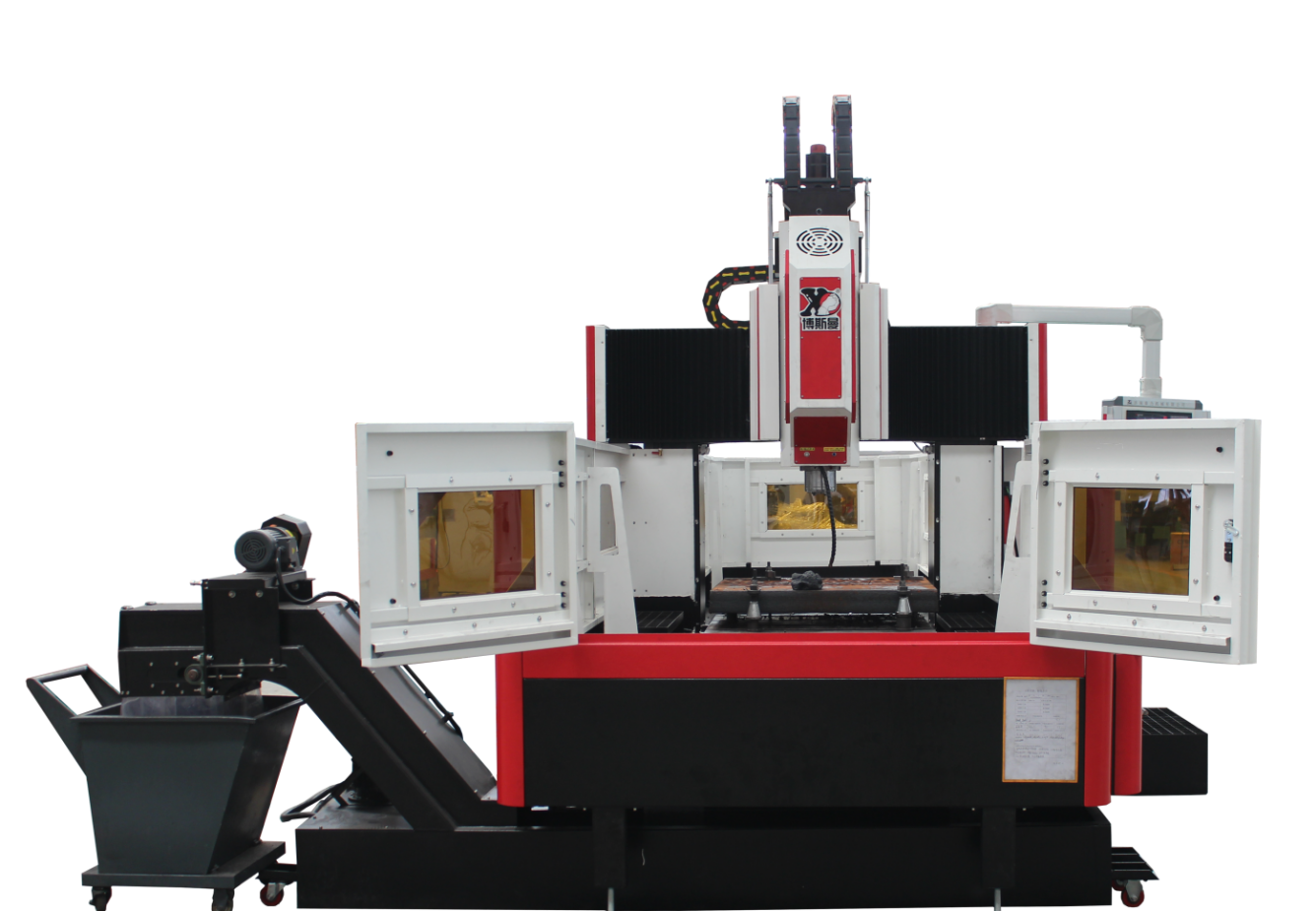

Fixed Beam CNC Drilling and Milling Machine

CNC Drilling And Milling Machine

Machine Function And Feature Description

1) CNC gantry drilling and milling machine is a machining equipment that integrates advanced technologies such as machinery, electricity, and hydraulics. It is mainly used for processing mould, flanges, valves, structural parts ect. It is widely used in the roughing and finishing of complex parts such as various plates, boxes, frames,mould etc. in the machinery manufacturing industry. This machine tool can realize the horizontal (Y-axis) and vertical movement (Z-axis) of the vertical milling head and the table Three-axis linkage of longitudinal movement (X axis). Multi-process processing such as milling, boring, drilling, rigid tapping, reaming, and countersinking can be performed. The whole machine adopts a gantry frame structure, with high rigidity and good accuracy retention. It is the first choice for users to process.

