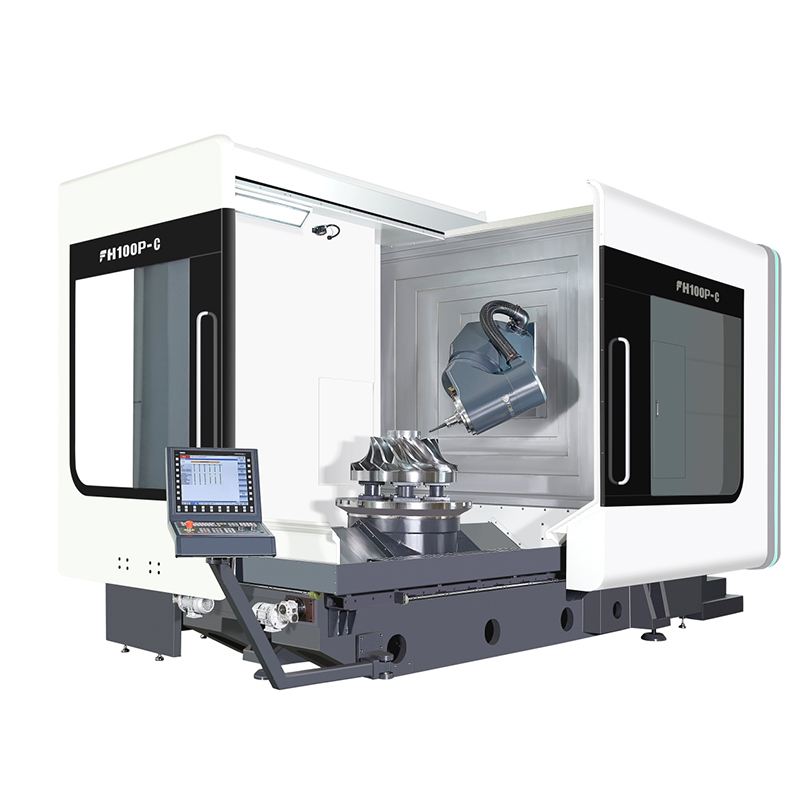

Five-axis Machining Center FH100P

Five-axis simultaneous machining center

XYZ linear axis hollow cooling screw drive

B\C rotary shaft DD direct drive transmission

Full closed loop absolute value measurement system

Main configuration

|

No |

Item |

Unit |

Qty |

|

1. |

FH mainframe mineral casting |

SET |

1 |

|

2. |

Siemens ONE control system |

SET |

1 |

|

3. |

Display: 21.5 inch touch display panel |

SET |

1 |

|

4. |

FH five-axis multi-function swing head (B-axis) |

SET |

1 |

|

5. |

FH-DGZX-28010/42B2 milling electric spindle(shielded turning function) |

PC |

1 |

|

6. |

X/Y/Z Axis Hollow Cooled Ball Screws |

PC |

3 |

|

7. |

Mill Direct Drive turntable (C-axis) |

SET |

1 |

|

8. |

B axis RCN8380 29 bits absolute encoder |

PC |

1 |

|

9. |

C axis RCN2580 28 bits absolute encoder |

PC |

1 |

|

10. |

INA Roller Linear Slides |

SET |

7 |

|

11. |

Spindle water cooling system |

SET |

1 |

|

12. |

Machine ring type water spray |

SET |

1 |

|

13. |

Five-axis head crescent type water spray, crescent type blow gas |

SET |

1 |

|

14. |

Front and side working door safety interlock system |

SET |

1 |

|

15. |

Waterproof working bin lighting |

PCS |

2 |

|

16. |

Hydraulic station |

SET |

1 |

|

17. |

Central centralized feed lubrication device |

SET |

1 |

|

18. |

Operation side cleaning water gun and air gun |

SET |

1 |

|

19. |

Cutting fluid system(CTS 25bar) |

SET |

1 |

|

20. |

Fully enclosed protective sheet metal |

SET |

1 |

|

21. |

Operation box |

SET |

1 |

|

22. |

Electrical box air conditioner |

SET |

1 |

|

23. |

Siemens electronic handwheel |

PC |

1 |

|

24. |

Foot-operated spindle knife release switch |

PC |

1 |

|

25. |

Machine tri-color light |

SET |

1 |

|

26. |

40PCS HSK-A100 tool magazine and servo automatic tool changing system |

SET |

1 |

|

27. |

X/Y/Z three-axis absolute value grating scale |

SET |

3 |

|

28. |

Spiral Chip rolling device and Rear Chip Conveyor+Chip car |

SET |

1 |

|

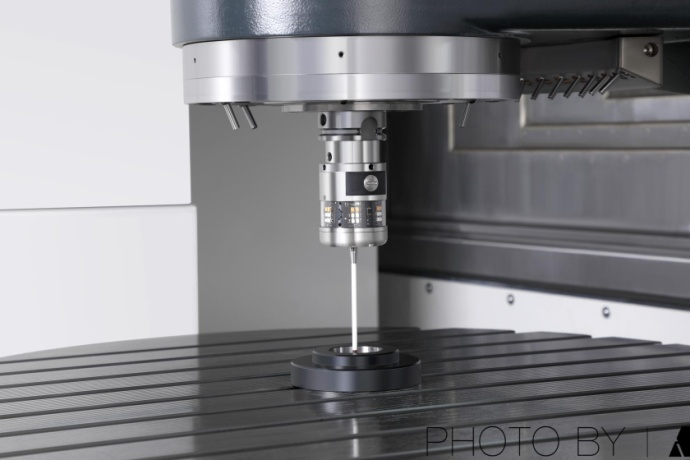

29. |

Renishaw OMP60 infrared probe device |

SET |

1 |

|

30. |

Renishaw NC4F230 laser tool setting device |

SET |

1 |

|

31. |

Foundation level pads and foundation bolts |

SET |

1 |

|

32. |

Technical manual |

SET |

1 |

Parameter

|

Model |

Unit |

FH100P |

