Hard rail Single Spindle 250L series

Product Configuration

Introduce

Large hard rail type high load machine, with large diameter low speed heavy cutting processing capability.

High rigidity square rail, the slide surface is designed with professional scraping program and precision oil guide groove, and the transmission efficiency is excellent.

The machine body has a 30-degree inclined back integrated box structure, low center of gravity, and stable precision.

The tailstock body has strong rigidity and good vibration suppression.

The Z-axis saddle can be driven by program, and the tailstock displacement is automatically controlled by the program.

Technical Specifications

|

Item |

Name |

Unit |

250L10 |

250LM10 |

250L15 |

250LM15 |

|

Travel |

Max. upper rotation of the bed |

mm |

Φ860 |

Φ860 |

Φ860 |

Φ860 |

|

Max. processing diameter |

mm |

Φ570 |

Φ550 |

Φ570 |

Φ550 |

|

|

Max. processing diameter on the tool holder |

mm |

Φ570 |

Φ550 |

Φ570 |

Φ550 |

|

|

Max. processing length |

mm |

930 |

900 |

1460 |

1460 |

|

|

Spindle Cylinder Chuck |

Spindle nose |

type |

A2-8 |

A2-8 |

A2-11 |

A2-11 |

|

Max. spindle speed |

rpm |

3200 |

3200 |

2500 |

2500 |

|

|

Cylinder/chuck |

lnch |

10″ |

10″ |

12″ |

12″ |

|

|

Spindle aperture |

mm |

Φ86 |

Φ86 |

Φ102 |

Φ102 |

|

|

Bar diameter |

mm |

Φ76 |

Φ76 |

Φ90 |

Φ90 |

|

|

Spindle motor power |

kw |

15/18.5 |

15/18.5 |

15/18.5 |

15/18.5 |

|

|

Motor torque |

Nm |

286/472 |

286/472 |

358/590 |

358/590 |

|

|

X/Z feed section Parameters |

X/Z axis limit travel |

mm |

300/980 |

280/965 |

300/1550 |

300/1560 |

|

X/Z axis guide rail width |

/ |

Hard rail 80 |

Hard rail 80 |

Hard rail 80 |

Hard rail 80 |

|

|

X/Z axis motor torque |

Nm |

22 |

22 |

22 |

22 |

|

|

X/Z axis motor power |

kw |

3.0 |

3.0 |

3.0 |

3.0 |

|

|

Positioning accuracy |

mm |

±0.005 |

±0.005 |

±0.005 |

±0.005 |

|

|

Repeat positioning accuracy |

mm |

±0.003 |

±0.003 |

±0.003 |

±0.003 |

|

|

X/Z axis rapid movement |

m/min |

20/20 |

20/20 |

20/20 |

20/20 |

|

|

Servo drive Cutter/ Servo Cutter |

Power turret type |

BMT65-12T |

BMT65-12 |

|||

|

Power turret power |

5.5/7.5 |

5 |

||||

|

Max. speed of power tool holder |

6000 |

5000 |

||||

|

Outer diameter tool holder specifications |

mm |

32X32 |

25X25 |

32X32 |

25X25 |

|

|

Inner diameter tool holder specifications |

mm |

Ф50 |

Φ50 |

Ф50 |

Φ50 |

|

|

Adjacent tool change time |

sec |

0.2 |

0.2 |

0.2 |

0.38 |

|

|

Tail stock |

Hydraulic tailstock |

/ |

Hydraulic tailstock |

Hydraulic tailstock |

Hydraulic tailstock |

Hydraulic |

|

Tailstock Max. travel |

mm |

700 |

680 |

1250 |

1240 |

|

|

Tailstock sleeve taper hole |

type |

Mohs 5# |

Morse 5# |

Mohs 5# |

Mohs 5# |

|

|

Tailstock sleeve diameter |

mm |

Ф100 |

Ф100 |

Ф100 |

Ф100 |

|

|

Sleeve travel |

mm |

80 |

80 |

80 |

80 |

|

|

Mechanical Size |

Overall dimensions (length x width x height) |

mm |

4185*2300*2355 |

4185*2300*2355 |

4800*2300*2355 |

4800*2300*2355 |

|

Weight (approximate weight) |

kg |

6800 |

6800 |

7300 |

7500 |

|

|

Other |

