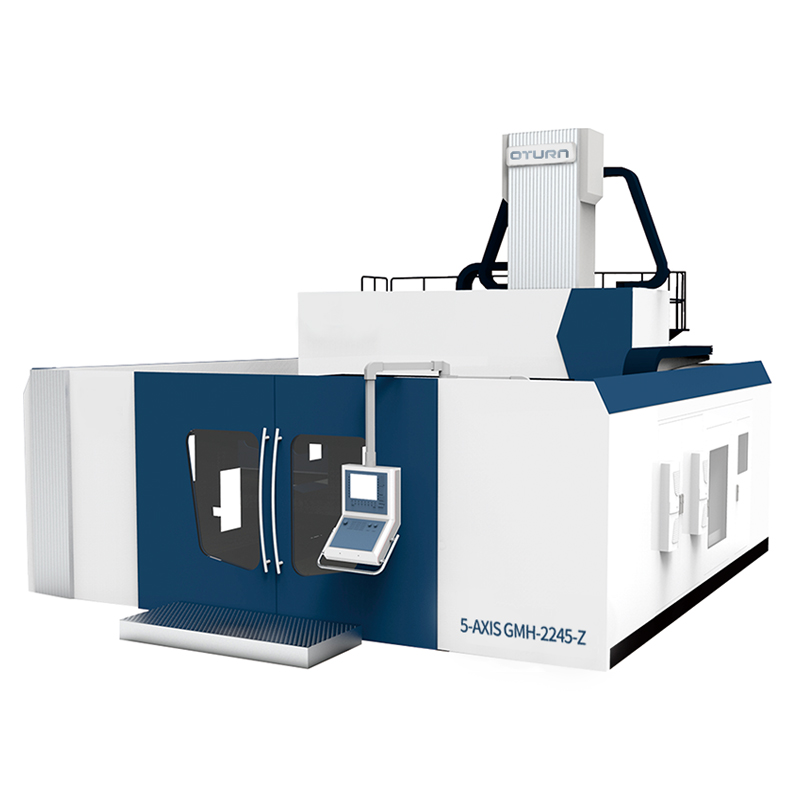

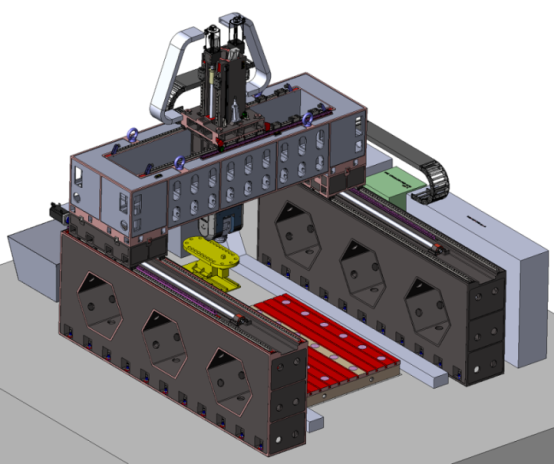

CNC Heavy-duty bridge 5-axis GMH-2245-Z

Introduction of 5-axis machine

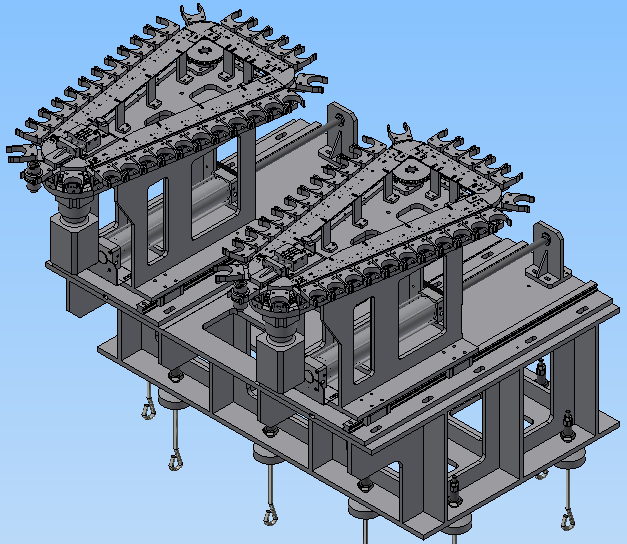

Heavy-duty bridge-type five-axis gantry machining center, the overall layout adopts an elevated bridge-type gantry structure, the overall thermal symmetry and the spindle system box-in-box structure, which solves the problem of the traditional bridge-type high-speed five-axis gantry machining center. The ram adopts the side hanging on the beam to design the spindle The phenomenon of running center can minimize the thermal displacement caused by the change of the ambient temperature in the workshop and improve the machining accuracy of the machine; and this thermally symmetrical design makes the machine less susceptible to harsh environments.

