Five-Axis Gantry Machining Center PM-U Series

Features

This series of products is a self-developed fixed beam five-axis gantry machining center with compact structure, excellent performance, high speed, high precision, high rigidity, etc. It is suitable for machining parts in a variety of industries such as aerospace, engineering machinery, rail transportation, precision molds, wind power, etc.

PM-U Series

It adopts high-speed and high-precision A/C double swing head and is equipped with a high-power and high-torque electric spindle, which has strong cutting ability.

A/C double swing head

It adopts imported high-precision, high-dynamic double swing heads and is equipped with a high-speed, high-torque electric spindle, meeting the high requirements for component precision, surface quality, and processing efficiency.

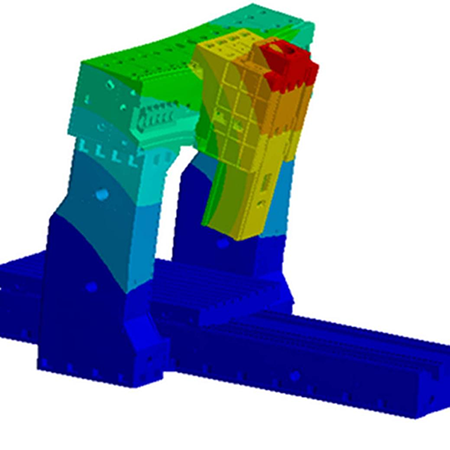

High rigidity structure optimized design

Finite element design methods are used to conduct static and modal analyses of various parts of the machine to further optimize the product structure and achieve high-rigidity and lightweight structural design.

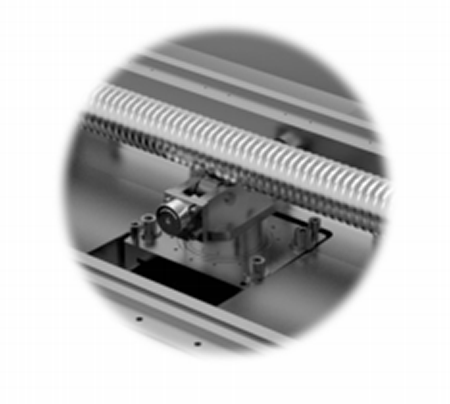

Screw auxiliary support structure

The long-travel lead screw is equipped with a floating support, which can effectively improve the limit speed of the lead screw and the stability of high-speed rotation.

Tool magazine

Various types of tool magazines, 24/32/40/60, are available to effectively shorten auxiliary machining hours.

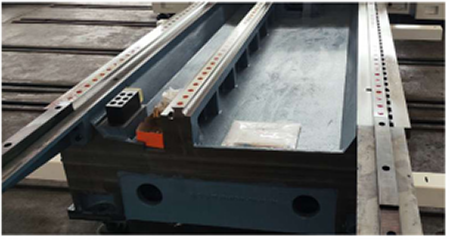

High rigidity support

The machine bed is equipped with three large-size guides, which provide sufficient support rigidity and precision retention.

Humanized safety design

The sheet metal labyrinth design at the bottom of the worktable prevents iron chips from entering the machine bed. The integrated chip removal trough fundamentally eliminates the problem of water leakage.

