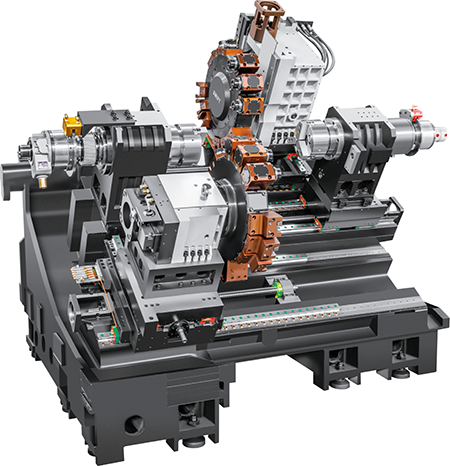

Hard Rail Turning Center TMC Series

Product Configuration

Features

High rigidity, heavy cutting, high stability:

It adopts an integral cast inclined bed and 30° inclined guide rails, making it easy for the operator to get on and off the workpiece, and the cutting arrangement is smooth.It is designed with thick reinforcement ribs to minimize distortion and thermal deformation.

High precision and high dynamic response:

Using two pairs of high-precision NSK P4 bearings, the spindle achieves high rigidity and extremely high spindle rotation accuracy. The spindle achieves stepless speed regulation through an AC servo motor.

Thermal stability:

The main spindle box and the sliding saddle are on the same angular plane, which reduces distortion caused by thermal deformation of the main spindle box.

Using high-speed rolling bearings and quantitative grease sealing lubrication to ensure the thermal stability of the body and spindle temperatures.

Technical Specifications

|

Item |

860TMC/1000(H) |

860TMC/1500(H) |

860TMC/2000(H) |

|

|

Bed |

The bed and base are made of high-quality cast iron, and the bed is slanted at 30°. |

|||

|

Processing range |

Maximum rotation diameter of bed |

Φ880mm |

Φ880mm |

Φ880mm |

|

Maximum processing diameter of discs |

Φ600mm |

Φ600mm |

Φ600mm |

|

|

Maximum processing diameter of the carriage |

Φ600mm |

Φ600mm |

Φ600mm |

|

|

Maximum processing length of bar |

950mm |

1550mm |

2100mm |

|

|

Maximum bar hole diameter |

Φ75 |

Φ75 |

Φ75 |

|

|

Travel Feed |

X-axis maximum travel |

330mm |

330mm |

330mm |

|

Y-axis maximum travel |

150/box way |

150/box way |

150/box way |

|

|

Z-axis maximum travel |

1200mm |

1800mm |

2400mm |

|

|

X/Z axis rapid movement rate |

16m/min |

16m/min |

16m/min |

|

|

X/Z screw diameter/pitch |

X:40/08 Z:50/10 |

X:40/08 Z:50/10 |

X:40/08 Z:50/10 |

|

|

X/Z axis slide way specifications |

Square slide way |

Square slide way |

Square slide way |

|

|

X-axis servo motor |

α22(with brake) |

α22(with brake) |

α22(with brake) |

|

|

Y-axis servo motor |

α12(with brake) |

α12(with brake) |

α12(with brake) |

|

|

Z-axis servo motor |

α22 |

α22 |

α30 |

|

|

Turret servo motor |

1KW |

1KW |

1KW |

|

|

Power head motor |

α22 |

α22 |

α22 |

|

|

Precision |

X/Z axis positioning accuracy |

±0.005/300mm |

±0.005/300mm |

±0.005/300mm |

|

X/Z axis repeat accuracy |

±0.005/300mm |

±0.005/300mm |

±0.005/300mm |

|

|

Tailstock |

Tailstock sleeve specifications |

Mohs5#/1050mm |

Mohs5#/1600mm |

Mohs5#/2100mm |

|

Tailstock sleeve diameter/travel |

Φ100/80 |

Φ100/80 |

Φ100/80 |

|

|

Tailstock pressure range |

5-30Kg/cm² |

5~30Kg/cm² |

5~30Kg/cm² |

|

|

Tailstock moving method |

Manual latch (driven by saddle) |

Manual latch (driven by saddle) |

Manual latch (driven by saddle) |

|

|

Spindle |

Spindle nose type |

A2-8 |

A2-8 |

A2-8 |

|

Spindle through hole diameter |

Φ87 |

Φ87 |

Φ87 |

|

|

Spindle maximum speed |

2500rpm |

2500rpm |

2500rpm |

|

|

Spindle servo motor power |

22kw |

22kw |

30kw |

|

|

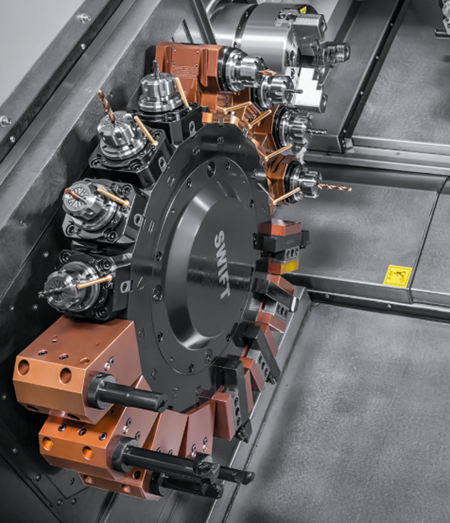

Turret |

Servo powered turret |

BMT65/12 workstations |

BMT65/12 workstations |

BMT65/12 workstations |

|

Tool cutter specifications |

380 |

380 |

380 |

|

|

Tool holder specifications |

□25*25Φ40 |

□25*25Φ40 |

□25*25Φ40 |

|

|

0 degree side milling head (1 piece) |

ER40/4000rpm |

ER40/4000rpm |

ER40/4000rpm |

|

|

90 degree side milling head (1 piece) |

ER40/4000rpm |

ER40/4000rpm |

ER40/4000rpm |

|

|

Other |

Total capacitance |

48KW |

48KW |

57KW |

|

Machine net weight |

About 6500kg |

About 7000kg |

About 8000kg |

|

|

Machine size (length*width*height) |

5100*2300*2450 |

6000*2500*2350 |

6500*2500*2350 |

|

Configuration Features

Spindle

Support high-precision and heavy-duty cutting to increase productivity.

Turret

Improves indexing reliability and ensures high rigidity.

System

Standard FANUC F Oi-TF Plus CNC System, high processing performance high operating rate, high ease of use.

High Rigidity

Heavy-duty Cast Iron Base And Components, Strong shock absorption and high stability.

ELECTRICAL BOX

Store electrical components of the lathe to protect them, with good heat dissipation.

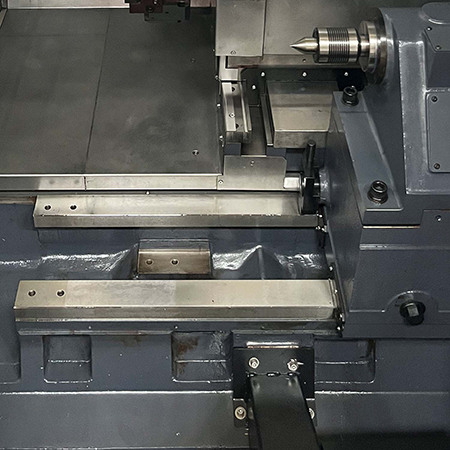

HARD RAIL

Hard rail has high friction, inertia, andstrengthGood rigidity and strong load-bearing capacity.