Five-axis Vertical Machining Center CTB Series

Features

Machine introduction

1.Cost-effective five-axis simultaneous machining

Classic C-type structure, equipped with self-developed high-precision electric spindle and direct-drive rotary table, high-end CNC system, perfectly presents excellent quality. Supports optional electric spindles of various specifications and turning and milling compound rotary tables.

2.Direct-drive turntable

The self-developed direct-drive turntable adopts high-precision torque motor, zero transmission gap, no wear, and is equipped with high-precision angle encoder.

High-end CNC system achieves high dynamic precision control.

Swivel turntable, five-axis linkage processing, maximum workpiece weight 150kg-3000kg, and negative angle processing can be achieved. The B axis is equipped with an auxiliary support structure with strong support rigidity.

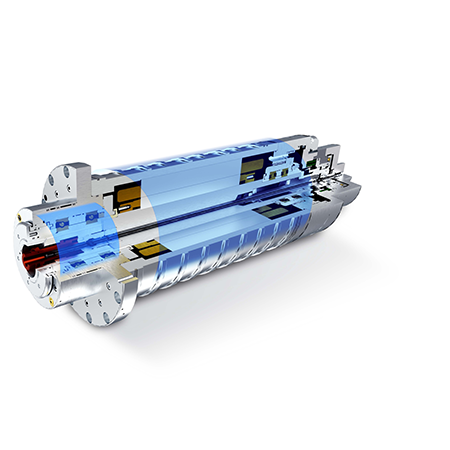

3.HSK series electric spindle

The electric spindle adopts high-efficiency asynchronous internal motor, high-precision ceramic bearings, vibration sensor, temperature sensor and tool internal cooling functions are optional.

4. The lubrication system adopts long-lasting grease lubrication;

5. The cooling system uses a large-flow cooling pump to fully meet the cooling needs of spindle tools and workpieces. The cooling medium is determined according to the actual conditions of the user's workpieces;

6. The chip removal system adopts a chain plate automatic chip removal machine (rear row)

7. The ATC tool changing cam box of the tool magazine is equipped with automatic monitoring of lubricating oil levels to reduce major damage to the equipment caused by blind spots in manual maintenance;

8. Machine tool design prioritizes maintenance. The layout of the large parts of this machine tool is based on the open principle, which is convenient for installation, adjustment and maintenance, and maintenance windows have been left in some parts;

9. The machine tool is easy to use, operate and maintain and has beautiful appearance. The use and maintenance of machine tools will not endanger personal health or pollute the environment;

Technical Specifications

|

Item |

Unit |

V5-320B |

V5-630B |

V5-1000A |

||||

|

Table |

||||||||

|

Diameter |

mm |

320 |

630 |

1000 |

||||

|

Max. horizontal load |

kg |

150 |

500 |

3000 |

||||

|

Max. vertical load |

100 |

300 |

2000 |

|||||

|

T-slots (number X width) |

No. X mm |

8X10H8 |

8X14H8 |

5X18 |

||||

|

Machining range |

||||||||

|

Distance from spindle nose |

Max.(mm) |

430 |

550 |

1080 |

||||

|

to table surface |

Min.(mm) |

100 |

150 |

180 |

||||

|

X-axis |

mim |

450 |

600 |

1150 |

||||

|

Y-axis |

mm |

320 |

450 |

1300 |

||||

|

Z-axis |

mm |

330 |

400 |

900 |

||||

|

B-axis |

。 |

-35~ +110 |

-35~ +110 |

-150~ +130 |

||||

|

C-axis |

。 |

n X 360 |

n X 360 |

n X 360 |

||||

|

Spindle |

||||||||

|

Tool holder |

|

BT30 |

HSKE40 |

BT40 |

HSKA63 |

BT50 |

HSKA100 |

|

|

Pull stud |

|

MAS403 BT30-I |

|

MAS403 BT40-I |

|

MAS403 BT50-I |

|

|

|

Rated speed |

rpm |

12000 |

17500 |

1800 |

2000 |

1500 |

||

|

Max. speed |

24000 |

32000 |

12000 |

18000 |

10000 |

|||

|

Motorized spindle output torque (S1/S6) |

Nm |

12/15.5 |

6/8.2 |

69/98 |

72/88 |

191/236 |

||

|

Motorized spindle output power (S1/S6) |

kW |

15/19.5 |

11/15 |

13/18.5 |

15/18.5 |

30/37 |

||

|

Coordinate axis |

||||||||

|

Rapid traverse |

X-axis |

m/min |

36 |

36 |

25 |

|||

|

Y-axis |

36 |

36 |

25 |

|||||

|

Z-axis |

36 |

36 |

25 |

|||||

|

Max. speed |

B-axis |

rpm |

100 |

|

15 |

|||

|

C-axis |

80 |

|

||||||

|

130 |

80 |

30 |

||||||

|

Automatic tool changer |

||||||||

|

Type |

Disk type |

Disk type |

Horizontal chain type servo automatic tool changer |

|||||

|

Tool selection |

Bidirectional proximity principle

|

Bidirectional proximity principle

|

Bidirectional proximity principle |

|||||

|

Capacity |

T |

24/30 |

24 |

30 |

||||

|

Max. tool length |

mm |

200 |

300 |

400 |

||||

|

Ma tool weight |

kg |

3.5 |

8 |

20 |

||||

|

Max disk diameter |

Full |

mm |

65 |

80 |

125 |

|||

|

|

Adjacent positions empty |

125 |

150 |

180 |

||||

|

Accuracy |

||||||||

|

Implementation Standards |

GB/T 20957 |

GB/T 20957 |

GB/T 20957 |

|||||

|

Positioning accuracy |

X/Y/Z axis |

mm

|

0.006 |

0.007 |

0.08 |

|||

|

|

B/C axis |

“ |

6 |

6 |

8 |

|||

|

Repeatability |

X/Y/Z axis |

mm |

0.004 |

0.005 |

0.006 |

|||

|

B/C axis |

“ |

4 |

4 |

6 |

||||

|

Weight |

kg |

4000 |

6500 |

33000 |

||||

|

Capacity |

KVA |

45 |

45 |

80 |

||||

|

Overall dimensions (LXWXH) |

mm |

3460 X 3000X 2335 |

4000 X 4000X 3200 |

7420X4800X4800 |

||||

Processing Cases

Mobile Phone Parts

Structural Parts

Ornaments

Impellers

Bridge Plating

Valve Bodies