With high-precision five-axis milling head, the main shaft adopts high-speed double swing head, which can realize high-performance milling and high-speed finishing under five-axis linkage, and can realize precise control of machining shape, with high efficiency, high precision, stability and reliability.

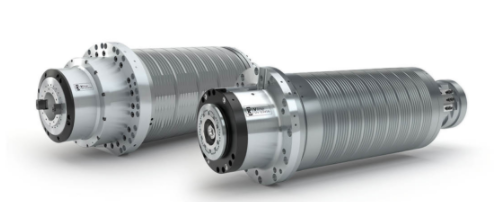

High spindle speed, high precision and good precision retention, grease lubrication, forced circulation cooling.

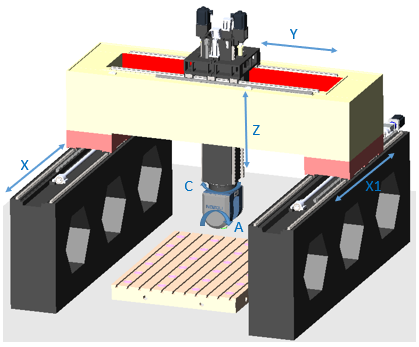

The main axes of the heavy-duty bridge-type five-axis gantry machining center are divided into linear axes X-axis, Y-axis, Z-axis, rotary axis C-axis, A-axis. , the processing of deep drilling, cavity recess and taper on complex surfaces, as well as the problem of efficient and high-quality processing of special-shaped complex parts.

The motion structure is lightweight, reducing the driving load of the ball screw, reducing the wear of the ball screw and linear guide, and correspondingly improving the accuracy;

The viaduct structure also increases the rigidity of the load-bearing part of the machine, which can well avoid the phenomenon of tremors easily occurring when the beam moves rapidly and the spindle moves at high speed;

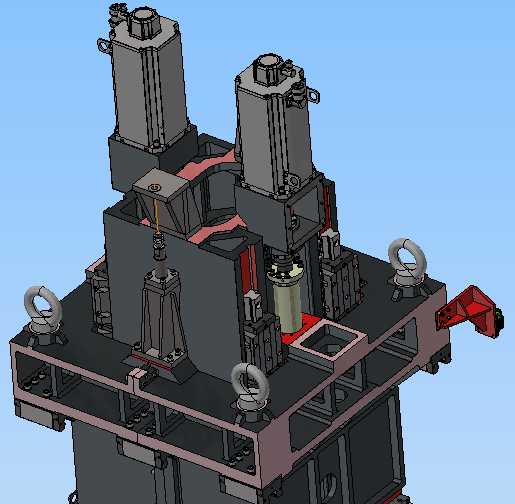

Combined with the double-arm AC five-axis head, the permanent magnet high-torque torque motor mechanism can meet the highest requirements of accuracy, power and dynamic response, remove mechanical transmission components, simple maintenance, high availability, and less structure.

The rotation range of the A-axis is ±110°, and the rotation range of the C-axis is ±270°, which perfectly realizes the vertical and horizontal conversion;

The machining accuracy of the product reaches 5μ; it can process materials such as titanium alloy; the technical level is close to the international leading;

Combined with the fully closed-loop angle encoder with high repeatability, the positioning accuracy of the A and C axes can reach ±5arc sec, and the repeatability of the A and C axis positioning can reach ±3.5arc sec, which not only realizes high-precision machining, but also avoids complex angles. Debug setup.

Double-arm five-axis head

The five-axis gantry machining center can be equipped with three different motorized spindles: high, medium and low. The maximum speed can reach 18000rpm, the spindle power is 35KW, and the maximum torque can reach 118Nm. The tool holder is HSK-A63; the tool is hydraulically supported, and the tool clamping system has a large holding force; the long tool has water from the center of the spindle to cool the machining point, which further improves the machining accuracy; the cutting force is large, the cutting efficiency is high, the processing time is short, and the production energy efficiency is good , basically covering all market needs!

Double-arm five-axis head fused with permanent magnet high-torque torque motor mechanism;

With high precision angle encoder;

And a highly sensitive passive clamping system mechanism;

The five-axis head with a solid and stable overall fork structure design has a compact structure, good rigidity and excellent flexibility;

It perfectly solves the multiple debugging and clamping required for repositioning the workpiece at complex angles, and reduces the positioning error. It is suitable for products with complex parts shape and high precision requirements. It can complete the processing of curved surfaces at various angles in one clamping and improve production efficiency. Personalized configuration, high-precision modular design, to achieve rich expansion functions.

