Gantry Type CNC Drilling And Milling Machine

CNC Gantry Milling And Drilling Machine

Gantry Drilling And Milling Machine

CNC Gantry Milling Machine

Machine Application

BOSM gantry mobile CNC high-speed drilling and milling machine series are mainly used for high-efficiency drilling and processing of large plates, wind power flanges, discs, ring parts and other workpieces with a thickness within the effective range. Drilling through holes and blind holes can be realized on single material parts and composite materials. The machining process of the machine tool is digitally controlled, and the operation is very convenient. It can realize automation, high precision, multiple varieties and mass production. In order to meet the processing needs of different users, the company has developed a variety of finalized products. In addition to conventional models, they can also be designed and customized according to the actual needs of users.

Machine Structure

This equipment mainly consists of bed worktable, movable gantry, movable sliding saddle, drilling and milling power head, automatic lubrication device and protection device, circulating cooling device, digital control system, electrical system, etc. Rolling guide rail pair support and guidance, precision lead screw pair drive, the machine tool has high positioning accuracy and repeat positioning accuracy.

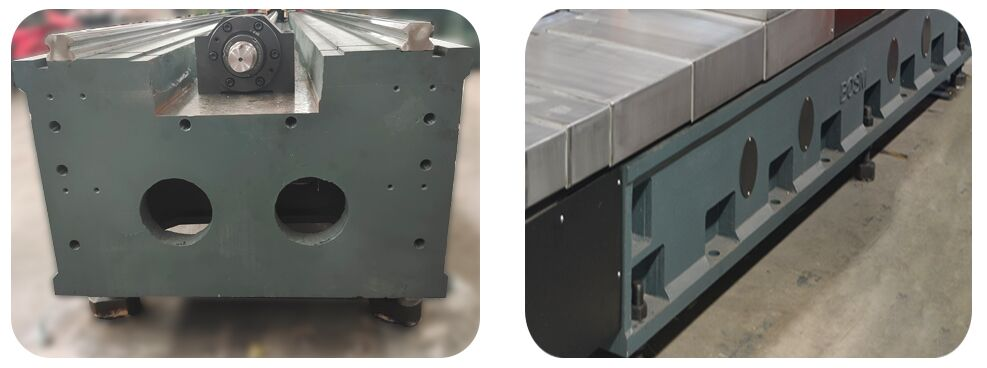

1)Worktable:

The bed is a one-piece casting, finished after secondary annealing and vibration aging treatment, with good dynamic and static rigidity and no deformation. There are T-slots with reasonable finishing layout on the working table surface for clamping workpieces. The bed base is equipped with 2 high-precision linear guides (4 on both sides in total), so that the guide slider is evenly stressed, which greatly improves the rigidity of the machine tool and its tensile and compressive resistance. The drive system adopts AC servo motors and precision ball screw pairs. Side drive makes the gantry move in the X-axis direction. Adjustable bolts are distributed on the bottom surface of the bed, which can easily adjust the level of the worktable of the bed.