2) Overall layout of machine

(1)The fixed beam type gantry frame structure is adopted, the bed is fixed, and the double column and the bed are connected by bolts. The worktable moves in the X axis on the bed, the headstock moves in the Z direction on the saddle, and the saddle and the headstock move in the Y direction on the beam.

(2)The main large parts of the machine tool: bed, column, beam, saddle, and headstock are all high-strength cast iron materials. These large parts are optimized by 3D computer software, with reasonable layout of ribs and complete heat treatment processes to eliminate residual stress. , To ensure that the whole machine has sufficient strength, rigidity and high stability, cutting vibration resistance .

3 )Bed-Workbench

(1) The bed is made of high-strength HT250 cast iron material, using computer three-dimensional aided optimization design, the ribs are arranged reasonably, and its rigidity and strength are improved.

(2) The X-axis guideway pair adopts imported heavy-duty linear guides, with low dynamic and static friction coefficient, high table sensitivity, low high-speed vibration, low-speed no crawling, high positioning accuracy, and excellent servo drive performance: at the same time, the load capacity is large, and the cutting vibration resistance is good. .

(3) X-axis drive-the servo motor is connected with the ball screw through the reducer, which drives the worktable to move back and forth on the bed to realize the X-axis feed movement and pre-stretch the screw to improve the Stiffness.

4 )Beam

(1) The crossbeam and the column are integrated into the gantry frame structure, using high-strength HT250 cast iron material, the ribs are arranged reasonably, and have sufficient bending and torsion rigidity.

(2) The beam guide pair adopts heavy linear guide.

(3) Y-axis drive-the servo motor is directly connected with the ball screw through the coupling, and the ball screw drives the saddle to move left and right on the beam to realize the Y-axis feed movement.

5)Headstock

(1) The headstock adopts heavy-duty roller linear guide, which has high rigidity of motion, high positioning accuracy, and good low-speed stability.

(2) Z-axis drive-the servo motor is directly connected to the ball screw through the coupling, and the ball screw drives the headstock to move up and down on the saddle to realize the Z-axis feed. The Z-axis motor has an automatic brake function. In the event of a power failure, the motor shaft is tightly held to prevent it from rotating.

(3) The spindle group adopts Taiwan Jianchun high-speed internal cooling spindle with high precision and high performance. The main shaft grasps the knife by the butterfly spring on the main shaft with the tension force acting on the pull nail of the tool handle through the four-part broach mechanism, and the loose tool adopts pneumatic method.

6)Pneumatic system

Used to loosen the tool of the spindle.

7) Machine protection

The bed rail (X axis) adopts stainless steel telescopic protective cover;

The beam guide (Y axis) adopts flexible organ protection.

8) Lubrication

(1) X, Y, Z three-axis bearings are all greased.

(2) X, Y, Z three-axis guideways are all lubricated by oil.

(3) X, Y, Z three-axis ball screw pairs are all lubricated by oil.

9) CNC system

The CNC system is standard equipped with Beijing Kaiendi control system and drive, with complete functions and easy operation; standard RS-232 communication interface, USB socket and related software.

Filtering System

This machine tool is equipped with a central water filter system, which can effectively filter impurities in the coolant. The internal water spray system can prevent iron pins from being entangled on the tool during processing, reduce tool wear, extend tool life, and improve workpiece surface finish. The tool tip high-pressure water outlet pin can well protect the surface of the workpiece, protect the high-speed rotary joint, prevent impurities from blocking the rotary joint, and improve the overall quality of the workpiece and improve work efficiency. (Note picture is the physical picture of the filter system)