Technical Specifications

|

Item |

Unit |

RFPM3028U |

RFPM4028U |

RFPM6028U |

RFPM4033U |

|

Processing range |

|

|

|

|

|

|

X/Y/Z axis travel |

mm |

3200/3200/1000 |

4200/3200/1000 |

6200/3200/1000 |

4200/3700/1000 |

|

A/C axis rotation range |

° |

±105/±360 |

±105/±360 |

±105/±360 |

±105/±360 |

|

Gantry effective width |

mm |

2800 |

2800 |

2800 |

3300 |

|

Distance from spindle nose to worktable |

mm |

200-1200 |

200-1200 |

200-1200 |

200-1200 |

|

Worktable |

|

|

|

|

|

|

Worktable dimensions |

mm |

2000×3000 |

2000×4000 |

2000×6000 |

2500×4000 |

|

Worktable load bearing capacity |

t |

16 |

20 |

26 |

22 |

|

T-slot specifications |

mm |

28 |

28 |

28 |

28 |

|

Drive feed |

|

|

|

|

|

|

Max. feed speed X/Y/Z |

m/min |

12/12/12 |

12/12/12 |

12/12/12 |

10/10/10 |

|

Max. feed speed A/C |

rpm |

60 |

60 |

60 |

60 |

|

Rapid speed X/Y/Z |

m/min |

20/20/15 |

20/20/15 |

15/20/15 |

15/15/15 |

|

Rapid speed A/C |

rpm |

100 |

100 |

100 |

100 |

|

Spindle |

|

|

|

|

|

|

Driving method |

|

Electric spindle |

Electric spindle |

Electric spindle |

Electric spindle |

|

Max. spindle speed |

rpm |

7000 |

7000 |

7000 |

7000 |

|

Spindle power (S1/S6) |

Kw |

50/60 |

50/60 |

50/60 |

50/60 |

|

Spindle torque (S1/S6) |

Nm |

318/382 |

318/382 |

318/382 |

318/382 |

|

Spindle taper |

|

HSK-A100 |

HSK-A100 |

HSK-A100 |

HSK-A100 |

|

Tool magazine (optional) |

|

|

|

|

|

|

Tool magazine capacity |

T |

24 |

24 |

24 |

24 |

|

Tool holder type |

|

HSK-A100 |

HSK-A100 |

HSK-A100 |

HSK-A100 |

|

Max. tool diameter |

mm |

ф110/ф200 |

ф110/ф200 |

ф110/ф200 |

ф110/ф200 |

|

Max. tool length |

mm |

350 |

350 |

350 |

350 |

|

Max. tool weight |

kg |

20 |

20 |

20 |

20 |

|

Accuracy |

|

|

|

|

|

|

Positioning accuracy X/Y/Z |

mm |

0.018/0.018/0.014 |

0.020/0.018/0.014 |

0.028/0.018/0.014 |

0.020/0.018/0.014 |

|

Repeatability X/Y/Z |

mm |

0.012/0.012/0.010 |

0.012/0.012/0.010 |

0.018/0.012/0.010 |

0.012/0.012/0.010 |

|

Others |

|

|

|

|

|

|

Machine weight |

t |

57 |

63 |

75 |

70 |

|

Machine dimensions (L× W × H) |

cm |

910×670×650 |

1110×670×650 |

1510×670×650 |

1110×720×650 |

|

Item |

Unit |

RFPM6033U |

RFPM8033U |

RFPM6038U |

RFPM8038U |

|

Processing range |

|

|

|

|

|

|

X/Y/Z axis travel |

mm |

6200/3700/1000 |

8500/3700/1000 |

6200/4200/1000 |

8500/4200/1000 |

|

A/C axis rotation range |

° |

±105/±360 |

±105/±360 |

±105/±360 |

±105/±360 |

|

Gantry effective width |

mm |

3300 |

3300 |

3800 |

3800 |

|

Distance from spindle nose to worktable |

mm |

200-1200 |

200-1200 |

200-1200 |

200-1200 |

|

Worktable |

|

|

|

|

|

|

Worktable dimensions |

mm |

2500×6000 |

2500×8000 |

3000×6000 |

3000×8000 |

|

Worktable load bearing capacity |

t |

30 |

35 |

35 |

40 |

|

T-slot specifications |

mm |

28 |

28 |

28 |

28 |

|

Drive feed |

|

|

|

|

|

|

Max. feed speed X/Y/Z |

m/min |

8/10/10 |

8/10/10 |

8/10/10 |

8/10/10 |

|

Max. feed speed A/C |

rpm |

60 |

60 |

60 |

60 |

|

Rapid speed X/Y/Z |

m/min |

12/15/15 |

10/15/15 |

12/15/15 |

10/15/15 |

|

Rapid speed A/C |

rpm |

100 |

100 |

100 |

100 |

|

Spindle |

|

|

|

|

|

|

Driving method |

|

Electric spindle |

Electric spindle |

Electric spindle |

Electric spindle |

|

Max. spindle speed |

rpm |

7000 |

7000 |

7000 |

7000 |

|

Spindle power (S1/S6-40%) |

Kw |

50/60 |

50/60 |

50/60 |

50/60 |

|

Spindle torque (S1/S6-40%) |

Nm |

318/382 |

318/382 |

318/382 |

318/382 |

|

Spindle taper |

|

HSK-A100 |

HSK-A100 |

HSK-A100 |

HSK-A100 |

|

Tool magazine (optional) |

|

|

|

|

|

|

Tool magazine capacity |

T |

24 |

24 |

24 |

24 |

|

Tool holder type |

|

HSK-A100 |

HSK-A100 |

HSK-A100 |

HSK-A100 |

|

Max. tool diameter |

mm |

ф110/ф200 |

ф110/ф200 |

ф110/ф200 |

ф110/ф200 |

|

Max. tool length |

mm |

350 |

350 |

350 |

350 |

|

Max. tool weight |

kg |

20 |

20 |

20 |

20 |

|

Accuracy |

|

|

|

|

|

|

Positioning accuracy X/Y/Z |

mm |

0.028/0.018/0.014 |

0.032/0.018/0.014 |

0.028/0.024/0.014 |

0.032/0.024/0.014 |

|

Repeatability X/Y/Z |

mm |

0.018/0.012/0.010 |

0.020/0.012/0.010 |

0.018/0.016/0.010 |

0.020/0.016/0.010 |

|

Others |

|

|

|

|

|

|

Machine weight |

t |

84 |

100 |

94 |

115 |

|

Machine dimensions (L× W × H) |

cm |

1550×720×650 |

2050×720×650 |

1550×800×650 |

2050×800×650 |