factory customized Twin Turrets Cnc Lathe - Center Drive lathe For Thin-walled tube – Oturn

factory customized Twin Turrets Cnc Lathe - Center Drive lathe For Thin-walled tube – Oturn Detail:

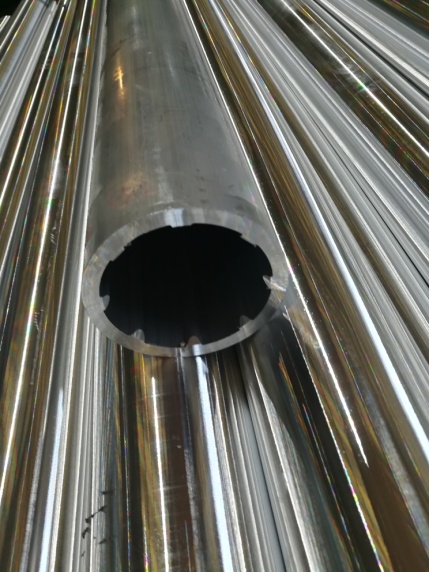

Thin-walled Tube and Tube Parts

Technology Solution

1.Process analysis of processing thin-walled cylindrical parts

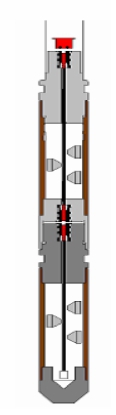

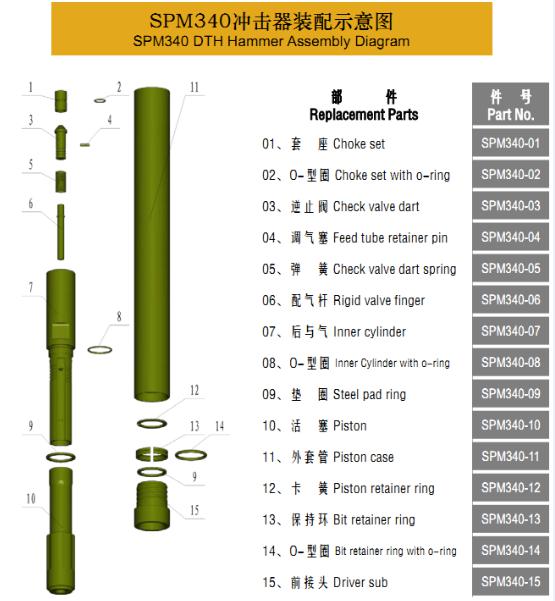

Thin-walled tube and tube parts have always been a difficult point in machining. For example: the perforating gun body of the perforating equipment used in petroleum machinery drilling, the inner and outer shell of the downhole shock absorber, the inner and outer shell of the oil pump protector, the printing drum of printing machinery, the spinning drum of textile machinery, the transmission machinery Conveyor roller, down-the-hole drilling and blasting equipment

The outer casing, etc., of course, also includes the shells of military or civilian bullets.