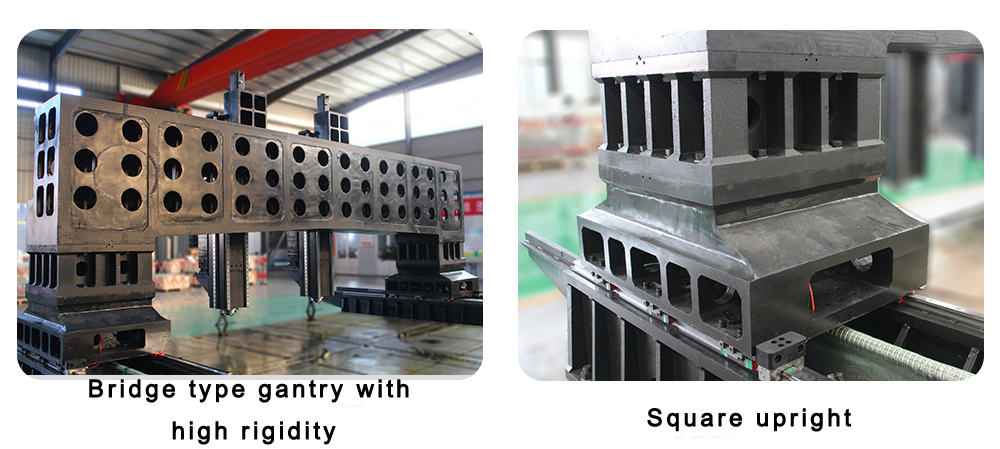

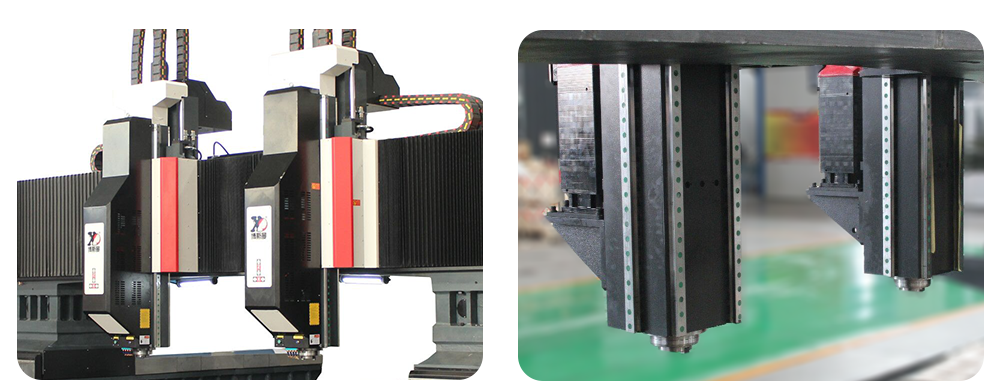

2)Moving gantry:

The movable gantry is cast and processed by gray iron (HT250). Two 55# ultra-high bearing capacity rolling linear guide pairs are installed on the front side of the gantry. A set of precision ball screw pair and a servo motor make the power head slide to move in the Y-axis direction, and the drilling power head is installed on the power head slide. The movement of the gantry is realized by the rotation of the ball screw nut on the ball screw driven by the servo motor through the precision coupling.

3)Moving sliding saddle:

The sliding saddle is a precision cast iron structure. The sliding saddle is equipped with two ultra-high load-bearing CNC linear rail slides, a set of precision ball screw pairs and a high-precision planetary reducer connected to the servo motor, and equipped with nitrogen Balance cylinder, balance the weight of the power head, reduce the load of the lead screw, extend the life of the lead screw, drive the drilling power head to move in the Z-axis direction, and realize the fast forward, work forward, fast reverse, and stop actions of the power head, with automatic Chip breaking, chip removal, pause function.

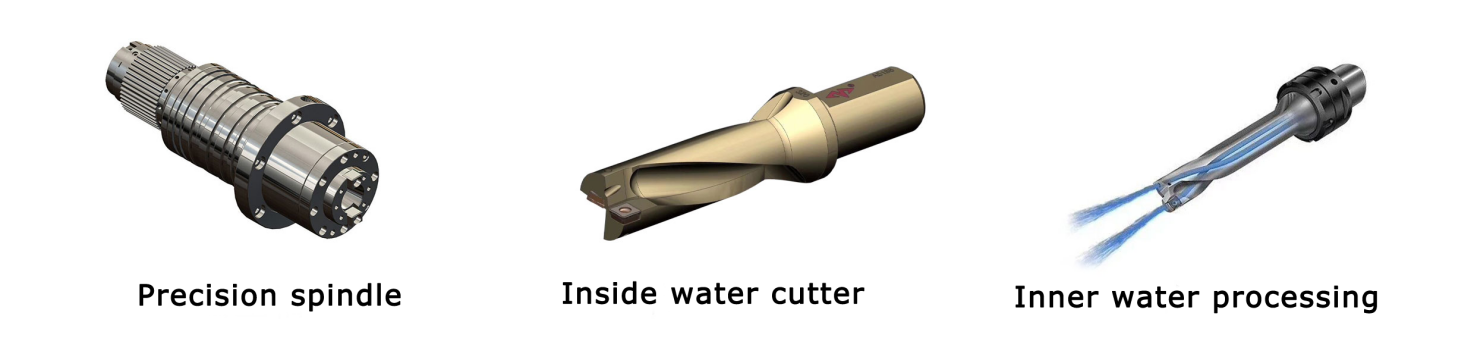

4)Drilling power head(Spindle):