Cutting fluid tank volume |

L |

270 |

270 |

320 |

320 |

|

Hydraulic unit box volume |

L |

40 |

40 |

40 |

0.75 |

|

|

Cutting water pump |

kw |

0.75 |

1.5 |

40 |

||

|

Hydraulic oil pump motor power |

kw |

1.5 |

1.5 |

1.5 |

||

|

Lubricating oil tank volume |

L |

2 |

2 |

2 |

2 |

|

|

Automatic lubrication pump motor power |

W |

50 |

50 |

50 |

50 |

|

|

Cooling water pump power |

W |

750 |

750 |

750 |

750 |

|

Item |

Name |

Unit |

250L20 |

250LM20 |

250L30 |

250LM30 |

|

Travel |

Max. upper rotation of the bed |

mm |

Φ840 |

Φ840 |

Φ820 |

Φ820 |

|

Max. processing diameter |

mm |

Φ570 |

Φ550 |

Φ570 |

Φ550 |

|

|

Max. processing diameter on the tool holder |

mm |

Φ570 |

Φ550 |

Φ570 |

Φ550 |

|

|

Max. processing length |

mm |

2090 |

2050 |

3200 |

3200 |

|

|

Spindle Cylinder Chuck |

Spindle nose |

type |

A2-11 |

A2-11 |

A2-15 |

A2-15 |

|

Max. spindle speed |

rpm |

2500 |

2500 |

1500 |

1500 |

|

|

Cylinder/chuck |

lnch |

12″ |

12″ |

15″ |

15″ |

|

|

Spindle aperture |

mm |

Φ102 |

Φ102 |

Φ132 |

Φ132 |

|

|

Bar diameter |

mm |

Φ90 |

Φ90 |

Φ117 |

Φ117 |

|

|

Spindle motor power |

kw |

15/18.5 |

15/18.5 |

15/18.5 |

15/18.5 |

|

|

Motor torque |

Nm |

358/590 |

358/590 |

550/680 |

550/680 |

|

|

X/Z feed section Parameters |

X/Z axis limit travel |

mm |

305/2100 |

320/2170 |

305/3300 |

320/3300 |

|

X/Z axis guide rail width |

spes |

Hard rail 80 |

Hard rail 80 |

Hard rail 80 |

Hard rail 80 |

|

|

X/Z axis motor torque |

Nm |

22 |

22 |

22 |

22 |

|

|

X/Z axis motor power |

kw |

3.0 |

3.0 |

3.0 |

3.0 |

|

|

Positioning accuracy |

mm |

±0.005 |

±0.005 |

±0.005 |

±0.005 |

|

|

Repeat positioning accuracy |

mm |

±0.003 |

±0.003 |

±0.003 |

±0.003 |

|

|

X/Z axis fast movement |

m/min |

18/18 |

18/18 |

18/18 |

18/18 |

|

|

Servo drive Cutter |

Power turret type |

pcs |

BMT65 |

BMT65-12 |

||

|

Power turret power |

KW |

5.0 |

5.0 |

|||

|

Max. speed of power tool holder |

rpm |

5000 |

5000 |

|||

|

Outer diameter tool holder specifications |

mm |

32X32 |

25X25 |

32X32 |

25X25 |

|

|

Inner diameter tool holder specifications |

mm |

Ф50 |

Φ50 |

Ф50 |

Φ50 |

|

|

Adjacent tool change time |

sec |

0.2 |

0.2 |

0.15 |

0.2 |

|

|

Tail stock |

Hydraulic tailstock |

/ |

Hydraulic |

Hydraulic tailstock |

Hydraulic tailstock |

Hydraulic tailstock |

|

Max. tailstock travel |

mm |

1840 |

1840 |

3000 |

2980 |

|

|

Tailstock sleeve taper hole |

type |

Mohs 5# |

Mohs 5# |

Mohs 5# |

Mohs 5# |

|

|

Tailstock sleeve diameter |

mm |

Ф100 |

Ф100 |

Ф100 |

Ф100 |

|

|

Sleeve travel |

mm |

80 |

80 |

80 |

80 |

|

|

Mechanical Size |

Overall dimensions (length x width x height) approx. |

mm |

5450*2300*2355 |

5450*2300*2355 |

6700*2300*2355 |

6700*2300*2355 |

|

Weight (approx. weight) |

kg |

7500 |

7800 |

12300 |

12500 |

|

|

Other |

Cutting fluid tank volume |

L |

370 |

370 |

470 |

470 |

|

Cutting water pump |

kw |

0.75 |

0.75 |

|||

|

Hydraulic unit box volume |

L |

40 |

40 |

40 |

40 |

|

|

Hydraulic oil pump motor power |

kw |

1.5 |