Specification

|

Model |

BOSM-DPH2016 |

BOSM-DPH2022 |

BOSM-DPH2625 |

BOSM-DPH4026 |

|

|

Working size(mm) |

2000*1600 |

2000*2000 |

2500*2000 |

4000*2200 |

|

|

Max.loading(Kg) |

7000 |

7000 |

7000 |

7000 |

|

|

T Slot(mm) |

8*22 |

8*22 |

8*22 |

8*22 |

|

|

Maximum travel of table-X axis(mm) |

2200 |

2200 |

2600 |

4000 |

|

|

Maximum travel of table-Y axis(mm) |

1600 |

2200 |

2500 |

2600 |

|

|

Spindle maximum stroke-Z axis(mm) |

600 |

600 |

600 |

600/1000 |

|

|

Distance from spindle end to worktable(mm) |

Maximum |

800 |

800 |

800 |

800 |

|

Minimum |

200 |

200 |

200 |

200 |

|

|

Tapper(7:24) |

BT50 |

BT50 |

BT50 |

BT50 |

|

|

Spindle speed(r/min) |

30~3000/60~6000 |

30~3000/60~6000 |

30~3000/60~6000 |

30~3000/60~6000 |

|

|

Spindle motor power(Kw) |

22 |

22 |

22 |

22 |

|

|

Max. U-drill(mm) |

φ90 |

φ90 |

φ90 |

φ90 |

|

|

Maximum tapping(mm) |

M36 |

M36 |

M36 |

M36 |

|

|

Cutting feed speed range |

1~4000 |

1~4000 |

1~4000 |

1~4000 |

|

|

Rapid movement(m/min) |

2008/8/8 |

2008/8/8 |

2008/8/8 |

2008/8/8 |

|

|

Implementation of national standards GB/T18400.4(m/min) |

±0.01/1000mm |

±0.01/1000mm |

±0.01/1000mm |

±0.01/1000mm |

|

|

Weight(T) |

16.5 |

21 |

24 |

40 |

|

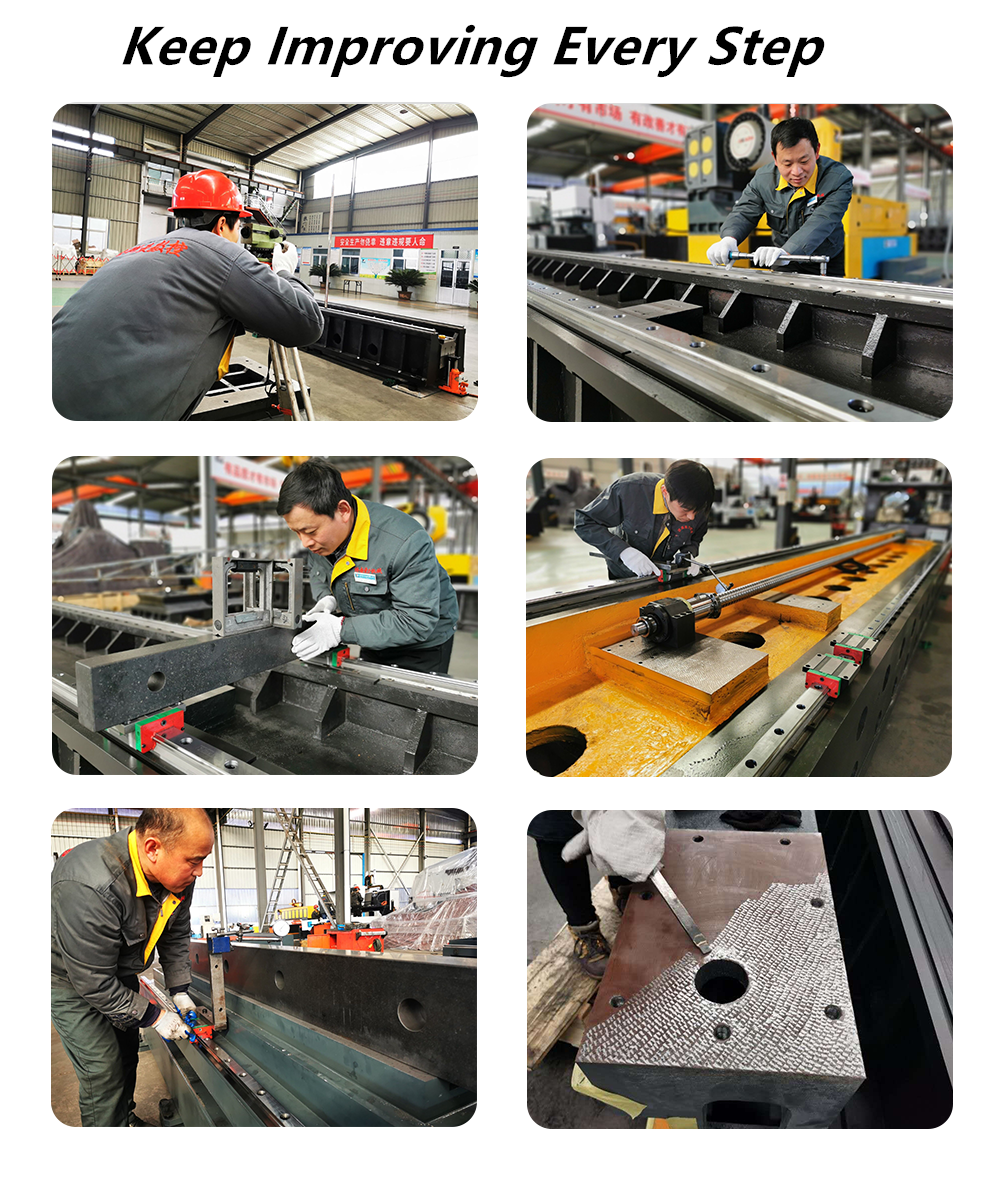

Quality Inspection

Each machine of Bosman is calibrated with a laser interferometer from the United Kingdom RENISHAW company, which accurately inspects and compensates for pitch errors, backlash, positioning accuracy, and repeated positioning accuracy to ensure the machine's dynamic, static stability, and processing accuracy. . Ball bar test Each machine uses a ball bar tester from the British RENISHAW company to correct the true circle accuracy and machine geometric accuracy, and perform circular cutting experiments at the same time to ensure the machine's 3D machining accuracy and circle accuracy.

Machine tool use environment

1.1 Equipment environmental requirements

Maintaining a constant level of ambient temperature is an essential factor for precision machining.

(1) Available ambient temperature is -10 ℃ ~ 35 ℃. When the ambient temperature is 20 ℃, the humidity should be 40 ~ 75%.

