Five-axis Gantry Machining Center GT Series

Features

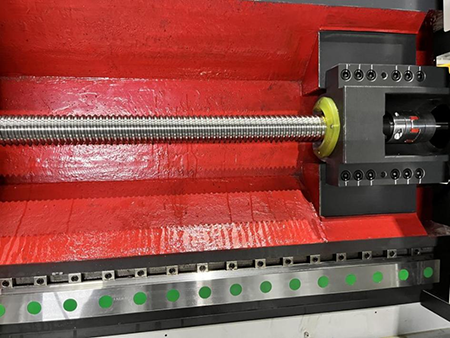

The three-axis adopts internationally renowned brand roller guide rails, which have strong rigidity and excellent dynamic accuracy; The three-axis transmission adopts Taiwan made large-diameter grinding ball screw, which has a compact structure, smooth movement, low thermal elongation, and high accuracy. The screw support forms a stable high rigidity mechanical transmission system; High precision spindle can provide constant and reliable lubrication for spindle bearings; The standard spindle oil cooling system keeps the spindle in a stable working state for a long time. The main components of the machine tool, including the base, workbench, column, spindle box, and saddle, are all analyzed using FEA finite element analysis, which has the characteristics of design optimization, lightweight mechanism, and high rigidity.

The distance between the spindle center and the guide rail surface is short, and the flipping torque is small, which improves the stability of processing. Adopting resin sand molding, high-strength and high-quality cast iron, with a complete heat treatment process to eliminate residual stress, and the contact surface undergoes a precise manual scraping program to ensure the optimal structural rigidity of the entire machine, ensuring the optimal structural rigidity of the entire machine. Multiple product lines with complete specifications, paired with a highly elastic automated exchange head library and a vertical and horizontal tool changing system, providing automated, efficient, and highly productive processing performance. The modular spindle design provides different cutting characteristics and meets diverse machining needs. The Y-axis adopts an ultra-high rigidity roller type linear slide rail, which combines the heavy cutting rigidity of the hard rail with the fast movement and low wear of the linear slide rail, greatly improving rigidity and control.

Technical Specifications

|

Item |

Unit |

GT-2720-5X |

GT-3022-5X |

GT-4022-5X |

GT-4025-5X |

GT-6025-5X |

|

X/Y/Z Travel |

mm |

2700/2000/900 |

3000/2200/1000 |

4000/2200/1000 |

4000/2500/1000 |

6000/2500/1000 |

|

A Axis |

° |

110 |

±110 |

±110 |

±110 |

±110 |

|

C Axis |

° |

270 |

±270 |

±270 |

±270 |

±270 |

|

Worktable size |

mm |

2800×1600 |

3200×2000 |

4200×2000 |

4200×2200 |

6200×2200 |

|

Maximum load of worktable |

kg/m² |

10000(average load) |

12000(average load) |

15000(average load) |

18000(average load) |

20000(average load) |

|

Distance from spindle nose to worktable |

mm |

350-1250 |

350-1350 |

350-1350 |

350-1350 |

350-1350 |

|

Distance between two columns |

mm |

2000 |

2200 |

2200 |

2500 |

2500 |

|

Spindle taper |

/ |

HSK-A63 |

HSK-A63 |

HSK-A63 |

HSK-A63, |

HSK-A63 |

|

Spindle speed |

/ |

18000 |

18000 |

18000 |

18000 |

18000 |

|

Spindle power |

kw |

30/38 |

30/38 |

30/38 |

30/38 |

30/38 |

|

GOO fast feed |

mm/min |

15000/15000/15000 |

15000/15000/15000 |

15000/15000/15000 |

15000/15000/15000 |

15000/15000/15000 |

|

G01 cutting feed |

mm/min |

1-10000 |

1-10000 |

1-10000 |

1-10000 |

1-10000 |

|

Machine weight |

kg |

38500 |

42000 |

45000 |

48000 |

55000 |

|

Cutting fluid capacity |

L |

400 |

500 |

500 |

500 |

500 |

|

Lubricating oil tank capacity |

L |

4 |

4 |

4 |

4 |

4 |

|

Electricity requirement |

KVA |

50 |

60 |

80 |

60 |

80 |

|

Air pressure requirements |

kg/cm² |

5-8 |

5-8 |

5-8 |

5-8 |

5-8 |

|

Tool magazine form |

/ |

Umbrella Type/ |

Umbrella Type/ |

Umbrella Type/ |

Umbrella Type/ |

Umbrella Type/ |

|

Tool magazine specifications |

/ |

HSK-A63, |

HSK-A63, |

HSK-A63, |

HSK-A63, |

HSK-A63 |

|

Tool magazine capacity |

/ |

24,Optional:40/60 |

24,Optional:40/60 |

24,Optional:40/60 |

24,Optional:40/60 |

24,Optional:40/60 |

|

Max. tool size (diameter/length) |

mm |

φ78/300 |

φ78/300 |

φ78/300 |

φ78/300 |

φ78/300 |

|

Max.tool weight |

kg |

8(OP:18) |

8(OP:18) |

8(OP:18) |

8(OP:18) |

8(OP:18) |

|

Positioning accuracy |

mm |

0.008/300 |

0.008/300 |

0.008/300 |

0.008/300 |

0.008/300 |

|

Repeat positioning accuracy |

mm |

0.005/300 |

0.005/300 |

0.005/300 |

0.005/300 |

0.005/300 |

|

Machine size |

mm |

7200*4000*4300 |

8400*3800*4300 |

10600*3800*4300 |

10600*4400*4300 |

15600*4400*4300 |

|

Shortest tool change time (T-T) |

s |

1.55 |

1.55 |

1.55 |

1.55 |

1.55 |

Configuration Introduction

(1)FANUC Operating

The panel is intuitive and precise surface, easy to operate.

(2)Linear Guide

Linear guides has zero clearance, uniform surface texture and higher positioning accuracy.

(3)Spindle

A2-6/A2-8/A2-11/A2-15 spindles can be selected according to different models.

(4)Electrical Cabinet

Control various movements of the machine and monitor the operating status.

(5)Tool Magazine

Significantly shortens processing times and reduces tool change times.