1.5 |

1.5 |

1.5 |

|

|

Lubricating oil tank volume |

L |

2 |

2 |

2 |

2 |

|

|

Automatic lubrication pump motor power |

W |

50 |

50 |

50 |

50 |

|

|

Cooling water pump power |

W |

750 |

750 |

750 |

750 |

|

Item |

Name |

Unit |

250LMY10 |

250LMY15 |

250LMY30 |

|

|

Travel |

Max. upper rotation of the bed |

mm |

Φ860 |

Φ860 |

Φ820 |

|

|

Max. processing diameter |

mm |

Φ540 |

Φ540 |

Φ540 |

||

|

Max. processing diameter on the tool holder |

mm |

Φ540 |

Φ540 |

Φ540 |

||

|

Max. processing length |

mm |

780 |

1340 |

3080 |

||

|

Spindle Cylinder Chuck |

Spindle nose |

type |

A2-8 |

A2-11 |

A2-15 |

|

|

Max. spindle speed |

rpm |

3200 |

2500 |

1500 |

||

|

Cylinder/chuck |

lnch |

10″ |

12″ |

15″ |

||

|

Spindle aperture |

mm |

Φ86 |

Φ102 |

Φ132 |

||

|

Bar diameter |

mm |

Φ76 |

Φ90 |

Φ117 |

||

|

Spindle motor power |

kw |

15/18.5 |

15/18.5 |

15/18.5 |

||

|

Motor torque |

Nm |

286/472 |

358/590 |

550/680 |

||

|

X/Z feed section Parameters |

X/Z/Y axis limit travel |

mm |

310/880/120±60 |

310/1450/120±60 |

318/3180/120±60 |

|

|

X/Z axis guide rail width |

spes |

Hard rail 80 |

Hard rail 80 |

Hard rail 80 |

||

|

Y axis guide rail specification |

/ |

Roller rail 35 |

滚柱线轨35 |

Roller rail 35 |

||

|

X/Z axis motor torque |

Nm |

22/22 |

22 |

22 |

||

|

X/Z/Y axis motor power |

kw |

3.0/3.0/1.8 |

3.0/3.0/1.8 |

3.0/3.0/1.8 |

||

|

Positioning accuracy |

mm |

±0.005 |

±0.005 |

±0.005 |

||

|

Repeat positioning accuracy |

mm |

±0.003 |

±0.003 |

±0.003 |

||

|

X/Z/Y axis fast movement |

m/min |

20/20/8 |

20/20/8 |

18/18/8 |

||

|

Servo drive Cutter |

Power turret type |

pcs |

BMT65-12T |

BMT65-12 |

BMT65-12 |

|

|

Power turret power |

KW |

5.5/7.5 |

5.0 |

5.0 |

||

|

Max. speed of power tool holder |

rpm |

5000 |

5000 |

5000 |

||

|

Outer diameter tool holder specification |

mm |

25X25 |

25X25 |

25X25 |

||

|

Inner diameter tool holder specification |

mm |

Φ50 |

Φ50 |

Φ50 |

||

|

Adjacent tool change time |

sec |

0.38 |

0.38 |

0.2 |

||

|

Tail stock |

Hydraulic tailstock |

/ |

Hydraulic tailstock |

液压 |

Hydraulic tailstock |

|

|

Max. tailstock travel |

mm |

550 |

1100 |

2850 |

||

|

Tailstock sleeve taper hole |

type |

Morse 5# |

Mohs 5# |

Mohs 5# |

||

|

Tailstock sleeve diameter |

mm |

Ф100 |

Ф100 |

Ф100 |

||

|

Sleeve travel |

mm |

80 |

80 |

80 |

||

|

Mechanical Size |

Overall dimensions (length x width x height) |

mm |

4185*2300*2355 |

4800*2300*2355 |

6700*2300*2355 |

|

|

Weight (approximate weight) |

kg |

7200 |

7700 |

12800 |

||

|

Other |

Cutting fluid tank volume |

L |

270 |

320 |

470 |

|

|

Cutting water pump |

kw |

0.75 |

0.75 |

0.75 |

||

|

Hydraulic unit box volume |

L |

40L |

40 |

40L |

||

|

Hydraulic oil pump motor power |

kw |

1.5 |

1.5 |

1.5 |

||

|

Lubricating oil tank volume |

L |

2 |

2 |

2 |

||

|

Automatic lubrication pump motor power |

W |

50 |

50 |

50 |

||

|

Cooling water pump power |

W |

750 |

750 |

750 |

Configuration Introduction

FANUC CNC

High Processing Performance

