Five-axis Milling And Turning Machine FH Series

Features

1.The five-axis linkage milling and turning compound machining center can realize multiple functions in one machine:

vertical and horizontal conversion, capable of milling and turning; one-time clamping, multi-process and multi-angle processing and forming.

2.Precision is a never-ending attitude

The highly stable and high-precision structure also improves the overall rigidity, and the basic structure is further optimized using finite element calculations.

3.Easy operation and precise control

The operating table designed according to ergonomics can meet the ideal needs of different working environments according to different needs, realize close observation and monitoring of the entire processing process, achieve the best operation performance, and ensure the accuracy of control. The built-in operating system can realize the continuous management, documentation and visualization of orders, processes and machine tool data, making operation easier and more focused on product production.

3.1Ergonomic design

Equipped with 19" multi-touch display,multi-angle rotation and lifting, and IPS full-view screen, and traditional PC keyboard connection host input mode

3.2Unified

All models have a unified operating interface, no need for additional adaptation

3.3Continuously

Centralized management of job, process and machine data

3.4Compatible

Realize compatibility, transmission and networking of files in various formats

4.Powerful 5-axis universal milling head

Significantly increased and improved interference profiles and stiffness

The B-axis with DD motor direct drive has a larger YRT bearing to improve rigidity, which can achieve high torque cutting in linkage state, equipped with Heidenhain circular grating and full closed-loop control, for precise feeding.

5.Turning and milling worktable

DD motor drives the turning and milling table directly without transmission chain, without gap and high dynamics, and can complete turning and milling processing in one clamping on a machine tool. The high-load-capacity rotary table has a maximum load of 4T.

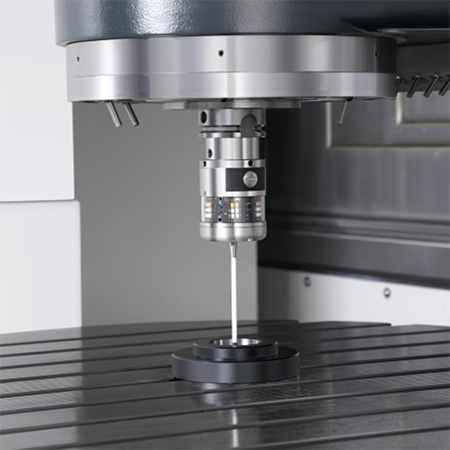

6.Optical touch-trigger probe

Equipped with OMP60 ultra-small 3D trigger optical probe for on-machine workpiece alignment and inspection, it saves 90% of on-machine auxiliary time and reduces scrap rate.

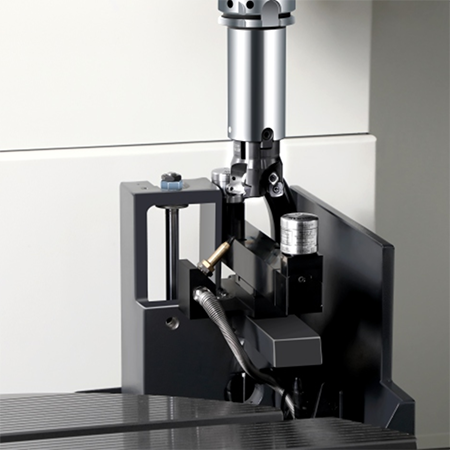

7.Laser tool setter

The non-contact laser tool setting instrument can be raised and lowered, and the tool can be automatically set on the machine. The tool compensation is automatically updated, making the processing accuracy more accurate!

Standard Technical Specifications

|

Item |

FH60P-C |

FH80P-C |

FH100P-C |

|

X/Y/Z axis travel |

600mm*800mm*600mm |

800mm×1050mm×800m |

1000mm×1150mm×1000mm |

|

Distance from horizontal milling head center to worktable |

30mm-630mm |

39mm-839mm |

30mm-1030mm |

|

Rotary table speed |

350rpm |

300rpm |

250rpm |

|

Worktable size |

Ø630mm |

Ø880mm |

Ø1100mm |

|

Max. table load |

Milling 2000Kg |

Milling 3000Kg |

Milling 4000Kg |

|

Turning 1000Kg |

Turning 1500Kg |

Turning 3000Kg |

|

|

Swing milling head (B axis) |

Standard |

Standard |

Standard |

|

Swing range (0=Vertical/180=Level) |

-15° to +180° |

-15° to +180° |

-15° to +180° |

|

B-axis rated speed |

50rpm |

50rpm |

50rpm |

|

Distance from vertical spindle nose to table |

162mm to 962mm |

162mm to 962mm |

160mm to 1160mm |

|

Electric spindle Max.speed |

12000rpm |

12000rpm |

10000rpm |

|

Power(S1-100%/S6-40%DC) |

34/42kW |

34/42kW |

42/58kW |

|

Power(S1-100%/S6-40%DC) |

32/192Nm |

32/192Nm |

215/350Nm |

|

Tool interface |

HSK-A63 |

HSK-A63 |

HSK-A100 |

|

Tool magazine capacity |

40T |

40T |

40T |

|

Max.tool diameter/length/weight |

Ø85mm/300mm/8Kg |

Ø85mm/300mm/8Kg |

φ135mm/300mm/12Kg |

|

Tool changing time(Tool to tool) |

4s |

4s |

4s |

|

Drilling(Normalizing medium carbon steel) |

Ø40mm |

Ø40mm |

Ø50mm |

|

Tapping(Normalizing medium carbon steel) |

M24 |

M24 |

M40 |

|

Spindle taper |

1:10 Taper |

1:10 Taper |

1:10 Taper |

|

Rapid traverse |

40m/min |

40m/min |

40m/min |

|

X/Y/Z positioning accuracy |

0.006mr |

0.006mr |

0.006mm |

|

X/Y/Z repeat positioning accuracy |

0.004mm |

0.004mm |

0.004mm |

|

B/C positioning aoouraoy |

8’’ |

8’’ |

8’’ |

|

B/C repeat positioning acouraoy |

4’’ |

4’’ |

4’’ |

|

Infrared probe |

Renishaw OMP60 |

Renishaw OMP60 |

Renishaw OMP60 |

|

Too setting gauge(Too measuring in machining area) |

Renishaw NC4F230 |

Renishaw NC4F230 |

Renishaw NC4F230 |

|

Machine height(Standard machine) |

3350mm |

3350mm |

3650mm |

|

Main body occupied area(L*W) |

4800mmx2930mm |

4800mmx2930mm |

5170mmx3340mm |

|

Tool magazine occupied area(L*W) |

1710mmx1350mm |

1710mmx1350mm |

1915mmx1400mm |

|

Chip conveyor occupied area(L*W) |

3070mmx1065mm |

3070mmx1065mm |

3120mmx1065mm |

|

Water tank occupied area(L*W) |

1785mmx1355mm |

1785mmx1355mm |

1785mmx1355mm |

|

Complete machine occupied area(excluding water tank) (L*W) |

5610mmx3600mm |

5610mmx3600mm |

5000mmx3750mm |

|

Machine weight |

20000Kg |

20000Kg |

30000Kg |

|

Control system |

Siemens 840Ds |

siemens840Ds |

siemens840Ds |