The drilling power head adopts a dedicated servo spindle motor, which is driven by a toothed synchronous belt deceleration to increase torque and drives a dedicated precision spindle. The spindle adopts the first four and the rear two six rows of Japanese angular contact bearings to achieve stepless speed change. The spindle is equipped with a pneumatic tool change system to make the tool The replacement is quick and easy, and the feed is driven by a servo motor and a ball screw. The X and Y axes can be linked, using semi-closed loop control, which can realize linear and circular interpolation functions. The spindle end is a BT50 taper hole, equipped with Italian Rotofors high-speed rotary joint, which can be processed by high-speed U-drilling center.

4.1 The box body and sliding table of the drilling power head are made of castings to enhance their rigidity and stability, and reduce vibration and noise.

4.2 The machine tool can be operated by an electronic handwheel; in order to save time and improve production efficiency during processing, after drilling the first hole to set the feed position, drilling the remaining holes of the same kind can achieve fast forward → work advance → fast reverse It should also have functions such as automatic chip breaking, chip removal, and pause.

4.3 The ram is equipped with a liquid nitrogen balance system to reduce the Z-axis load and increase the service life of the Z-axis screw.

4.4 The Z-axis servo motor adopts a power-off brake motor, which will hold the brake when the power is suddenly cut to avoid accidents caused by the falling of the spindle box.

4.5 Headstock

4.5.1. The main shaft box adopts four heavy-duty linear guides, with high rigidity of motion, high positioning accuracy, and good low-speed stability.

4.5.2. Z-axis drive-the servo motor is directly connected to the ball screw through the coupling, and the ball screw drives the headstock to move up and down on the saddle to realize the Z-axis feed. The Z-axis motor has an automatic brake function. In the event of a power failure, the motor shaft is tightly held to prevent it from rotating.

4.5.3. The spindle group adopts Taiwan Jianchun high-speed internal water outlet spindle, which has high precision and high performance. The main shaft grasps the knife by the butterfly spring on the main shaft with the tension force acting on the pull nail of the tool handle through the four-part broach mechanism, and the loose tool adopts pneumatic method.

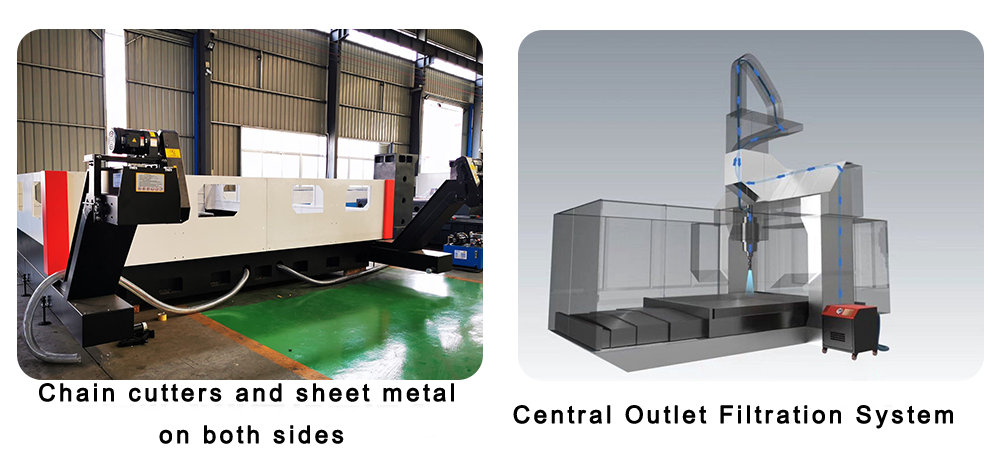

5)Automatic lubrication device and protective device:

There is an automatic chip conveyor on both sides of the workbench and a filter at the end. The automatic chip conveyor is a flat chain type. One side is equipped with a cooling pump, and the outlet is connected to the central water filter system with a hose. , The coolant flows into the chip conveyor, the chip conveyor lift pump pumps the coolant into the central outlet filter system, and the high-pressure cooling pump circulates the filtered coolant to the spindle drilling cooling. It is also equipped with a chip transport trolley, which is very convenient to transport chips. This equipment is equipped with internal and external tool cooling systems. When high-speed drilling is used, internal cooling of the tool is used, and external cooling is used for light milling.

5.1. Central outlet water filtration system:

This machine tool is equipped with a central water filter system, which can effectively filter impurities in the coolant. The internal water spray system can prevent iron pins from being entangled on the tool during processing, reduce tool wear, extend tool life, and improve the surface finish of the workpiece. The tool tip high-pressure water discharge pin can well protect the surface of the workpiece, protect the high-speed rotary joint, prevent impurities from blocking the rotary joint, and improve the quality of the workpiece as a whole, and improve work efficiency.

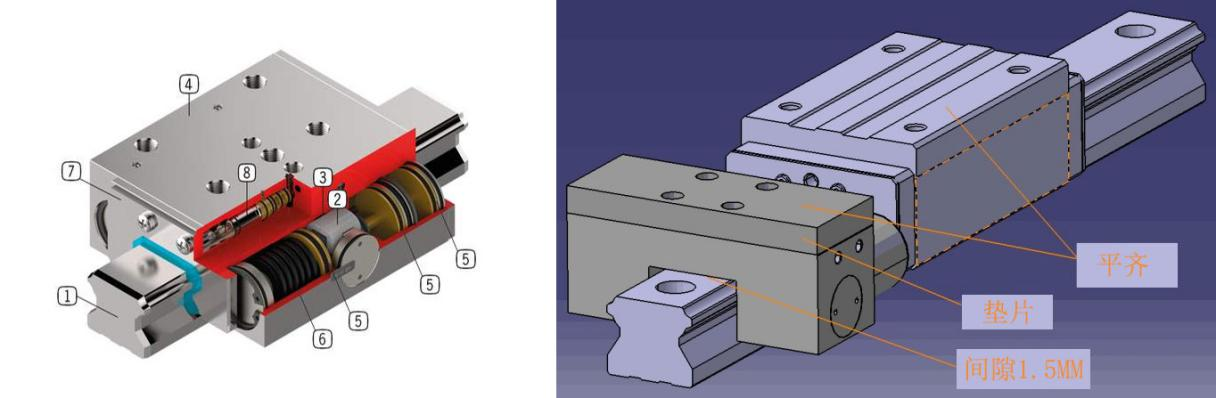

6) Linear Clamper:

The clamp is composed of the main body of the clamp, actuators, etc. It is a high-performance functional component used in conjunction with the rolling linear guide pair. Through the principle of wedge block force expansion, it generates a strong clamping force; it has a fixed gantry, precise positioning, anti-vibration and Function to improve stiffness.

It has the following characteristics:

Safe and reliable, strong clamping force, clamping the non-moving XY axis during drilling and tapping processing.

The extremely high clamping force increases the rigidity of the axial feed and prevents fretting caused by vibration.

Quick response, the opening and closing response time is only 0.06 seconds, which can protect the machine tool and increase the life of the lead screw.

Durable, nickel-plated surface, good anti-rust performance.

Novel design to avoid rigid impact when tightening.