|

Travel |

||

|

X axis travel |

mm |

1000 |

|

Y axis travel |

mm |

1150 |

|

Z axis travel |

mm |

1000 |

|

Distance from spindle nose to work table surface |

mm |

160-1160 |

|

Horizontal milling head |

mm |

30-1030 |

|

Feed/fast moving speed |

m/min |

40 |

|

Feed force |

KN |

10 |

|

Rotary table (C axis) |

||

|

Working table size |

mm |

Ø1100 |

|

Max.table load (mill) |

kg |

4000 |

|

Milling worktable max speed |

rpm |

100 |

|

Minimum split angle |

° |

0.001 |

|

Rated torque |

Nm |

1630 |

|

Maximum torque |

Nm |

2630 |

|

CNC swing milling head (B axis) |

||

|

Swing range(0=Vertical/180=Level) |

° |

-15~180 |

|

Fast moving and feeding speed |

rpm |

50 |

|

Minimum split angle |

° |

0.001 |

|

Rated torque |

Nm |

1050 |

|

Maximum torque |

Nm |

2130 |

|

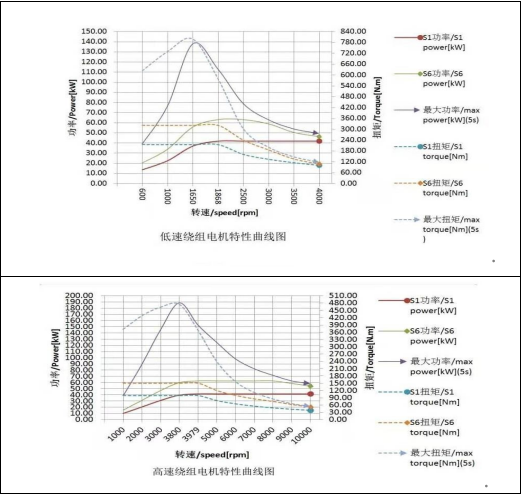

Spindle (milling and turning) |

||

|

Spindle speed |

rpm |

10000 |

|

Spindle power |

Kw |

42/58 |

|

Spindle torque |

Nm |

215/350 |

|

Spindle taper |

|

HSKA100 |

|

Tool magazine |

||

|

Tool interface |

|

HSKA100 |

|

Tool magazine capacity |

PCS |

40 |

|

Max.tool diameter/length/weight |

|

Ø135/300/12 |

|

Tool switch(Tool to tool) |

S |

4 |

|

Measuring device |

||

|

Infrared probe |

Rensishaw OMP60 |

|

|

Tool detection instrument in working processing area |

|

Rensishaw NC4F230 |

|

Position accuracy (ISO230-2 and VDI3441) |

||

|

X/Y/Z positioning accuracy |

mm |

0.006 |

|

X/Y/Z Repeat positioning accuracy |

mm |

0.004 |

|

B/C positioning accuracy |

|

8" |

|

B/C Repeat positioning accuracy |

|

4" |

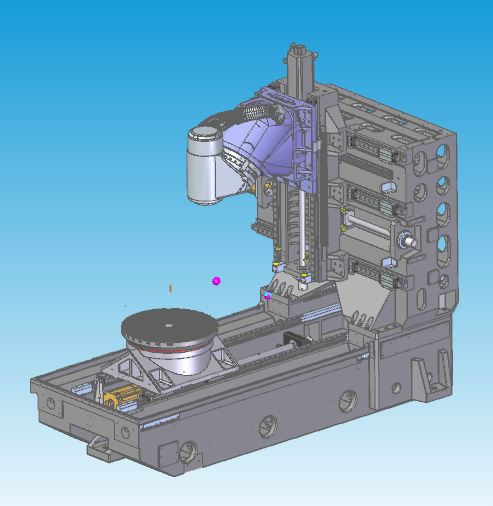

Main Machine Specifications | Optimum Rigid Structural Configuration

Design Features | Best Mechanical Wire Casting Analysis Design

◆The bed adopts a new mineral casting structure, and the moving parts adopt Meehanite grade high-grade cast iron

◆Tempering and natural aging treatment to eliminate internal stress

◆Structural natural frequency vibration eliminates material processing stress

◆The design of large-area and high-rigidity column on the whole wall can effectively improve the rigidity and static and dynamic precision

◆Three-axis hollow cooling screw drive

Electric spindle

Design Features

◆Independent research and development and production according to the characteristics of our own machines.

