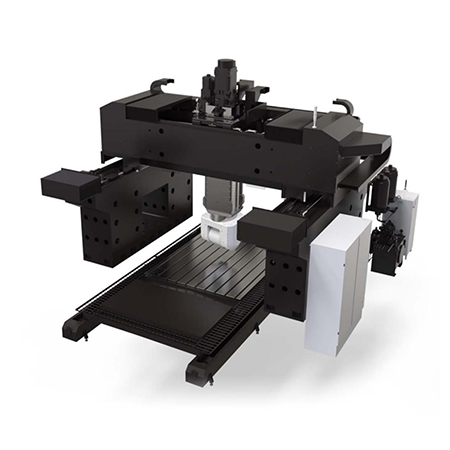

Five-axis gantry machining center PM-GU series

Features

This series of products is an elevated bridge type five-axis gantry machining center independently developed by Rifa Precision Machinery. The product processing has the characteristics of high dynamics, high efficiency, high stability, etc. It is suitable for complex surface processing of parts with high precision requirements in industries such as aerospace, precision molds, and wind power.

PM-GU Series

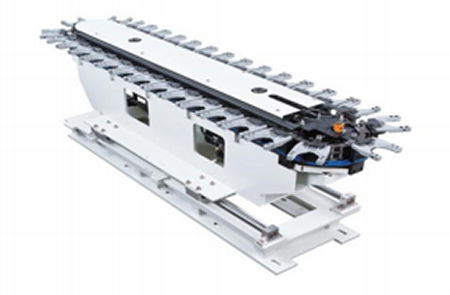

It adopts high-performance A/C double swing head, which has the ability to process complex spatial surfaces at high speed, high precision and high efficiency.

A/C Double Swing Head

The double swing head is configured to achieve a larger working space, meet the processing requirements of complex curved surface parts, and improve processing accuracy and product quality.

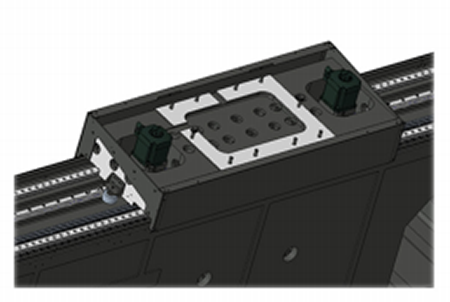

Crossbeam

The crossbeam is optimized through finite element analysis and designed to be as lightweight as possible while ensuring rigidity, thereby improving the high-speed processing performance of the product.

Bed Frame

The machine bed adopts a modular design, and the stroke can be expanded according to customer needs to meet more processing requirements.

Tool magazine

Various types of tool magazines, 24/32/40/60, are available to effectively shorten auxiliary machining hours.

Electric spindle

Optional 15000~24000rpm, high torque, high speed electric spindle.