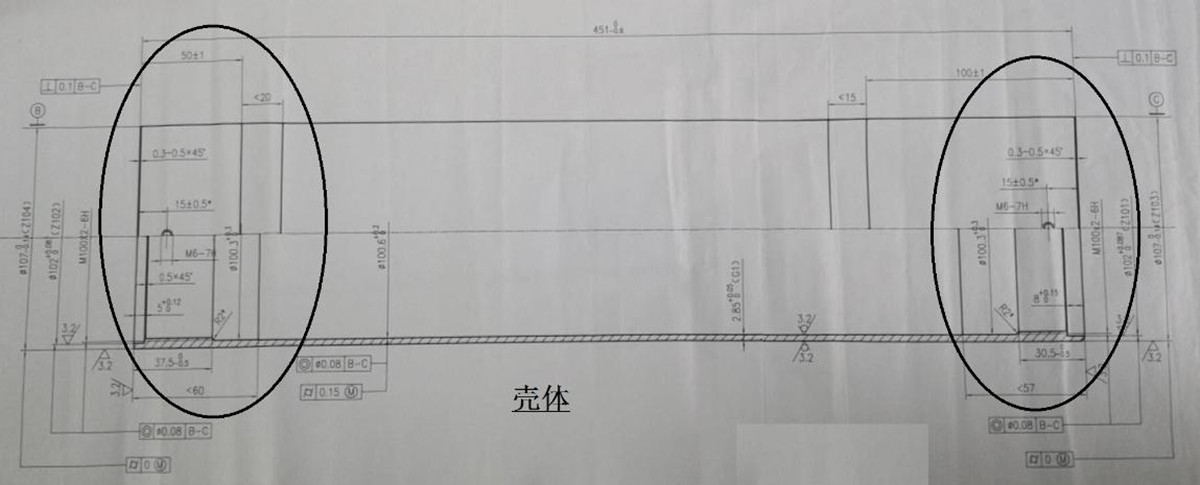

1.1Typical parts

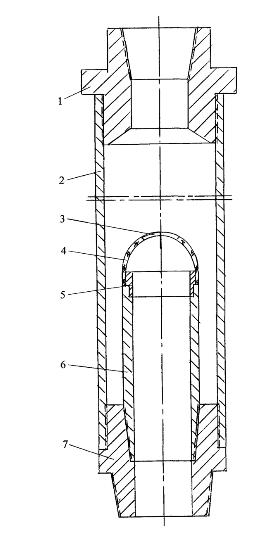

The structure of the perforating gun: the main components of the perforating gun are the gun body, the gun head, the gun tail, the center joint, the detonation accessory, the sealing ring and the cartridge holder. The basic performance requirements of the shooting gun. As the main bearing part of the shaped energy perforator, the most basic performance of the perforating gun is its mechanical strength. Only when its mechanical properties are met, can the shaped energy perforator be guaranteed Possibility and safety during downhole perforation.

