GM5X-N 5 axis CNC Grinding Machine

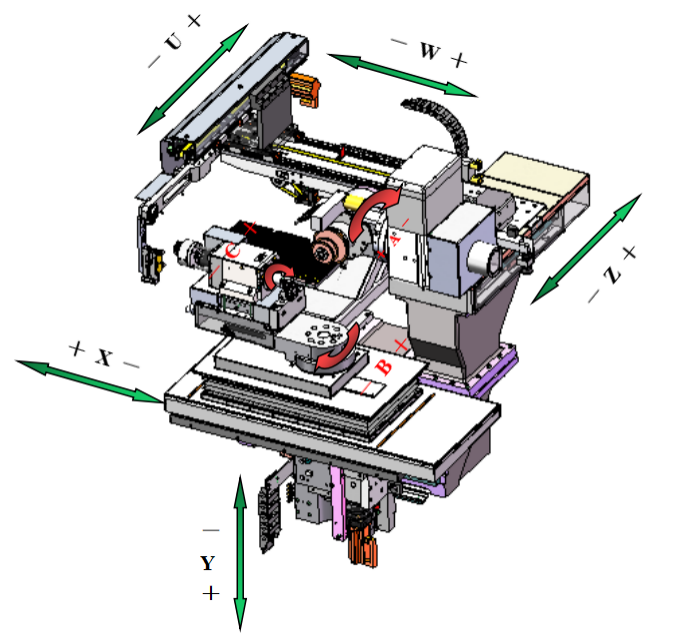

Main structure diagram of machine

Application scope

This machine produces end milling cutter and drills, suitable for the processing of hard alloy and high-speed steel materials.

