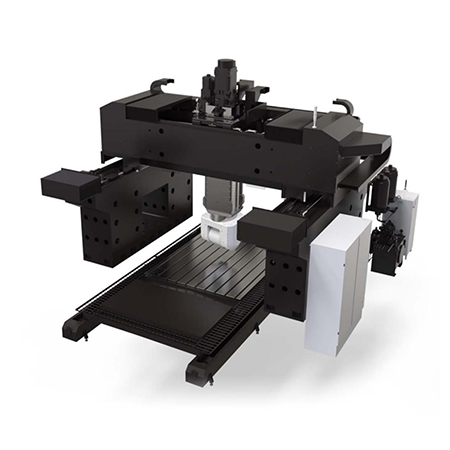

Five-Axis Gantry Machining Center PM-GUN Series

Features

This series of products is a self-developed high-rigidity bridge-type five-axis gantry machining center. It adopts a box-in-box symmetrical beam structure to meet the processing needs of high-torque, high-rigidity, and high-efficiency titanium alloy, high-temperature alloy and other parts.

PM-GUN Series

The high-rigidity box-in-box crossbeam structure is equipped with a high-power and high-torque A/C double-swing head, which has strong cutting ability and precision stability.

Crossbeam

It adopts a box-in-box symmetrical crossbeam structure design, a large-span four-track configuration, and the slide block is placed in the middle of the crossbeam, so that the whole machine is evenly stressed, which greatly improves the life of the guide and the accuracy retention.

A/C double swing head

Imported high-precision, high-dynamic double swing head, equipped with high-speed and high-torque electric spindle, can meet the processing requirements of high efficiency and strong cutting of parts.

Dual motor drive

The long-travel drive adopts a gear rack dual-motor anti-backlash structure, which has the characteristics of strong transmission rigidity, high precision and easy maintenance.

Tool magazine

Various types of tool magazines, 24/32/40/60, are available to effectively shorten auxiliary machining hours.

Fully closed loop position detection

The position detection of the X, Y, and Z axes of the machine tool adopts imported precision optical scales, and the A and C axes adopt high-precision angle encoders to achieve full closed-loop position feedback to realize full closed-loop control of the machine, thereby ensuring the position accuracy of the machine.

