Five-axis Gantry Machining Center GF Series

Features

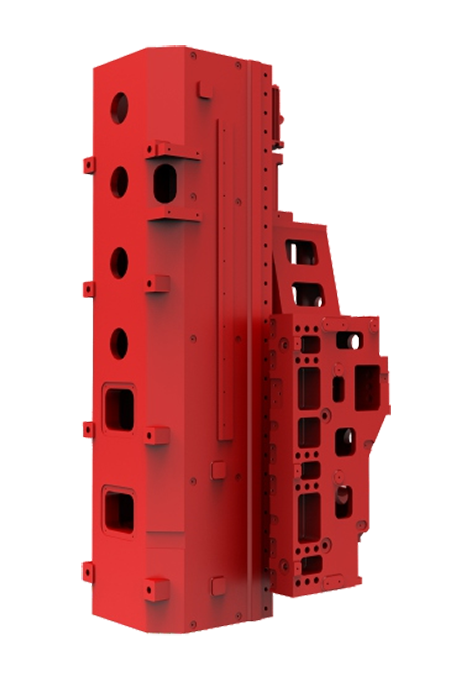

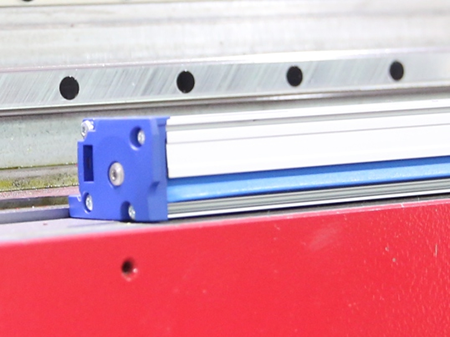

Tilted Design Of The X-axis

The mounting platform height of different X-axis linear guide rails ensures high rigidity and realizes high-speed and high-precision positioning

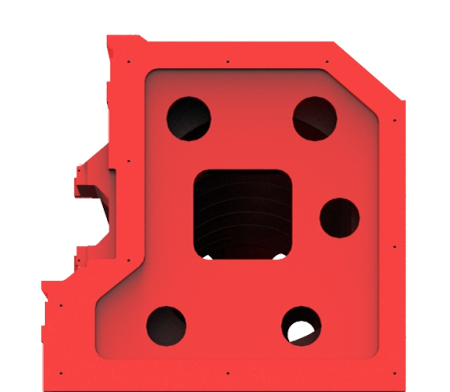

Special U-shaped Saddle Design

The head is designed with high rigidity headstock,which is clamped by U-shaped saddle through guide rails on both sides to ensure the high rigidity of Z-axis extension machining

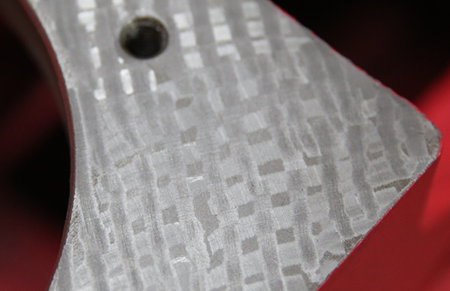

The Joint Surface Of The Whole Machine Structure Is Precision Shoveled

Its contact area is more than 90% to ensure the geometric accuracy of the whole machine

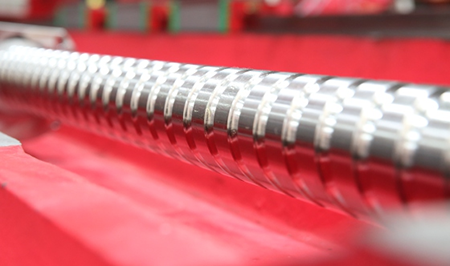

Ultra Stable Accuracy

The screw rod adopts the installation mode of fixed pre-tension at both ends and scraping at the casting joints to ensure the ultra-high and ultra-stable precision of the machine tool under large travel.

Integrated Gantry And Base

Column beam integrated design, improve the rigidity of the machine and processing stability.