Tool manufacturing and regrinding cycles

1. Standard end mills: grooving, shovel back, rake sharpening, bottom edge sharpening, digitization, regrinding.

2. Standard drill bit: slotting, outer diameter reduction, apex sharpening, digitization, and grinding.

1. Technical specifications

|

№ |

Content |

Requirement |

Number |

Unit |

|

1.1 |

Workpiece Dimensions | |||

|

1.1.1 |

Clamping length |

≤ |

230 |

mm |

|

1.1.2 |

Clamping diameter |

between |

2-20 |

mm |

|

1.1.3 |

Grinding length |

≤ |

150 |

mm |

|

1.1.4 |

Grinding diameter |

between |

0.2-12 |

mm |

|

1.2 |

Grinding Spindle | |||

|

1.2.1 |

Drive type |

Accurate |

direct drive |

- |

|

1.2.2 |

Power |

rated power |

13.6 |

kW |

|

1.2.3 |

Cooling |

Accurate |

Oil cooled |

- |

|

1.2.4 |

Speed control of grinding wheel |

Accurate |

Stepless-speed |

- |

|

1.2.5 |

Speed |

between |

0-10000 |

rpm |

|

1.2.6 |

Number of spindle grinding heads |

Accurate |

2 |

pcs |

|

1.3 |

Grinding wheel | |||

|

1.3.1 |

Diameter |

≤ |

150 |

mm |

|

1.3.2 |

Maximum number of grinding wheels per spindle |

≤ |

4 |

pcs |

|

1.3.3 |

Grinding wheels spindle diameter |

Accurate |

25 |

mm |

|

1.3.4 |

Program controlled coolant supply |

Accurate |

Yes |

- |

|

1.3.5 |

Number of coolant nozzles |

≥ |

3 |

pcs |

|

1.4 |

Workpiece clamping system | |||

|

1.4.1 |

Clamping system |

Accurate |

Hydraulic, automatic |

- |

|

1.4.2 |

Clamping collet |

Accurate |

SCHAUBLIN W20 |

- |

|

1.4.3 |

Drive type |

Accurate |

direct drive |

- |

|

1.5 |

Axis parameters | |||

|

1.5.1 |

Type |

Accurate |

linear |

- |

|

1.5.2 |

X-axis travel |

≤ |

280 |

mm |

|

1.5.3 |

Z-axis travel |

≤ |

130 |

mm |

|

1.5.4 |

Y-axis travel |

≤ |

230 |

mm |

|

1.5.5 |

X-Y-Z axis resolution |

Accurate |

0.0001 |

mm |

|

1.5.6 |

X-Y-Z axis speed |

≤ |

10 |

m/min |

|

1.5.7 |

A-axis travel |

≤ |

360 |

degree |

|

1.5.8 |

A-axis resolution |

Accurate |

0.0001 |

degree |

|

1.5.9 |

A-axis speed |

≤ |

300 |

rpm |

|

1.5.10 |

B-axis travel |

± |

210 |

degrees |

|

1.5.11 |

B-axis speed |

≤ |

12 |

rpm |

|

1.6 |

Loading and unloading system | |||

|

1.6.1 |

Loading and unloading system |

Accurate |

Truss type robotic arm |

- |

|

1.6.2 |

Number of trays |

Accurate |

2 |

pcs |

|

1.6.3 |

Automatic loading and unloading work-piece diameter |

Between |

2-12 |

mm |

|

1.6.4 |

Automatic loading and unloading work-piece length |

≤ |

40-200 |

mm |

|

1.6.5 |

Maximum number of workpieces |

≤ |

300 |

pcs |

|

1.6.6 |

Software |

Accurate |

Yes |

- |

|

1.7 |

Other components | |||

|

1.7.1 |

Ability to detect workpieces on machine tools |

Accurate |

Yes |

- |

|

1.7.2 |

Centralized automatic lubrication system |

Accurate |

Yes |

|

|

1.7.3 |

Tricolour signall lamp |

Accurate |

Yes |

- |

|

1.8 |

Optional | |||

|

1.8.1 |

Oil mist separation equipment |

Accurate |

Optional |

- |

|

1.9 |

Control | |||

|

1.9.1 |

Control system |

Accurate |

NUM-Flexium+68 |

- |

|

1.9.2 |

Operation panel |

Accurate |

Touch screen |

- |

|

1.9.3 |

Digital control axis |

Accurate |

Yes |

- |

|

1.9.4 |

Color display |

Accurate |

Yes |

- |

|

1.9.5 |

Display Size |

Accurate |

19 |

inch |

|

1.10 |

Tool grinding software module | |||

|

1.10.1 |

Simple milling cutters |

Accurate |

Yes |

- |

|

1.10.2 |

Simple drills |

Accurate |

Yes |

- |

|

1.10.3 |

Probe automatic detection mode |

Accurate |

Yes |

- |

|

1.11 |

Equipment electrical parameters | |||

|

1.11.1 |

Voltage |

Accurate |

380±10% |

V |

|

1.11.2 |

Frequency |

Accurate |

50±10% |

Hz |

|

1.11.3 |

Power |

≤ |

25 |

KW |

|

1.12 |

Dimensions | |||

|

1.12.1 |

Length |

≤ |

2 000 |

mm |

|

1.12.2 |

Width |

≤ |

2 800 |

mm |

|

1.12.3 |

Height |

≤ |

2 200 |

mm |

|

1.12.4 |

Quality |

≤ |

4 750 |

kg |

2. Standard configuration list

|

№ |

Content |

Model |

Brand |

Number |

||

|

2.1 |

Machine tool | |||||

|

2.1.1 |

X-axis configuration | |||||

|

2.1.1.1 |

- Screw rod |

Customized |

NSK |

1pcs |

||

|

2.1.1.2 |

- Rail |

1×MR25-A2-760-20-20-G2-V2+BRK+SOSPL |

SCHNEEBERGER |

2pcs |

||

|

2.1.1.3 |

- Optical scale |

LC483-370 |

HEIDENHAIN |

1pcs |

||

|

2.1.2 |

Y-axis configuration | |||||

|

2.1.2.1 |

- Screw rod |

Customized |

NSK |

1pcs |

||

|

2.1.2.2 |

- Rail |

