Good quality Gantry Drilling Machine - Center Drive lathe For Supporting Roller – Oturn

Good quality Gantry Drilling Machine - Center Drive lathe For Supporting Roller – Oturn Detail:

Double-end CNC lathe

The double-end CNC lathe is an efficient and high-precision machine. The workpiece clampped can turning the outer circle, end face and inner hole at the same time. The production efficiency is higher than the traditional process, and the coaxiality and accuracy of the processed parts are better.

According to customer’s request, loading and unloading auxiliary devices and automatic loading and unloading devices can be provided randomly.The clamping diameter ranges from φ5mm-φ250mm, and the processing length ranges from 140mm-3200mm..

Opposite dual-spindle CNC lathe

The machine tool is mainly used for turning short shaft and small disk parts.

Through the automatic transfer between the two sequences of processing workpieces, the machine completes the processing of the inner hole, outer circle and both ends of the part respectively.

The machine can be equipped with manipulators, automatic loading and unloading and storage devices to complete the fully automated processing of parts.t is specially developed for the turning processing of short shaft and small plate parts.

Supporting Roller Machining Solution

Support roller is one of the important parts of “four wheels and one belt” in crawler bulldozers and hydraulic excavators.

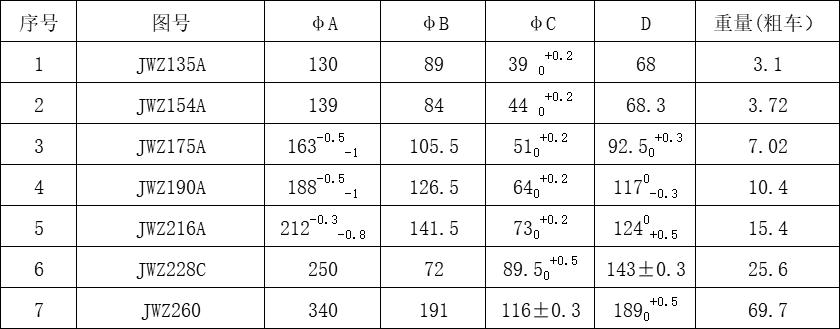

There are 4 specifications of bulldozer rollers and 7 specifications of excavator roller, according to our existing models, we are divided into 3 categories:

Support roller specification range and recommended machine

|

Roller outer diameter (∮A) |

Roller length |

Machine Model |

Max. Clamping diameter |

Headstock width |

|

∮130 |

(About 2D) |

SCK205S |

∮175 |

175 |

|

∮139 |

Blank 136 |

|||

|

∮163 |

Blank 137 |

|||

|

∮188 |

Blank 185 |

∮250 |

280 |

|

|

∮212 |

Rough 234 (finished product 225) |

|||

|

∮250 |

248 |

|||

|

∮340 |

Rough 286 (finished product 279) |

To be developed |

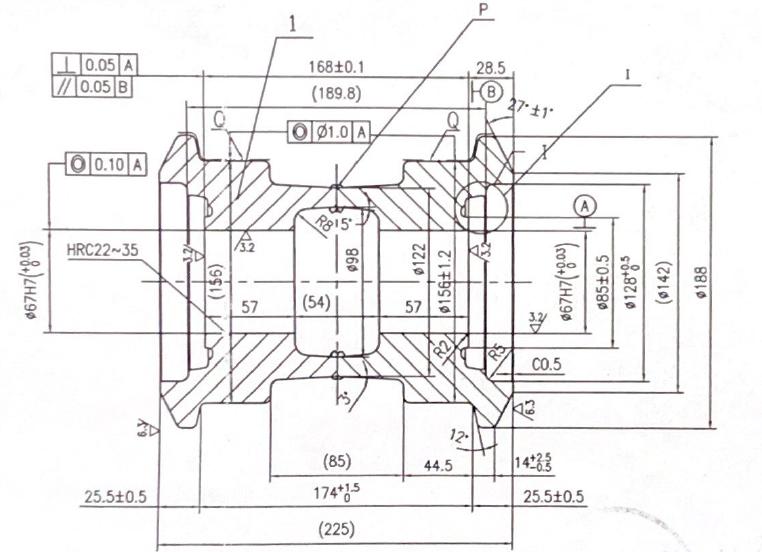

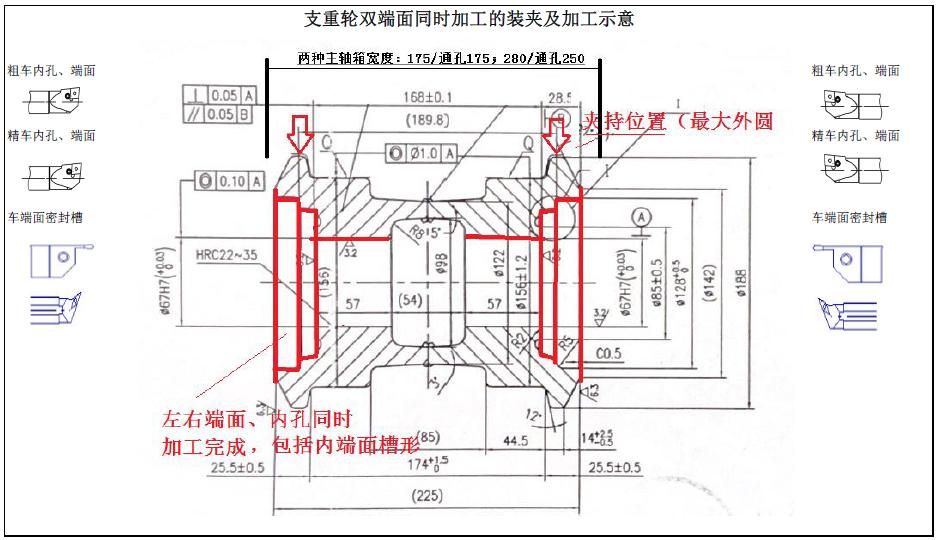

Schematic diagram of supporting roller is processed by the machine as follows

Machine Introduction

SCK205S double-end CNC lathe

■The machine adopts 450 inclined bed layout, which has good rigidity and convenient chip removal.

■The spindle box integrates the three components of the spindle system, fixture and clamping cylinder, with compact structure and reliable work. The fixture is hydraulically clamped. The clamping diameter of the clamp is divided into two blocks.

■The clamp is of collet type. Adjusting claws are installed in the elastic chuck to replace the processing parts and change the clamping diameter. You only need to replace the adjusting claws, which is quick and convenient.

■Multiple boring tools are required according to the machined parts. To avoid interference of the tools, the turret is customized, and the rotating diameter of the cutter head is large. In order to make the turret more rigid, the center height of the turret is 125mm.

■The machine is equipped with a dual-channel control system, and the two tool rests can be linked with the spindle at the same time or separately to complete simultaneous or sequential processing of both ends of the part.

■In order to meet the different requirements of different customers, this machine tool can be equipped with left/right console for customers to choose.

■As for loading and unloading, currently it is manual loading and unloading. Considering the heavy weight of the supporting wheels, truss-type or joint-type automatic loading and unloading devices can be equipped, subject to negotiation with the buyer.

Specification

|

Item |

Name |

Unit |

Specifications |

||

|

Processing range |

Maximum turning diameter of bed |

mm |

Φ550 |

Φ600 |

|

|

Maximum rotating diameter of sliding body |

Φ350 |

||||

|

Maximum clamping diameter |

Φ175 |

Φ250 |

|||

|

Maximum processing length |

Shaft1000;Tube:400 |

||||

|

Spindle speed |

r/min |

1000 |

600 |

||

|

Headstock |

Width of headstock |

mm |

175 |

280 |

|

|

Spindle clamping specifications |

Φ130、139、166 |

Φ188、212、250 |

|||

|

Spindle hole diameter |

Φ175 |

Φ250 |

|||

|

Height from spindle center to ground |

1150 |

||||

|

Feed |

Travel |

X1/X2 |

150/150 |

||

|

Z1/Z2 |

480/600 |

||||

|

Working forward |

X/Z |

mm/r |

0.001~6 |

||

|

Fast forward |

X/Z |

m/min |

16 |

||

|

Tool post |

Drive way |

Slewing servo, locking hydraulic |

|||

|

Number of tools |

Station |

8 |

|||

|

External knife square size |

mm |

□32×32 |

|||

|

Diameter of boring bar |

Φ50 |

||||

|

Machine size (length×width×height ) |

mm |

4920×1860(1910)×1900 |

|||

|

Machine weight |

Net weight |

Kg |

6700 |

||

|

Gross weight |

7700 |

||||

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!