7) Positioning and clamping of the workpiece

For round flange workpiece alignment, it can be arbitrarily placed on the support plate with T-slots, and the center position is measured by the edge finder installed in the spindle taper hole at any three points (inner diameter or outer diameter) on the workpiece. After that, it is automatically obtained by numerical control program calculation, which is accurate and fast. The clamping of the workpiece is clamped by a clamp composed of a pressing plate, an ejector rod, a tie rod and a cushion block, which is convenient to use.

8) Automatic lubrication device

This machine tool is equipped with Taiwan's original volumetric partial pressure automatic lubrication device, which can automatically lubricate various motion pairs such as guide rails, lead screws, racks, etc., without dead ends, and ensure the service life of the machine tool. The guide rails on both sides of the machine bed are equipped with stainless steel protective covers, and both sides of the moving gantry power head are equipped with flexible protective covers. Water-proof splash guards are installed around the worktable, and the water pipe line is protected by the plastic drag chain. A soft transparent PVC strip curtain is installed around the spindle.

9) Full digital CNC controller:

9.1. With chip breaking function, the chip breaking time and chip breaking cycle can be set on the man-machine interface.

9.2. With the tool lifting function, the tool lifting height can be set on the man-machine interface. When drilling to this height, the drill bit is quickly lifted to the top of the workpiece, and then shavings, then fast forward to the drilling surface and automatically converted to work feed.

9.3. The centralized operation control box and handheld unit adopts numerical control system, and is equipped with USB interface and LCD liquid crystal display. In order to facilitate programming, storage, display and communication, the operation interface has functions such as man-machine dialogue, error compensation, and automatic alarm.

9.4. The equipment has the function of preview and re-inspection of the hole position before processing, which is very convenient to operate.

10)Optical edge finder:

The equipment is equipped with a photoelectric edge finder, which can find the position of the workpiece conveniently and quickly.

1) Install the edge finder into the spindle chuck of the machine tool, and slowly rotate the spindle to correct its concentricity.

2) Move the spindle with the handwheel, so that the edge of the edge finder's steel ball touches the workpiece lightly, and the red light is turned on. At this time, the spindle can be moved forward and backward repeatedly to find the best point where the edge of the edge finder's steel ball touches the workpiece. .

3) Record the X and Y axis values displayed by the CNC system at this time, and fill in the computer.

4) Find multiple detection points in this way

11) Tool wear alarm

The tool wear alarm mainly detects the current of the spindle motor. When the current exceeds the preset value, the device automatically judges that the tool has worn out, and the spindle will automatically retract the tool at this time, and the automatic program will end. Remind the operator that the tool has worn out.

12) Low water level alarm

1) When the coolant in the filter is at the middle level, the system automatically connects to the motor to start, and the coolant in the chip conveyor automatically flows into the filter. When it reaches the high level, the motor automatically stops working.

2) When the coolant in the filter is at a low level, the system will automatically prompt the level gauge to alarm, the spindle will automatically retract the tool, and the machine will stop working.

13) Power-off memory function

Due to the operation stop caused by sudden power failure, this function can quickly and conveniently find the position of the last hole drilled before the power failure. Operators can quickly proceed to the next step, saving search time.

Three-axis laser inspection:

Each machine of Bosman is calibrated with the laser interferometer of the British company RENISHAW, and accurately inspects and compensates the pitch error, backlash, positioning accuracy, repeat positioning accuracy, etc., to ensure the dynamic, static stability and processing accuracy of the machine . Ballbar inspection Each machine uses a British RENISHAW company ballbar to calibrate the true circle accuracy and machine geometric accuracy. At the same time, a circular cutting experiment is carried out to ensure the machine's 3D machining accuracy and circle accuracy.

Platform layout, workpiece clamping, automatic chip removal requirements

1. Main platform (1 pcs): T-slot clamping work piece. Both the upper end surface and the side surface of the main platform can be used as processing positioning surfaces.

2. Sinking platform (1 pcs): (the side is equipped with auxiliary press-fitting frame, and the top is equipped with full-covering protective cover, designed and installed by the seller), the main workpiece positioning and processing instructions:

Valve cover processing: positioning of the lower platform (bottom support handle and workpieces of different sizes), the upper pressure plate is fixed by pressing or the seller designs an automatic top clamping device.