1×MR35-C2-600-20-20-G2-V2+MRK |

SCHNEEBERGER |

2pcs |

||

|

2.1.2.3 |

- Optical scale |

LC483-370 |

HEIDENHAIN |

1pcs |

||

|

2.1.3 |

Z-axis configuration | |||||

|

2.1.3.1 |

- Screw rod |

Customized |

NSK |

1pcs |

||

|

2.1.3.2 |

- Rail |

1×MR25-A2-850-20-20-G2-V2+BRK+SOSPL |

SCHNEEBERGER |

2pcs |

||

|

2.1.3.3 |

- Optical scale |

LC483-370 |

HEIDENHAIN |

1pcs |

||

|

2.1.4 |

C-axis configuration | |||||

|

2.1.4.1 |

- Angle encoder |

ECN113 |

HEIDENHAIN |

1pcs |

||

|

2.1.4.2 |

- Direct drive motor |

MSP-1000-2-002-158 |

EMB |

1pcs |

||

|

2.1.5 |

B-axis turntable |

WDC-C180 |

GuTian |

1pcs |

||

|

2.1.5 |

A-axis turntable |

WDC-C200L |

GuTian |

1pcs |

||

|

2.1.6 |

Permanent magnet double head electric spindle |

Rated power 7.1KW |

Chuangyun |

1 pcs |

||

|

2.1.7 |

Two axis truss manipulator |

- |

Chuangyun |

1pcs |

||

|

2.1.8 |

Tray |

148-LP-D4 |

Chuangyun |

2pcs |

||

|

2.1.9 |

Tray |

148-LP-D6 |

Chuangyun |

2pcs |

||

|

2.1.10 |

Tray |

148-LP-D8 |

Chuangyun |

2pcs |

||

|

2.1.11 |

Clamping jaw | D0.5-3.2/D3.0-7.0/D7-13 |

Chuangyun |

1set |

||

|

2.1.12 |

High precision V-block |

(3-5) |

Chuangyun |

1pcs |

||

|

2.1.13 |

High precision V-block |

(5-7) |

Chuangyun |

1pcs |

||

|

2.1.14 |

High precision V-block |

(6-12) |

Chuangyun |

1pcs |

||

|

2.1.15 |

Collet |

D4W20 (80-00004) |

SCHAUBLIN |

1pcs |

||

|

2.1.16 |

Probe |

TS150 |

HEIDENHAIN |

1pcs |

||

|

2.1.17 |

Grinding wheel rod(long) |

119×∅31.75×∅96mm |

Chuangyun |

1pcs |

||

|

2.1.18 |

Grinding wheel rod(short) |

87×∅31.75×∅96mm |

Chuangyun |

1pcs |

||

|

2.1.19 |

Air conditioning |

- |

YUEDE |

1pcs |

||

|

2.1.20 |

Tricolour signall lamp |

DC24V |

Schneider |

1pcs |

||

|

2.1.21 |

Flowmeter |

SI5000 |

IFM |

1pcs |

||

|

2.1.22 |

Drive specific power supply |

15KW |

NEWCOM |

1pcs |

||

|

2.1.23 |

Electromagnetic valve group |

M4GE280R-CX-E20D-5-3 |

CKD |

1set |

||

|

2.1.24 |

X,Y, Z-axis automatic lubrication system |

- |

Taiwan |

1set |

||

|

2.2 |

CNC system configuration |

|||||

|

2.2.1 |

BOXPC |

FXPC004NN1HNR10 |

NUM |

1pcs |

||

|

2.2.2 |

Power filter |

AGOFIL024A |

NUM |

1pcs |

||

|

2.2.3 |

Power filter |

AGOFIL001S |

NUM |

1pcs |

||

|

2.2.4 |

Resistance |

AGORES008 |

NUM |

1pcs |

||

|

2.2.5 |

System main power supply |

MDLL3015N00AN0I |

NUM |

1pcs |

||

|

2.2.6 |

Servo driver |

MDLUX021B1CAN0I |

NUM |

4pcs |

||

|

2.2.7 |

B-axis servo motor |

SPX1262N5IA2L02 |

NUM |

1pcs |

||

|

2.2.8 |

A-axis motor |

MDLUX014B1CAN0I |

NUM |

1pcs |

||

|

2.2.9 |

Y-axis servo motor |

SPX0751V5IF2L02 |

NUM |

1pcs |

||

|

2.2.10 |

X/Z-axis servo motor |

MDLUX014B1CAN0I |

NUM |

2pcs |

||

|

2.2.11 |

U/W axis servo driver |

SPX0952N5IA2L02 |

NUM |

2pcs |

||

|

2.2.12 |

V-axis servo motor |

MDLUX014B1CAN0I |

NUM |

1pcs |

||

|

2.2.13 |

Coupler |

SPX0751V5IA2L02 |

NUM |

1pcs |

||

|

2.2.14 |

Input |

SPX0751V5IA2L02 |

NUM |

2pcs |

||

|

2.2.15 |

Output |

EK1100 |

NUM |

2pcs |

||

|

2.2.16 |

Analog input module |

CTMT1809 |

NUM |

1pcs |

||

|

2.2.17 |

Terminator |

CTMT2809 |

NUM |

1pcs |

||

|

2.2.18 |

Operation panel |

CTMT3162 |

NUM |

1pcs |

||

|

2.2.19 |

NCK |

CTMT9011 |

NUM |

1pcs |

||

|

2.2.20 |

NCK |

FXHE02ARE2HE000 |

NUM |

1pcs |

||

|

2.2.21 |

NCK |

FXP2101200 |

NUM |

1pcs |

||

|

2.2.22 |

NCK |

FXSO200061 |

NUM |

1pcs |

||

|

2.2.23 |

NCK |

FXSV994100 |

NUM |

1pcs |

||

|

2.2.24 |

NCK |

FXSO100006 |

NUM |

1pcs |

||

|

2.2.25 |

NCK |

FXSO100008 |

NUM |

1pcs |

||

|

2.2.26 |

NCK |

FXSO100375 |

NUM |

1pcs |

||

|

2.2.27 |

NCK |

FXSO100392 |

NUM |

1pcs |

||

|

2.2.28 |

NCK |

FXPA000586 |

NUM |

1pcs |

||

|

2.2.29 |

NCK |

FXSW282122 |

NUM |

1pcs |

||

|

2.2.30 |

NCK |

FXSW282124 |

NUM |

1pcs |

||

|

2.2.31 |

NCK |

FXSO100012 |

NUM |

1pcs |

||

|

2.3 |

Standard configuration of tool grinding software | |||||

|

2.3.1 |

Simple milling cutter |

Chuangyun self-developed |

1pcs |

|||

|

2.3.2 |

Simple drill |

Chuangyun self-developed |

1pcs |

|||

|

2.3.3 |

3D collision checking with 3D machine simulation |

Chuangyun self-developed |

1pcs |

|||

|

2.3.4 |

3D tool simulation |

Chuangyun self-developed |

1pcs |

|||

|

2.3.5 |

Probe automatic detection |

Chuangyun self-developed |

1pcs |

|||