Oil pump protector

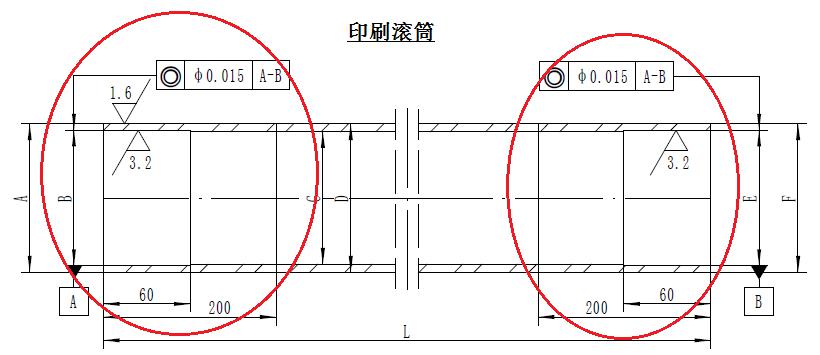

Printing cylinder

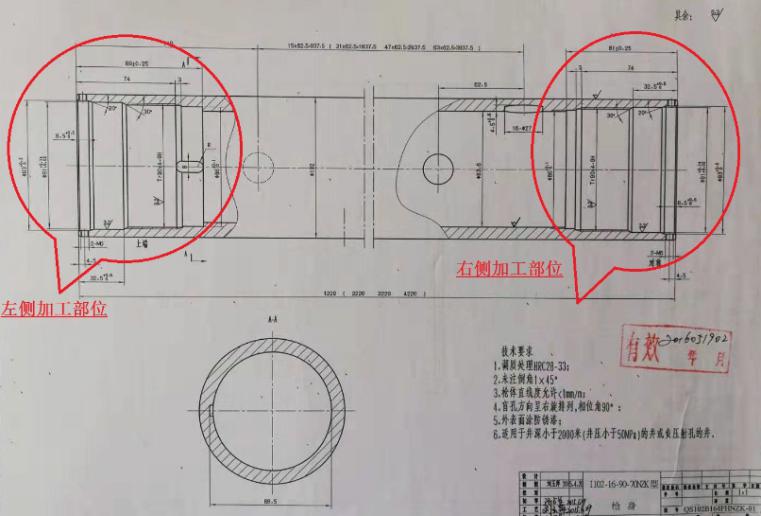

Comparison of new and old impactor shell processing technology

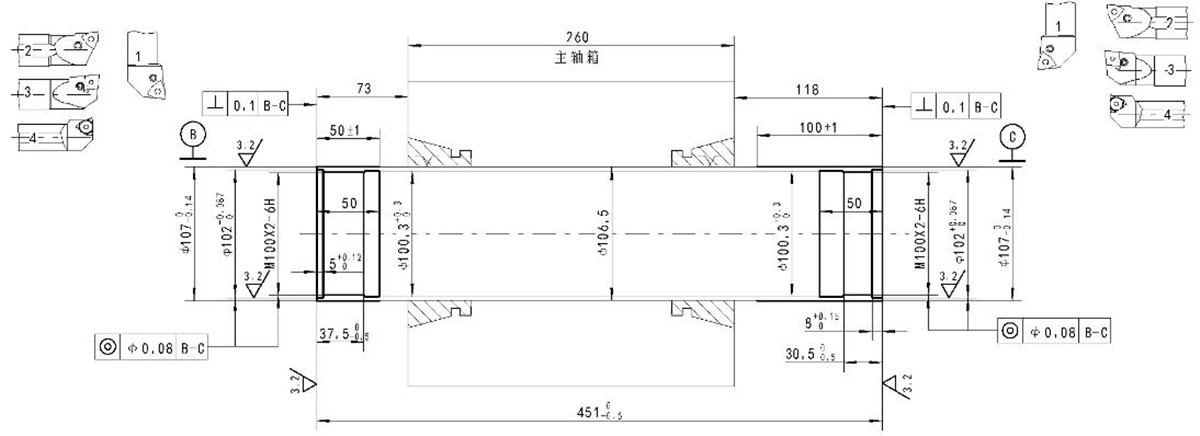

This type of parts has one thing in common: thin-walled pipes formed by rolling or spinning are mainly processed at both ends, inner hole stop (for assembly), inner hole thread (for connection), a little outer circle, outer thread (if Required), inside and outside empty sipes and chamfer

1.2. Process analysis.

1) Traditional processing technology:

Generally, one end of the lathe is used for clamping, and the other end uses the tailstock to top the inner hole and the center frame of the car, then use the center frame to support, and then fine boring the inner hole of this end, the end face of the car, and the machining that may be required for turning the outer circle Parts, or the clamping parts required for turning and turning.

Workpiece U-turn: inner support or outer clamp cylinder body, tailstock tightening the workpiece, car center frame socket, center frame support, re-boring inner hole, car end face, outer circle.

If the coaxiality of the inner holes at both ends of the cylinder is slightly higher, the processing may be repeated many times.

2) Using double-end CNC lathe processing technology:

The processing of the above content can be completed in one clamping, and both ends can be processed at the same time, which not only reduces the number of machine tools, but also shortens the process flow and material handling, and greatly improves the production efficiency. Since both ends are processed at the same time, the coaxiality of the workpiece is also reliably guaranteed.