In order to improve the performance of the double-arm AC five-axis head and make it work more scientifically and flexibly, a compact design, high-sensitivity passive clamping system is adopted. The passive qigong clamp with large working force has a safety guarantee function. Once the working air pressure is lost for any reason, it will enter the clamp lock state, which avoids the problem of machine failure and collision during processing, and can better protect the equipment and avoid unnecessary losses. , and the overall system cost is lower. The AC axis has high stability, the clamping force of the A axis can reach 1680Nm, and the clamping force of the C axis can reach 2040Nm, which perfectly realizes high-precision machining.

The heavy-duty bridge-type five-axis gantry machine includes: the worktable, the column, the beam, the sliding seat, the saddle, and the ram are castings to ensure sufficient processing rigidity. For high cutting speed, good cutting condition, high metal removal rate, small stress generated by workpiece cutting, and good workpiece surface quality;

Fast moving speed, less auxiliary time required, equipped with double-arm five-axis head, one-time clamping, multi-angle processing, curved surface processing, streamlined processing.

The whole machine is surrounded by protection, the machine has automatic chip removal function, and is equipped with water cooling function. The machine has beautiful appearance, convenient operation and maintenance.

X-axis

X-axis guide rail form: The column is equipped with four 55mm heavy-duty roller linear guide rails. It can meet the high rigidity and strength requirements of the gantry frame, and can also meet the technical advantages of small friction coefficient, fast moving speed and long service life; lubrication method: grease lubrication; line rail brand: German INA or similar brands;

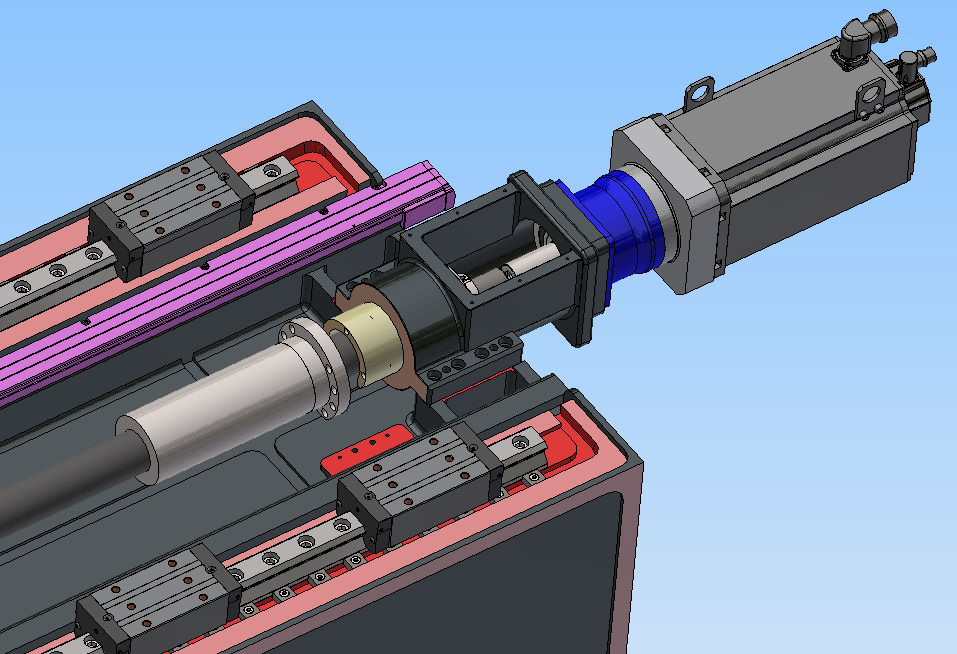

X-axis transmission: After the AC servo motor is decelerated, it drives the 63mm diameter precision ball screw to rotate to realize the front and rear feed of the slide; Lubrication method: grease lubrication; Screw brand: Czech KSK or the same grade brand;

Equipped with double high-precision full-closed-loop grating ruler; grating ruler brand: Spain FAGOR or Germany HEIDENHAIN;

Guide rail protection: The leather cavity shield is used for protection to prevent foreign objects from entering and contaminating the guide rail. The shield has beautiful appearance and reasonable structure.

