |

|

|

Repeat Positioning Accuracy(X/Y/Z) |

X/Y/Z |

±0.01/1000mm |

±0.01/1000mm |

±0.01/1000mm |

±0.01/1000mm |

|

Gross weight (T) |

8.5 |

11 |

13.5 |

16.5 |

|

|

Magazine tool |

Line tool magazine |

||||

Quality Inspection

Each machine of Bosman is calibrated with a laser interferometer from the United Kingdom RENISHAW company, which accurately inspects and compensates for pitch errors, backlash, positioning accuracy, and repeated positioning accuracy to ensure the machine's dynamic, static stability, and processing accuracy. . Ball bar test Each machine uses a ball bar tester from the British RENISHAW company to correct the true circle accuracy and machine geometric accuracy, and perform circular cutting experiments at the same time to ensure the machine's 3D machining accuracy and circle accuracy.

Before&After Service

1)Before Service

Through study the request and necessary information from customers then feedback to our engineers, the Bossman Technical team is responsible for the technical communication with the customers and the formulation of solutions, assisting customer in selecting the appropriate machining solution and suitable machines.

2)After Service

A.The machine with one-year warranty and paid for life-long maintenance.

B.During the one-year warranty period after the machine arrived in destination port, BOSSMAN will provide free and timely maintenance services for various non-man-made faults on machine, and timely replace all kinds of non-man-made damage parts free of charge . Failures occurring out the warranty period shall be repaired at appropriate charges.

C.Technical support in 24 hours online, TM, Skype, E-mail, solving the relative questions in time. if cannot be resolved,BOSSMAN will immediately arrange for after-sales engineer to arrive on-site for repair,buyer need pay for the VISA, flights tickets and accommodation.

Company Site