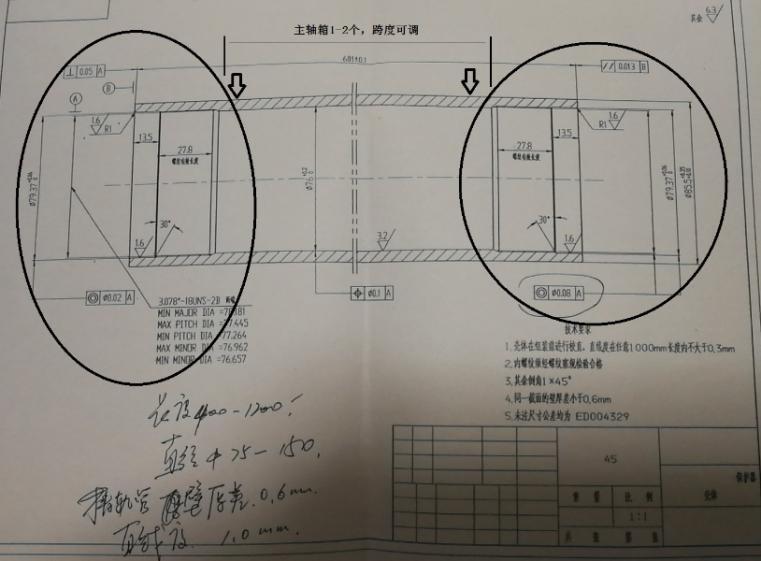

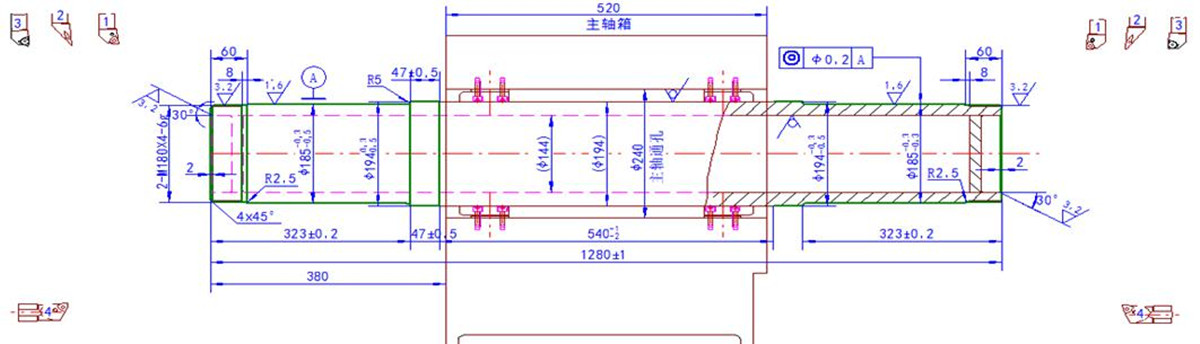

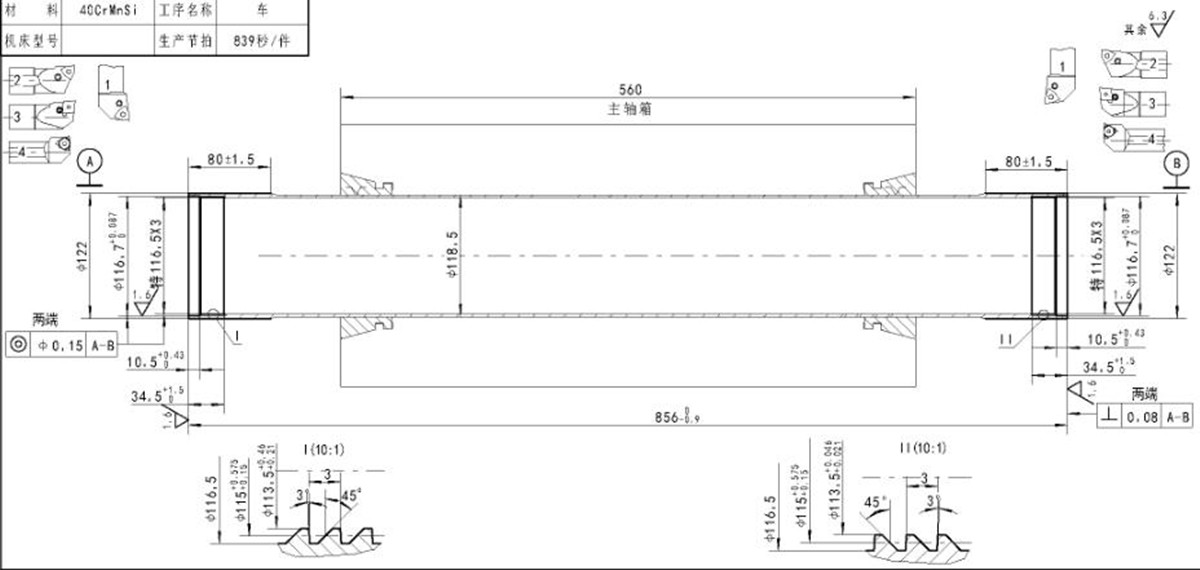

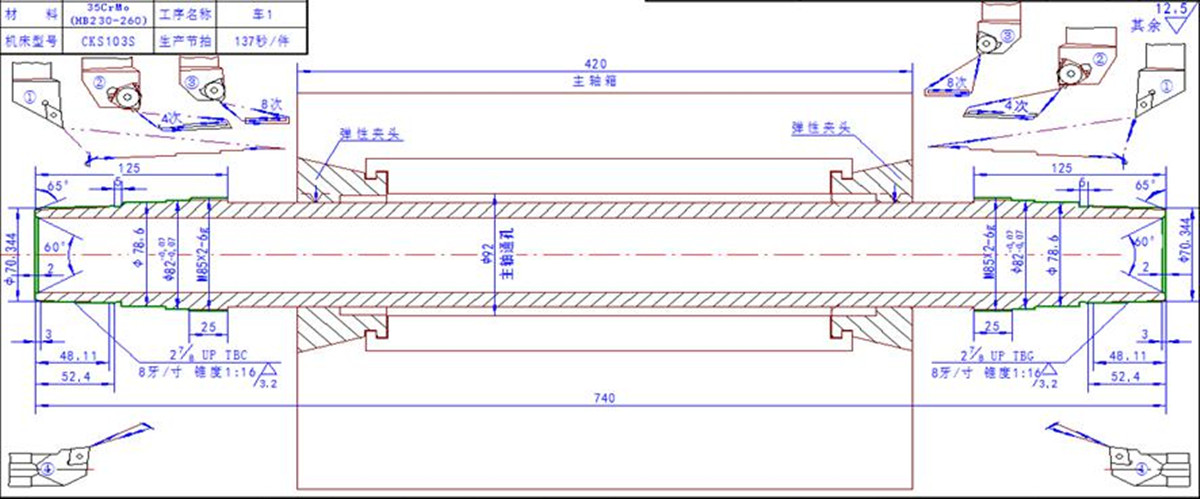

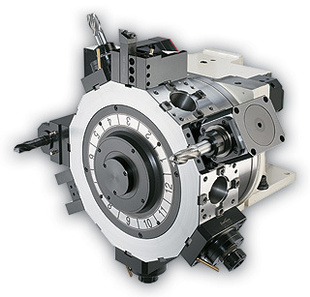

Specifically: depending on the length of the workpiece, one or two headstocks can be used to clamp the outer circle of the workpiece. The clamping diameter and clamping width of the headstock are determined according to the diameter and length of the workpiece. Two 8/12-station rotary turrets Simultaneously process the end face, inner hole and outer circle at both ends. As the number of tools that can be installed is sufficient, it can meet the one-time processing needs of complex parts.

If the external clamping part of the machine tool in this sequence needs to be processed, then use a machine tool to double-top the inner holes at both ends of the workpiece to turn or grind the external circle.

There are also customers who use a centerless grinder to grind the outer circle in advance, and then use the double-end CNC lathe to process the inner holes and end faces at both ends to the process requirements.