Y-Axis

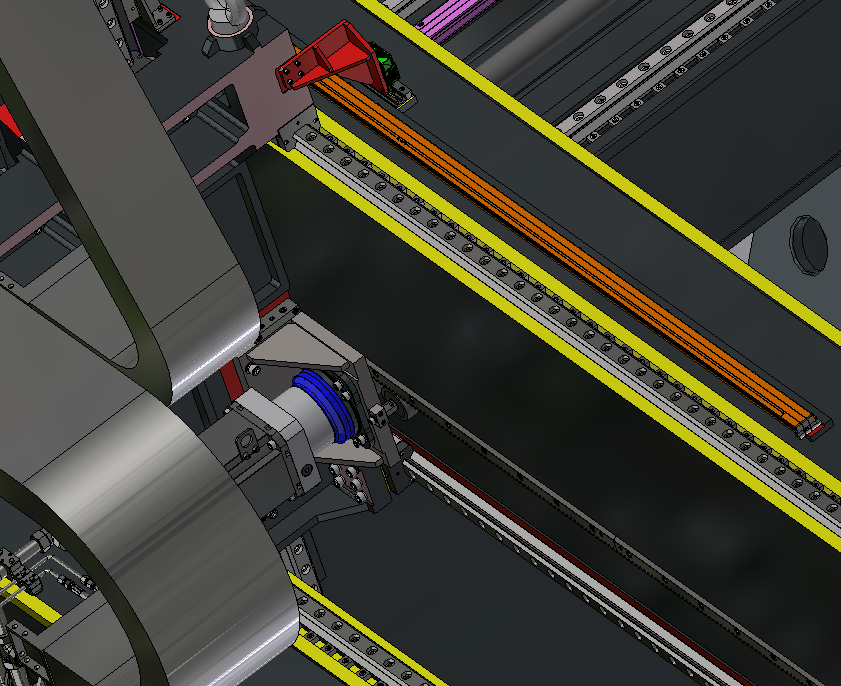

Y-axis guide rail form: the column is equipped with four 55mm heavy-duty roller linear guide rails. It can meet the high rigidity and strength requirements of the gantry frame, and can also meet the technical advantages of small friction coefficient, fast moving speed and long service life; lubrication method: grease lubrication; line rail brand: German INA or similar brands;

Y-axis drive: AC servo motor is used to drive the rack and pinion transmission after deceleration, so as to realize the left and right movement of the saddle; Lubrication method: Grease lubrication; Rack brand: German Alpha or the same grade brand;

Equipped with high-precision full-closed-loop grating scale; grating scale brand: Spain FAGOR or Germany HEIDENHAIN;

Guide rail protection: The leather cavity shield is used for protection to prevent foreign objects from entering and contaminating the guide rail. The shield has beautiful appearance and reasonable structure.

Z-Axis

Z-axis guide rail form: the column is equipped with four 55mm heavy-duty roller linear guide rails. It can meet the Z-axis strength requirements, and can meet the technical advantages of small friction coefficient, fast moving speed and long service life; Lubrication method: grease lubrication; Line rail brand: German INA or similar brands;

Z-axis transmission: AC servo motor is used to drive the precision ball screw with a diameter of 50mm to rotate to realize the up and down lift of the ram; lubrication method: grease lubrication; screw brand: Czech KSK or similar brands, equipped with double nitrogen balance cylinders , balance most of the weight of the moving parts;

Equipped with high-precision full-closed-loop grating scale; grating scale brand: Spain FAGOR or Germany HEIDENHAIN;

Guide rail protection: The leather cavity shield is used for protection to prevent foreign objects from entering and contaminating the guide rail. The shield has beautiful appearance and reasonable structure.

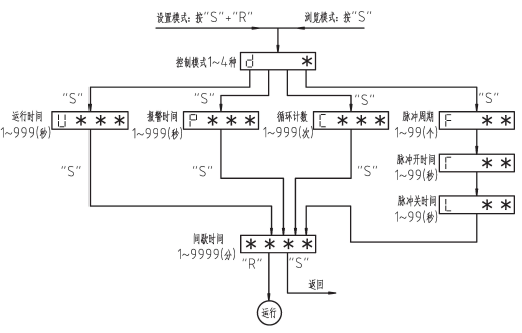

CNC system controller: Heidenhain TNC640

Hydraulic and Lubrication System

Lubrication system; this machine adopts group independent oil supply technology

(1) A set of independent automatic oil supply and lubrication system is adopted for X, Y, Z axis guide rail, lead screw and rack. The screw bearing is grease lubricated. Brand: Nanjing Bechier

Hydraulic system

(1) This machine is equipped with an independent hydraulic system.