(2) In order to keep the static accuracy of the machine tool within the specified range, the optimal ambient temperature is required to be 15 ° C to 25 ° C with a temperature difference

It should not exceed ± 2 ℃ / 24h.

1.2 Power supply voltage: 3-phase, 380V, voltage fluctuation within ± 10%, power supply frequency: 50HZ.

1.3 If the voltage in the use area is unstable, the machine tool should be equipped with a regulated power supply to ensure the normal operation of the machine tool.

1.4. The machine tool should have reliable grounding: the grounding wire is copper wire, the wire diameter should not be less than 10mm², and the grounding resistance is less than 4 ohms.

1.5 In order to ensure the normal working performance of the equipment, if the compressed air of the air source fails to meet the requirements of the air source, a set of air source purification devices (dehumidification, degreasing, filtering) should be added before the machine's air intake.

1.6. The equipment should be kept away from direct sunlight, vibration and heat sources, and away from high-frequency generators, electric welding machines, etc., so as to avoid machine production failure or loss of machine accuracy.

Before&After Service

1)Before Service

Through study the request and necessary information from customers then feedback to our engineers, the Bossman Technical team is responsible for the technical communication with the customers and the formulation of solutions, assisting customer in selecting the appropriate machining solution and suitable machines.

2)After Service

A.The machine with one-year warranty and paid for life-long maintenance.

B.During the one-year warranty period after the machine arrived in destination port, BOSSMAN will provide free and timely maintenance services for various non-man-made faults on machine, and timely replace all kinds of non-man-made damage parts free of charge . Failures occurring out the warranty period shall be repaired at appropriate charges.

C.Technical support in 24 hours online, TM, Skype, E-mail, solving the relative questions in time. if cannot be resolved,BOSSMAN will immediately arrange for after-sales engineer to arrive on-site for repair,buyer need pay for the VISA, flights tickets and accommodation.

Customer’s Site