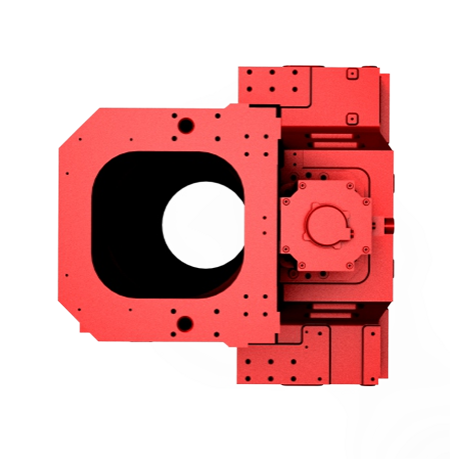

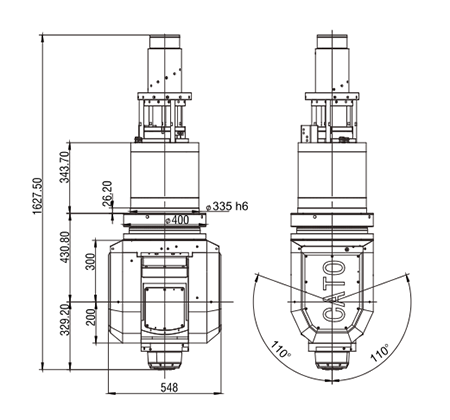

F1 Fork Type Synchronous Two-axis Milling Head

The symmetrical cross structure has higher structural rigidity and vibration suppression than the same level models.

The B/C axis uses a direct drive motor and a high-response hydraulic brake system, which has higher precision, zero backlash and zero wear.

The water-cooled circuit design and the spindle is equipped with a central water outlet as standard, which can effectively suppress temperature rise changes and ensure higher precision.

Optional Configuration

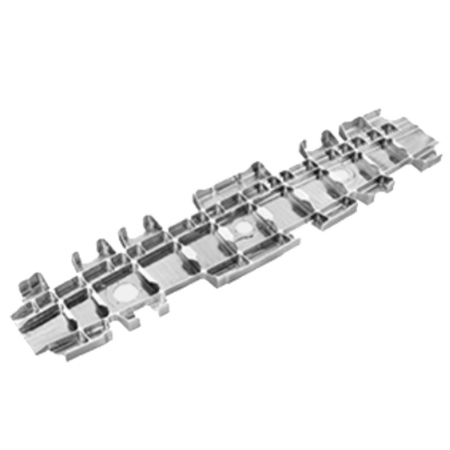

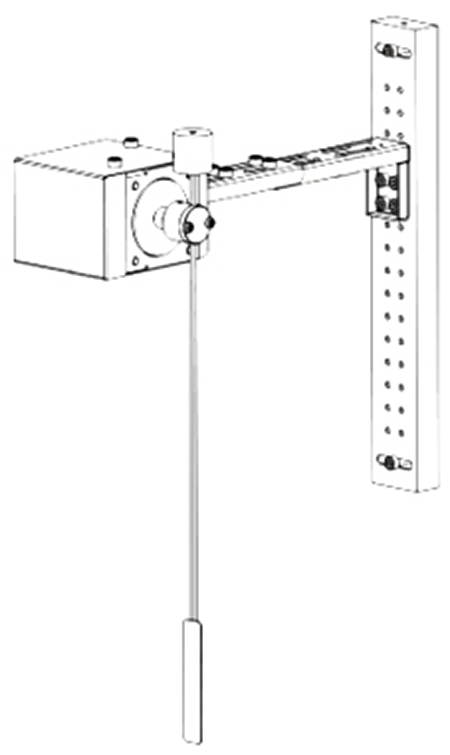

Broken Tool Detection In The Magazine

The detection unit is installed in the tool library, and the detection process and the processing process are carried out simultaneously, without affecting the processing beat.

Axial Optional Scales

The measured output signal is digital pulse, which has the characteristics of large detection range, high detection accuracy and fast response speed.

Online Detection System

Reduce tool setting and workpiece alignment time, and save 90% auxiliary time.

Reduce the waste products caused by the alignment error of tool setting and workpiece, and improve the yield.