(2) The machine is equipped with a separate hydraulic pump station, and the hydraulic system is equipped with a number of safety monitoring devices such as oil level alarm, temperature alarm, backflow blockage alarm, and minimum working pressure alarm to ensure that the machine works under various safe conditions. , improve the safety protection of operators.

(3) Hydraulic station brand: Dezhiyi Hydraulic

Tool magazine

Horizontal tool magazine-two-way forward and reverse arbitrary-32T tool magazine brand: Taiwan-funded enterprise Desu/Okada or similar brands

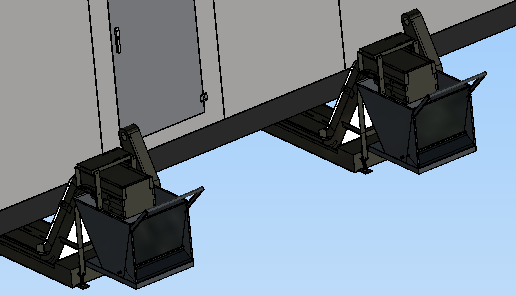

Chip conveyor

Chain plate type chip conveyors are installed on both sides of the worktable, and pits are installed in the foundation, which has good leakage prevention effect;

The chip conveyors on both sides of the processing area quickly transport the iron chips generated by high-speed processing to the lifting chip conveyor, reducing the thermal deformation and deformation of the machine, and ensuring the accuracy and stability of the machine;

Technical Information

|

MODEL |

GMH-2245-Z |

|

Work table size (mm) |

2200*4000 |

|

X-axis travel (mm) |

4500 |

|

Y-axis travel (mm) |

2500 |

|

Z-axis travel (mm) |

1500 |

|

Gantry width (mm) |

3400 |

|

Spindle end face - working table distance (mm) |

150-1150 |

|

Spindle speed (rpm) |

18000 |

|

Spindle holder |

HSK-A63 |

|

C-axis rotation range (°) |

±270° |

|

A-axis rotation range (°) |

±110° |

|

Workbench load (t/m2) |

5 |

|

work feed(m/min) |

20/20/20 |

|

Rapid feed(m/min) |

40/40/40 |

|

Power(kw) |

35(S1)/43.8(S6 40%) |

|

Torque(Nm) |

95(S1)/118(S6 40%) |

|

X/Y/Z positioning accuracy(mm) |

0.030/0.025/0.025 |

|

A/C positioning accuracy(mm) |

±5 |

|

X/Y/Z repeatability(mm) |

0.015/0.010/0.010 |

|

A/C Repeatability(mm) |

±5 |

|

Tool magazine |

32 |

|

CNC system |

HEIDENHAIN TNC640 |

Standard configuration

|

Siemens 840Dsl CNC system |

Germany |

|

X, Y, Z feed servo motors |

HEIDENHAIN Germany |

|

XYZ Servo Drive |

HEIDENHAIN Germany |

|

AC Servo Spindle Motor |

HEIDENHAIN Germany |

|

Five-axis five-link head |

Shanghai |

|

Ball screw |

HIWIN or equivalent brand |

|

Linear Roller Guide |

HIWIN or equivalent brand |

|

Each shaft screw bearing |

Japan NSK or equivalent brand |

|

Coupling |

Taiwan or equivalent brand |

|

Spiral cutter |

Shanghai |

|

machine guide rail protection |

Shanghai |

|

Oil pump and centralized lubrication system |

Proton or SKF or equivalent |

|

Proximity switch, intermediate relay |

Omron/Schneider or equivalent |

|

hand pulse generator |

System supplier designated manufacturer/or equivalent brand |

|

Spindle |

INNA or equivalent |

|

machine large casting |

Shanghai |

|

machine sheet metal outer protection |

Shanghai |

|

machine anchor bolts, horn complete set |

Shanghai |

|

Hydraulic system |

famous in China |

|

Work Lights and Warning Lights |

famous in China |

|

Spindle ram balance mechanism |

famous in China |

|

Spindle cooling system and water supply system |

famous in China |

|

Common maintenance tools |

famous in China |

|

Mechanical Instruction Manual |

|

|

Electrical Instruction Manual |

|

|

Certification |

|

|

Packing List |

|

|

Electrical schematic |

|

|

System Operation Manual |

|

|

System Maintenance Manual |

|

|

System parameter manual |

|

|

System factory parameter table |

|

|

Foundation drawing |

Provided after the contract takes effect |

|

Control box temperature regulator manual |

|

Thanks for your attention!