3) Cases of cylindrical parts processed by double-end CNC lathes:

①Processing printing machinery cylinder, select SCK208S model (using double spindle box).

②The SCK309S model (single headstock) is used for processing the car’s central axle.

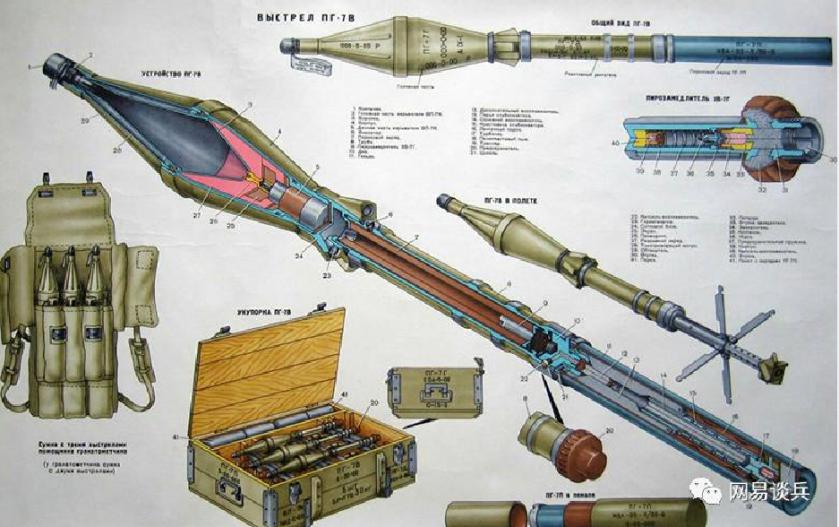

③SCK105S model is used for processing military thin-walled tubes.

④For processing military thin-walled tubes, select SCK103S model

⑤ SCK105S model is selected for processing oil pipes of petroleum machinery.

SCK Series Double-end CNC Lathe Introduction

■Double-end surface specialized CNC lathe is a kind of high-efficiency and high-precision advanced manufacturing equipment. It can simultaneously complete the outer circle, end face and inner hole of the two ends of the workpiece in one clamping. Compared with the traditional process of clamping the parts twice and turning around, it has the advantages of high production efficiency, good coaxiality and high precision of the processed parts.

At present, there are more than 10 types of models, clamping diameter: φ5-φ250mm, processing length: 140-3000mm; if it is specially considered for tube shell parts, the clamping diameter can reach φ400 mm.