FANUC 0i-TF PLUS system has powerful high-efficiency processing technology and intelligent servo control technology; high-efficiency processing technology shortens the sequential processing time of external signals according to the acceleration and deceleration of the action state and maximizes the use of servo capabilities, thereby reducing the processing program cycle time; intelligent servo control refers to a servo control function group that can self-optimize and adjust in real time as the machine tool conditions such as load and temperature change, achieving high-speed and high-precision processing.

High Ease Of Use

FANUC 0i-TF PLUS system has a large-capacity program memory, CF card can be used as program memory, USB program can be run with one click, CNC-QSSR function helps machine tools quickly and easily import robots, and the optional system IHMI function provides comprehensive support for work on the processing site, and provides tool information integrated management, processing time prediction, interactive dialogue programming, mechanical collision avoidance, processing data collection, maintenance management and other functions required for each process in the process of "planning", "processing" and "improvement".

High Operation Rate

The IOlinki and FSSB of FANUC Oi-TF PLUS have rich fault detection functions, which can determine the power failure of the I/O module or servo amplifier and the location of the communication cable disconnection. In addition, I/Olinki can detect the output short circuit of each DO point; in addition, the fault diagnosis function can obtain various diagnostic information on the CNC screen that helps to judge the system status when the alarm occurs, helping users to quickly repair the problem area

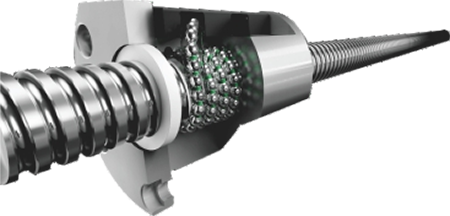

THK Ball Screw

·C3 grade, using high-precision ball screw, with nut pre-loading and screw pre-tensioning treatment to pre-eliminate backlash and temperature rise elongation, showing excellent positioning and repeatability accuracy.

·Servo motor direct drive to reduce backlash error.

THK Roller Linear Guide

·P grade ultra-high rigidity SRG precision grade, linear guide zero clearance, arc cutting, bevel cutting, surface texture is relatively uniform. Suitable for high-speed operation, greatly reducing the driving horsepower required for machine tools.

·Rolling instead of sliding, small friction loss, sensitive response, high positioning accuracy. It can bear the load in the moving direction at the same time, and the track contact surface is still in multi-point contact during the load, and the cutting rigidity will not be reduced.

·Easy to assemble, strong interchangeability, and simple lubrication structure; the wear amount is very small and the service life is long.

SKF Bearing/Oiling Machine

·Automatic lubricator meets the needs of various applications, suitable for various working conditions, reliable products, flexible use.

·Meet the needs of bearing lubrication in high temperature, strong vibration and dangerous environment.

Each lubrication point uses a volumetric proportional distributor to control the lubrication amount, and the machine can be controlled by PLC to accurately supply oil.