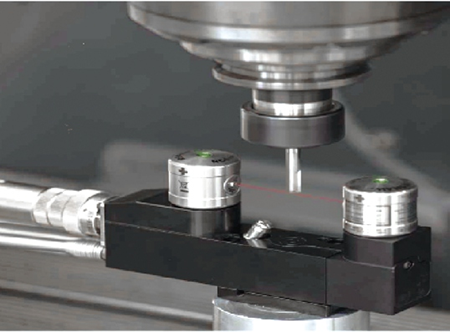

Laser Tool Setting Instrument

Fast and accurate detection of tool size to ensure long-term use without wear

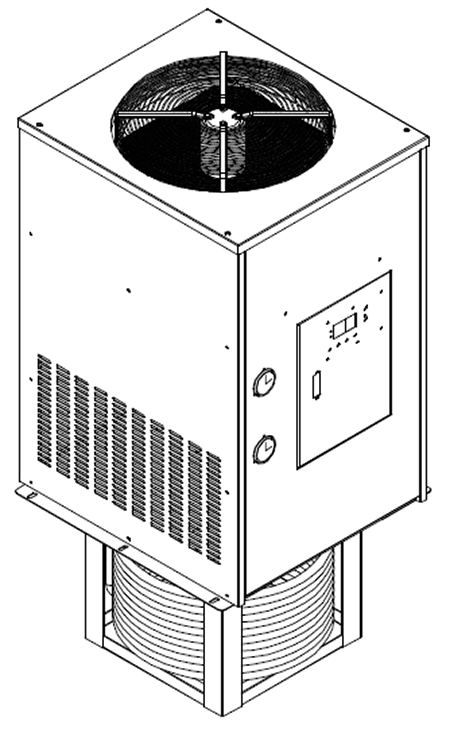

Cutting Fluid Cooling Device

The thermal displacement of fifixture and workpiece caused by the temperature rise of cutting flfluid will affect the machining accuracy.

The system can ensure the temperature rise of cutting flfluid within 3-5℃

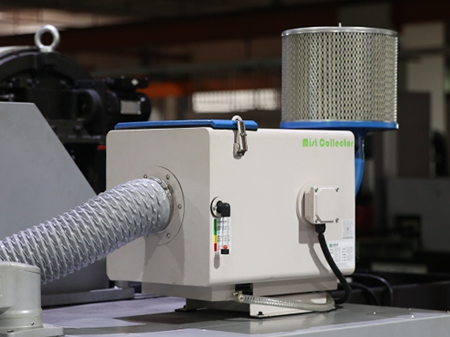

Oil Mist Gathering System

High puri cation rate, stable operation, silent noise oor.Effectively lter the water-soluble air and oil mist smoke in the workshop and deeply purify the air.