Valve body processing: positioning of the lower platform (bottom support handles and workpieces of different sizes), the side handles of the auxiliary column of the lower platform and the L-shaped accessory ejector rods are pressed and fixed or the seller designs an automatic top clamping device.

Specification

|

Model |

BOSM-DS3030 |

BOSM-DS4040 |

BOSM-DS5050 |

BOSM-DS6060 |

|

|

Working Size |

length*width |

3000*3000 |

4000*4000 |

5000*5000 |

6000*6000 |

|

Vertical Drilling Head |

Spindle taper |

BT50 |

|||

|

Drilling Diameter (mm) |

φ96 |

||||

|

Tapping Diameter(mm) |

M36 |

||||

|

Spindle Speed (r/min) |

30~3000/60~6000 |

||||

|

Spindle Motor Power (kw) |

22/30/37 |

||||

|

Spindle Nose To Table Distance |

According to the foundation |

||||

|

Repeat Positioning Accuracy(X/Y/Z) |

X/Y/Z |

±0.01/1000mm |

|||

|

Control System |

KND/GSK/SIEMENS |

||||

|

Magazine Tool |

Okada magazine tool with 24 tools as optional |

||||

Quality Inspection

Each machine of Bosman is calibrated with a laser interferometer from the United Kingdom RENISHAW company, which accurately inspects and compensates for pitch errors, backlash, positioning accuracy, and repeated positioning accuracy to ensure the machine's dynamic, static stability, and processing accuracy. . Ball bar test Each machine uses a ball bar tester from the British RENISHAW company to correct the true circle accuracy and machine geometric accuracy, and perform circular cutting experiments at the same time to ensure the machine's 3D machining accuracy and circle accuracy.

Machine tool use environment

1.1 Equipment environmental requirements

Maintaining a constant level of ambient temperature is an essential factor for precision machining.

(1) Available ambient temperature is -10 ℃ ~ 35 ℃. When the ambient temperature is 20 ℃, the humidity should be 40 ~ 75%.

(2) In order to keep the static accuracy of the machine tool within the specified range, the optimal ambient temperature is required to be 15 ° C to 25 ° C with a temperature difference

It should not exceed ± 2 ℃ / 24h.

1.2 Power supply voltage: 3-phase, 380V, voltage fluctuation within ± 10%, power supply frequency: 50HZ.

1.3 If the voltage in the use area is unstable, the machine tool should be equipped with a regulated power supply to ensure the normal operation of the machine tool.

1.4. The machine tool should have reliable grounding: the grounding wire is copper wire, the wire diameter should not be less than 10mm², and the grounding resistance is less than 4 ohms.

1.5 In order to ensure the normal working performance of the equipment, if the compressed air of the air source fails to meet the requirements of the air source, a set of air source purification devices (dehumidification, degreasing, filtering) should be added before the machine's air intake.

1.6. The equipment should be kept away from direct sunlight, vibration and heat sources, and away from high-frequency generators, electric welding machines, etc., so as to avoid machine production failure or loss of machine accuracy.

Before&After Service

1)Before Service

Through study the request and necessary information from customers then feedback to our engineers, the Bossman Technical team is responsible for the technical communication with the customers and the formulation of solutions, assisting customer in selecting the appropriate machining solution and suitable machines.

2)After Service

A.The machine with one-year warranty and paid for life-long maintenance.

B.During the one-year warranty period after the machine arrived in destination port, BOSSMAN will provide free and timely maintenance services for various non-man-made faults on machine, and timely replace all kinds of non-man-made damage parts free of charge . Failures occurring out the warranty period shall be repaired at appropriate charges.

C.Technical support in 24 hours online, TM, Skype, E-mail, solving the relative questions in time. if cannot be resolved,BOSSMAN will immediately arrange for after-sales engineer to arrive on-site for repair,buyer need pay for the VISA, flights tickets and accommodation.

Customer’s Site