◆The taper hole of HSK-A100 is adopted in the FH100P model.

◆The external cooling system is used for circulating cooling, which effectively guarantees the application of the electric spindle.

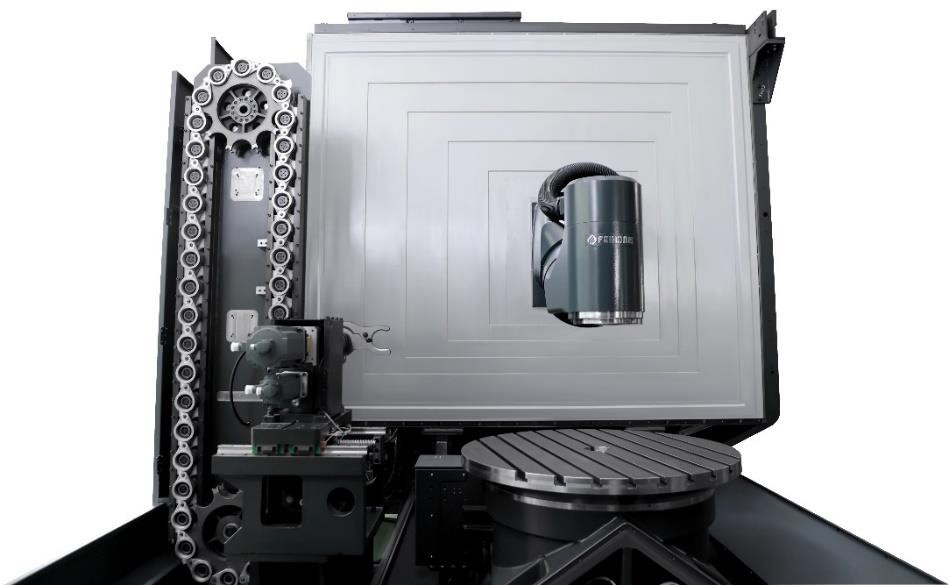

CNC swing milling head (B axis)

Design Features

◆ Built-in DD motor zero transmission chain no backlash design

◆ High acceleration characteristics

◆ The shortest span between the tool nose point of the spindle and the structural support point realizes the maximum rigidity of cutting

◆ Larger YRT bearings increase rigidity

◆ Equipped with HEIDENHAIN RCN8380 series absolute rotary encoder measurement system, fully closed-loop control to ensure the best accuracy

◆ B-axis cooling system design to reduce heat transfer

Rotary table (C axis)

Design Features

◆ Built-in DD motor zero transmission chain no backlash design

◆ High acceleration and deceleration response characteristics

◆ Larger YRT bearings increase rigidity

◆ Large rated driving torque, positioning and processing with table positioning and clamping device

◆ Meet the two processing needs of milling, reduce workpiece handling and improve product accuracy

◆ Equipped with HEIDENHAIN high-precision rotary encoder measurement system, fully closed-loop control to ensure the best accuracy

◆ Cooling system design to reduce heat transfer

Controller

Selection features

◆Select the control host NCU730.3B for five-axis linkage (see the function table for detailed function configuration of the system)

◆With RTCP function

◆Choose Siemens S120 driver with 3 times overload capacity and 1FT series motor with high motion characteristics

ATC system

Design Features

◆ Independent design and production.

◆ Tool selection and tool change use servo motor to control the terminal action, which is more stable and accurate.

◆ Combined with the tool management function of Siemens ONE, more efficient tool management.

Liftable tool setter

Design Features

◆ Equipped with Ransishaw NC4F230 non-contact laser tool setter for higher precision

◆ Automatic tool setting on machine, automatic update of tool compensation

◆ The tool setting device can be raised and lowered to save the space of the processing surface

◆ Fully sealed sheet metal design protects the tool setter from water and iron filings during processing

Infrared probe

Design Features

◆ Equipped with Ransishaw OMP60 optical touch probe

◆ On-machine workpiece alignment and size inspection, reduce manual inspection errors, improve product accuracy and processing efficiency

◆ 90% savings in on-machine assistance time

Exterior

The cover design of the FH series five-axis milling-turning compound machining center complies with the strict CE safety standards. The fully dense sheet metal prevents the operator from entering the working range by mistake during processing, and at the same time prevents the use of high-pressure cutting fluid or chip ejection from the machine. Except for In addition to the warning nameplate, the operation door is also equipped with a safety switch to prevent accidents during operation or maintenance. And has a large peep window, which is convenient for the operator to understand the operation and processing of the machine.

Clean

Use the telescopic cover and protective sheet metal to protect the chips generated during operation, avoid cutting splashes and cause damage to other mechanisms

Illumination

The working area is equipped with two LED lights, and the illuminance of the lighting is maintained above 800LUX, providing a suitable bright working environment for the operator.

Operability

The operation side is equipped with a split-type sliding door, which provides a large opening space, which is convenient for the workpiece to be freely loaded and unloaded from three directions using the crane.