Technical Specifications

|

Project |

GF2020-5X |

GF3020-5X |

GF4020-5X |

|

|

Travel |

X/Y/Z axis travel |

2000×2000×800mm |

3000×2000×800mm |

4000×3000×1000mm |

|

Spindle nose to table center |

90-890mm |

80-880mm |

-100-900mm |

|

|

Table |

Table size |

2000×1100mm |

3000×1200mm |

4000×2000mm |

|

Max.table load |

2000Kg |

2500kg |

20000kg |

|

|

Spindle |

Spindle taper |

HSK-A63 |

HSK-A63 |

HSK-A100 |

|

Max.spindle speed |

18000rmp |

18000rmp |

8000rmp |

|

|

Spindle motor power |

30/33.5KW |

30/33.5KW |

70/75KW |

|

|

Spindle motor torque |

72/85Nm |

72/85Nm |

350/450Nm |

|

|

Feed rate |

Rapid speed of X/Y/Z axis |

36/30/30 |

30/30/30 |

15/15/10 |

|

Cutting feed |

1-12000 |

1-12000 |

1-10000 |

|

|

ATC |

Number of tool |

24T |

24T |

24T |

|

Maximum tool length |

400mm |

400mm |

400mm |

|

|

Maximum tool diameter |

120mm |

120mm |

250mm |

|

|

Maximum tool weight |

8kg |

8kg |

15kg |

|

|

Tool changetime (tool to tool) |

4.5S |

4.5S |

5S |

|

|

Three axis |

X-axis guide |

45/4 Roller |

45/5 Roller |

45/4 Roller |

|

Y-axis guide |

55/2 Roller |

55/2 Roller |

65 Roller |

|

|

Z-axis guide |

55/3 Roller |

55/3 Roller |

65 Roller |

|

|

X-axis screw |

φ50×16 |

φ63×16 |

φ80×20 |

|

|

Y-axis screw |

φ50×16 |

φ50×16 |

φ63×16 |

|

|

Z-axis screw |

φ50×12 |

φ50×12 |

φ63×16 |

|

|

Precision |

Positioning precision |

±0.005/300mm |

±0.005/300mm |

±0.005/300mm |

|

Repeating positioning precision |

±0.003/300mm ±0.003/300mm |

±0.003/300mm |

||

|

Power |

Power requirement |

Three-phase 380V±10%,50Hz±1%Three-phase 380V±10%,50Hz±1% |

Three-phase 380V±10%,50Hz±1% |

|

|

Air pressure |

≥6kg/c ≥6kg/c |

≥6kg/c |

||

|

Air flowrate |

≥0.5mm³/min ≥0.5mm³/min |

≥0.5mm³/min |

||

|

Machine size |

Machine weight |

20T 22T |

50T |

|

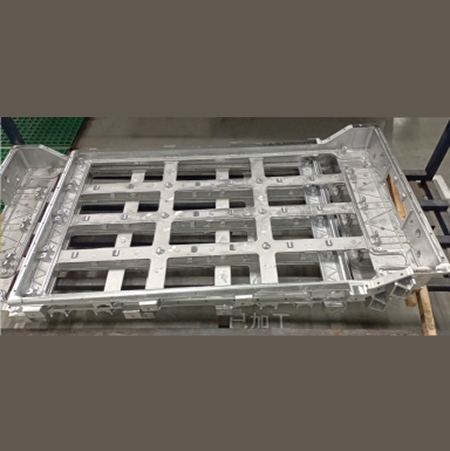

Processing Cases

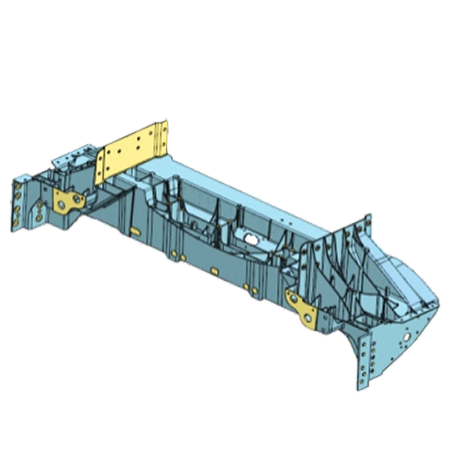

1.Automobile Mould

High Processing Efficiency

One-time clamping of workpiece, 5-axis simultaneous control

Vertical, horizontal and various free angle processing can be completed synchronously

High Material Removal Rate

High speed, high power spindle

High rigidity and high dynamic characteristics of the whole machine structure

High Cutting Feed Rate

XYZ axis high speed drive

High rigidity and high dynamic characteristics of the whole machine structure

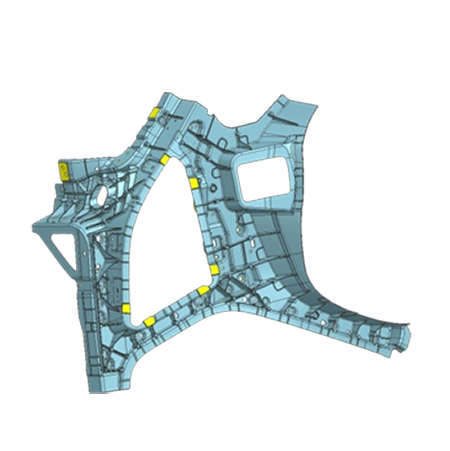

2.Aerospace Structural Parts

Excellent Surface Processing Quality

Five-axis simultaneous cutting application

High-precision processing capability

Greatly Shorten Processing And Polishing Time

Linear motor drive

X/Y/Z axis high-speed drive

High Precision

High-speed, high-power spindle

High rigidity and high stability of the whole machine structure