Technical Specifications

|

Item |

Unit |

RFPM2040GU |

RFPM2060GU |

RFPM2540GU |

RFPM2560GU |

|

Processing range |

|

|

|

|

|

|

X/Y/Z axis travel |

mm |

4000/2200/1000 |

6000/2200/1000 |

4000/2700/1000 |

6000/2700/1000 |

|

A/C axis rotation range |

° |

±105/±360 |

±105/±360 |

±105/±360 |

±105/±360 |

|

Gantry effective width |

mm |

3200 |

3200 |

3700 |

3700 |

|

Distance from spindle nose to worktable |

mm |

100-1100 |

100-1100 |

100-1100 |

100-1100 |

|

Worktable |

|

|

|

|

|

|

Worktable dimensions |

mm |

2000×4000 |

2000×6000 |

2500×4000 |

2500×6000 |

|

Worktable load bearing capacity |

t/m2 |

5 |

5 |

5 |

5 |

|

T-slot specifications |

mm |

28 |

28 |

28 |

28 |

|

Drive feed |

|

|

|

|

|

|

Max. feed speed X/Y/Z |

m/min |

30/30/30 |

30/30/30 |

30/30/30 |

30/30/30 |

|

Max. feed speed A/C |

rpm |

60 |

60 |

60 |

60 |

|

Rapid speed X/Y/Z |

m/min |

30/30/30 |

30/30/30 |

30/30/30 |

30/30/30 |

|

Rapid speed A/C |

rpm |

100 |

100 |

100 |

100 |

|

Spindle |

|

|

|

|

|

|

Driving method |

|

Electric spindle |

Electric spindle |

Electric spindle |

Electric spindle |

|

Max. spindle speed |

rpm |

24000 |

24000 |

24000 |

24000 |

|

Spindle power (S1/S6-40%) |

Kw |

43/52 |

43/52 |

43/52 |

43/52 |

|

Spindle torque (S1/S6-40%) |

Nm |

67/83 |

67/83 |

67/83 |

67/83 |

|

Spindle taper |

|

HSK-A63 |

HSK-A63 |

HSK-A63 |

HSK-A63 |

|

Tool magazine (optional) |

|

|

|

|

|

|

Tool magazine capacity |

T |

24 |

24 |

24 |

24 |

|

Tool holder type |

|

HSK-A63 |

HSK-A63 |

HSK-A63 |

HSK-A63 |

|

Max. tool diameter |

mm |

ф75/ф120 |

ф75/ф120 |

ф75/ф120 |

ф75/ф120 |

|

Max. tool length |

mm |

270 |

270 |

270 |

270 |

|

Max. tool weight |

kg |

6 |

6 |

6 |

6 |

|

Accuracy |

|

|

|

|

|

|

Positioning accuracy X/Y/Z |

mm |

0.020/0.012/0.014 |

0.028/0.012/0.014 |

0.020/0.018/0.014 |

0.028/0.018/0.014 |

|

Repeatability X/Y/Z |

mm |

0.012/0.010/0.010 |

0.018/0.010/0.010 |

0.012/0.012/0.010 |

0.018/0.012/0.010 |

|

Others |

|

|

|

|

|

|

Machine weight |

t |

62 |

70 |

67 |

77 |

|

Machine dimensions (L× W × H) |

cm |

1000×650×600 |

1200×650×600 |

1000×700×600 |

1200×700×600 |

|

Item |

Unit |

RFPM3040GU |

RFPM3060GU |

RFPM3560GU |

RFPM3580GU |

|

Processing range |

|

|

|

|

|

|

X/Y/Z axis travel |

mm |

4000/3200/1000 |

6000/3200/1000 |

6000/3700/1000 |

8000/3700/1000 |

|

A/C axis rotation range |

° |

±105/±360 |

±105/±360 |

±105/±360 |

±105/±360 |

|

Gantry effective width |

mm |

4200 |

4200 |

4700 |

4700 |

|

Distance from spindle nose to worktable |

mm |

100-1100 |

100-1100 |

100-1100 |

100-1100 |

|

Worktable |

|

|

|

|

|

|

Worktable dimensions |

mm |

3000×4000 |

3000×6000 |

3500×6000 |

3500×8000 |

|

Worktable load bearing capacity |

t/m2 |

5 |

5 |

5 |

5 |

|

T-slot specifications |

mm |

28 |

28 |

28 |

28 |

|

Drive feed |

|

|

|

|

|

|

Max. feed speed X/Y/Z |

m/min |

30/30/30 |

30/30/30 |

30/30/30 |

30/30/30 |

|

Max. feed speed A/C |

rpm |

60 |

60 |

60 |

60 |

|

Rapid speed X/Y/Z |

m/min |

30/30/30 |

30/30/30 |

30/30/30 |

30/30/30 |

|

Rapid speed A/C |

rpm |

100 |

100 |

100 |

100 |

|

Spindle |

|

|

|

|

|

|

Driving method |

|

Electric spindle |

Electric spindle |

Electric spindle |

Electric spindle |

|

Max. spindle speed |

rpm |

24000 |

24000 |

24000 |

24000 |

|

Spindle power (S1/S6-40%) |

Kw |

43/52 |

43/52 |

43/52 |

43/52 |

|

Spindle torque (S1/S6-40%) |

Nm |

67/83 |

67/83 |

67/83 |

67/83 |

|

Spindle taper |

|

HSK-A63 |

HSK-A63 |

HSK-A63 |

HSK-A63 |

|

Tool magazine (optional) |

|

|

|

|

|

|

Tool magazine capacity |

T |

24 |

24 |

24 |

24 |

|

Tool holder type |

|

HSK-A63 |

HSK-A63 |

HSK-A63 |

HSK-A63 |

|

Max. tool diameter |

mm |

ф75/ф120 |

ф75/ф120 |

ф75/ф120 |

ф75/ф120 |

|

Max. tool length |

mm |

270 |

270 |

270 |

270 |

|

Max. tool weight |

kg |

6 |

6 |

6 |

6 |

|

Accuracy |

|

|

|

|

|

|

Positioning accuracy X/Y/Z |

mm |

0.020/0.018/0.014 |

0.028/0.018/0.014 |

0.028/0.024/0.014 |

0.032/0.024/0.014 |

|

Repeatability X/Y/Z |

mm |

0.012/0.012/0.010 |

0.018/0.012/0.010 |

0.020/0.016/0.010 |

0.020/0.016/0.010 |

|

Others |

|

|

|

|

|

|

Machine weight |

t |

70 |

80 |

85 |

100 |

|

Machine dimensions (L× W × H) |

cm |

1000×750×600 |

1200×750×600 |

1200×800×600 |

1400×800×600 |