Technical Specifications

|

Item |

Unit |

RFPM2040GUN |

RFPM2060GUN |

RFPM2540GUN |

RFPM2560GUN |

|

Processing range |

|

|

|

|

|

|

X/Y/Z axis travel |

mm |

4000/2200/1000 |

6000/2200/1000 |

4000/2700/1000 |

6000/2700/1000 |

|

A/C axis rotation range |

° |

±110/±360 |

±110/±360 |

±110/±360 |

±110/±360 |

|

Gantry effective width |

mm |

3200 |

3200 |

3700 |

3700 |

|

Distance from spindle nose to worktable |

mm |

100-1100 |

100-1100 |

100-1100 |

100-1100 |

|

Worktable |

|

|

|

|

|

|

Worktable dimensions |

mm |

2000×4000 |

2000×6000 |

2500×4000 |

2500×6000 |

|

Worktable load bearing capacity |

t/m² |

5 |

5 |

5 |

5 |

|

T-slot specifications |

mm |

28 |

28 |

28 |

28 |

|

Drive feed |

|

|

|

|

|

|

Max. feed speed X/Y/Z |

m/min |

15/15/15 |

15/15/15 |

15/15/15 |

15/15/15 |

|

Max. feed speed A/C |

rpm |

60 |

60 |

60 |

60 |

|

Rapid speed X/Y/Z |

m/min |

20/20/20 |

20/20/20 |

20/20/20 |

20/20/20 |

|

Rapid speed A/C |

rpm |

100 |

100 |

100 |

100 |

|

Spindle |

|

|

|

|

|

|

Driving method |

|

Electric spindle |

Electric spindle |

Electric spindle |

Electric spindle |

|

Max. spindle speed |

rpm |

7000 |

7000 |

7000 |

7000 |

|

Spindle power (S1/S6-40%) |

Kw |

50/60 |

50/60 |

50/60 |

50/60 |

|

Spindle torque (S1/S6-40%) |

Nm |

318/382 |

318/382 |

318/382 |

318/382 |

|

Spindle taper |

|

HSK-A100 |

HSK-A100 |

HSK-A100 |

HSK-A100 |

|

Tool magazine (optional) |

|

|

|

|

|

|

Tool magazine capacity |

T |

24 |

24 |

24 |

24 |

|

Tool holder type |

|

HSK-A100 |

HSK-A100 |

HSK-A100 |

HSK-A100 |

|

Max. tool diameter |

mm |

ф125/ф170 |

ф125/ф170 |

ф125/ф170 |

ф125/ф170 |

|

Max. tool length |

mm |

300 |

300 |

300 |

300 |

|

Max. tool weight |

kg |

15 |

15 |

15 |

15 |

|

Accuracy |

|

|

|

|

|

|

Positioning accuracy X/Y/Z |

mm |

0.020/0.012/0.014 |

0.028/0.012/0.014 |

0.020/0.018/0.014 |

0.028/0.018/0.014 |

|

Repeatability X/Y/Z |

mm |

0.012/0.010/0.010 |

0.018/0.010/0.010 |

0.012/0.012/0.010 |

0.018/0.012/0.010 |

|

Others |

|

|

|

|

|

|

Machine weight |

t |

67 |

75 |

70 |

80 |

|

Machine dimensions (L× W × H) |

cm |

900×670×600 |

1100×670×600 |

900×720×600 |

1100×720×600 |

|

Item |

Unit |

RFPM3040GUN |

RFPM3060GUN |

RFPM3560GUN |

RFPM3580GUN |

|

Processing range |

|

|

|

|

|

|

X/Y/Z axis travel |

mm |

4000/3200/1000 |

6000/3200/1000 |

6000/3700/1000 |

8000/3700/1000 |

|

A/C axis rotation range |

° |

±110/±360 |

±110/±360 |

±105/±360 |

±105/±360 |

|

Gantry effective width |

mm |

4200 |

4200 |

4700 |

4700 |

|

Distance from spindle nose to worktable |

mm |

100-1100 |

100-1100 |

100-1100 |

100-1100 |

|

Worktable |

|

|

|

|

|

|

Worktable dimensions |

mm |

3000×4000 |

3000×6000 |

3500×6000 |

3500×8000 |

|

Worktable load bearing capacity |

t/m² |

5 |

5 |

5 |

5 |

|

T-slot specifications |

mm |

28 |

28 |

28 |

28 |

|

Drive feed |

|

|

|

|

|

|

Max. feed speed X/Y/Z |

m/min |

15/15/15 |

15/15/15 |

15/15/15 |

15/15/15 |

|

Max. feed speed A/C |

rpm |

60 |

60 |

60 |

60 |

|

Rapid speed X/Y/Z |

m/min |

20/20/20 |

20/20/20 |

20/20/20 |

20/20/20 |

|

Rapid speed A/C |

rpm |

100 |

100 |

100 |

100 |

|

Spindle |

|

|

|

|

|

|

Driving method |

|

Electric spindle |

Electric spindle |

Electric spindle |

Electric spindle |

|

Max. spindle speed |

rpm |

7000 |

7000 |

7000 |

7000 |

|

Spindle power (S1/S6-40%) |

Kw |

50/60 |

50/60 |

50/60 |

50/60 |

|

Spindle torque (S1/S6-40%) |

Nm |

318/382 |

318/382 |

318/382 |

318/382 |

|

Spindle taper |

|

HSK-A100 |

HSK-A100 |

HSK-A100 |

HSK-A100 |

|

Tool magazine (optional) |

|

|

|

|

|

|

Tool magazine capacity |

T |

24 |

24 |

24 |

24 |

|

Tool holder type |

|

HSK-A100 |

HSK-A100 |

HSK-A100 |

HSK-A100 |

|

Max. tool diameter |

mm |

ф125/ф170 |

ф125/ф170 |

ф125/ф170 |

ф125/ф170 |

|

Max. tool length |

mm |

300 |

300 |

300 |

300 |

|

Max. tool weight |

kg |

15 |

15 |

15 |

15 |

|

Accuracy |

|

|

|

|

|

|

Positioning accuracy X/Y/Z |

mm |

0.020/0.018/0.014 |

0.028/0.018/0.014 |

0.028/0.024/0.014 |

0.032/0.024/0.014 |

|

Repeatability X/Y/Z |

mm |

0.012/0.012/0.010 |

0.018/0.012/0.010 |

0.020/0.016/0.010 |

0.020/0.016/0.010 |

|

Others |

|

|

|

|

|

|

Machine weight |

t |

75 |

85 |

90 |

105 |

|

Machine dimensions (L× W × H) |

cm |

900×770×600 |

1100×770×600 |

1100×820×600 |

1300×820×600 |