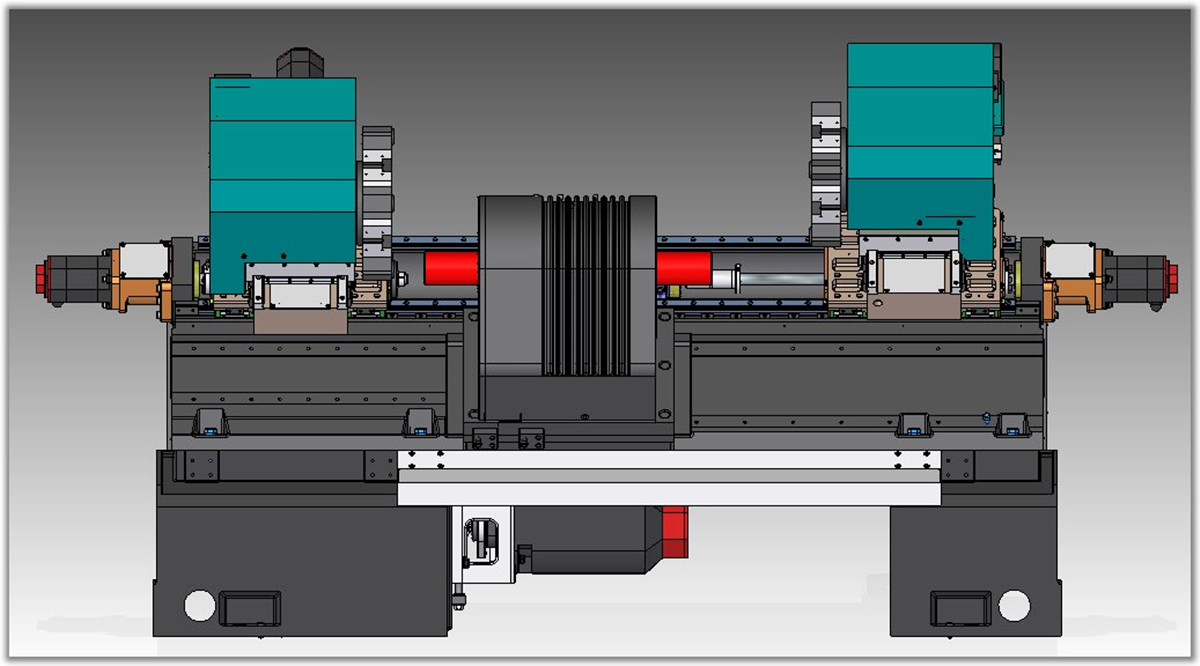

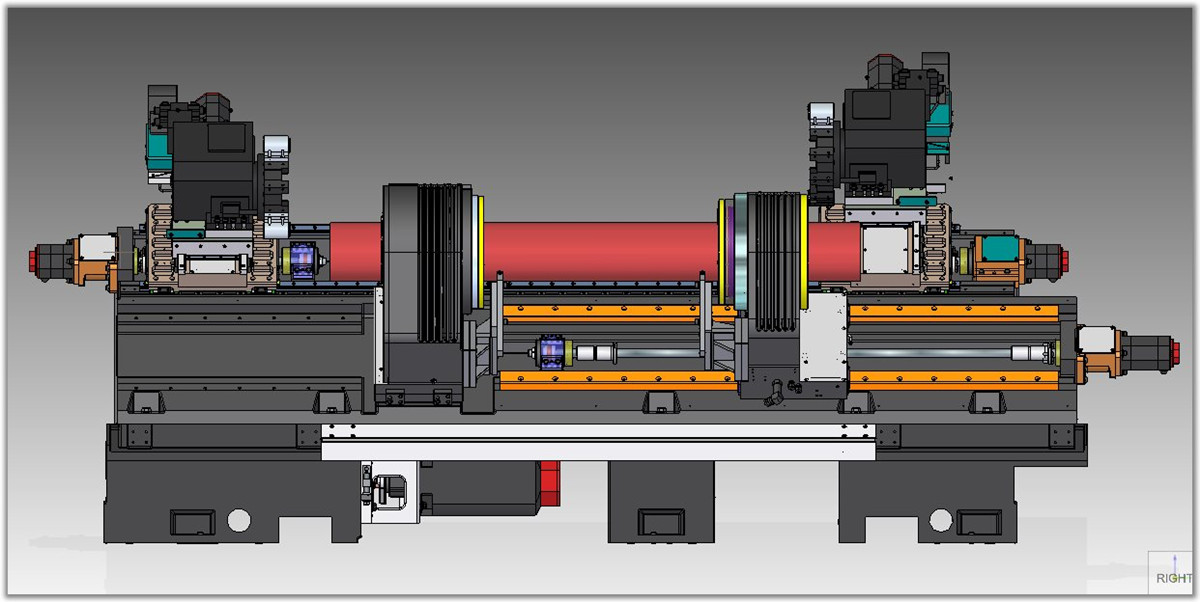

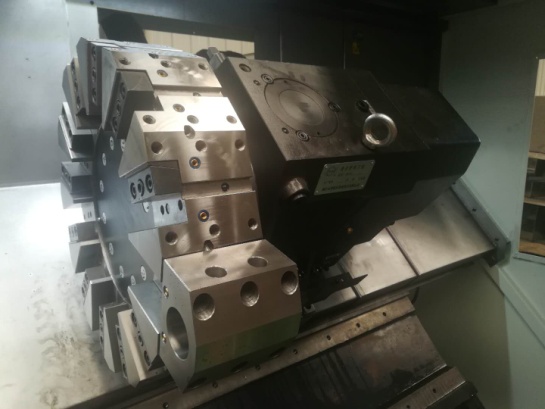

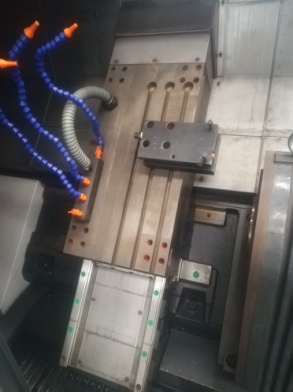

■The whole machine has 450 inclined bed layout, which has good rigidity and convenient chip removal. The spindle box with intermediate drive and clamping function is arranged in the middle of the bed, and two tool rests are arranged on both sides of the spindle box.

■Using a dual-channel control system, the two tool rests can be linked with the spindle at the same time or separately to complete simultaneous processing or sequential processing of both ends of the part.

■Each servo feed axis adopts high-quiet ball screw, and the elastic coupling is directly connected, with low noise, high positioning accuracy and high repeat positioning accuracy.

■According to the processing length of different workpieces, 1-2 intermediate drive headstocks can be equipped. Among them, the left main spindle box is fixed, and the right sub spindle box is driven by the servo motor to move the ball screw in the Z direction. It can only use the main headstock to clamp to complete the processing of short parts; it can also use two headstocks to clamp together to complete the processing of long parts.

![]()

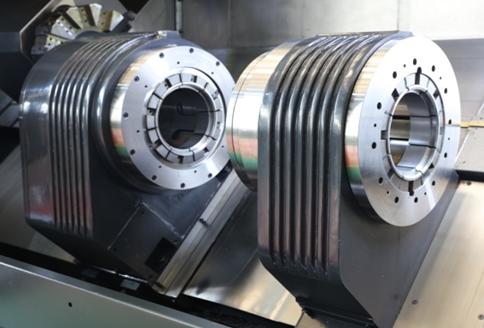

■The spindle box integrates the five components of the spindle system, clamps, clamping cylinder, oil distribution system and driving device, with compact structure and reliable operation. The clamping devices are all hydraulically driven, and the clamping force can meet the needs of the maximum turning torque.

■ Fixtures are installed in the spindle box. The structure of the fixtures includes a collet type with a middle clamp and two ends clamp, and a middle clamp and two ends clamp jaws.

In view of the easy deformation characteristics of clamping thin-walled cylindrical parts, collet clamps are usually used. The clamps are driven by the cylinder piston to make them elastically deform to realize the chuck loosening or clamping. The deformation of the elastic chuck is 2-3mm (diameter) . The chuck clamps the clamping part of the part in the entire circumferential direction, the clamping force is uniform, and the deformation of the part is small. When the surface accuracy of the part clamping part is good, there will be a high clamping accuracy. At the same time, it is essential to reduce the deformation of the parts to make the parts have a proper overhang.

■When the parts have a large diameter specification, the adjusting claw can be installed in the chuck structure. The adjusting claw is a soft claw, which is fixed on the inner diameter of the clamp. Before use, it has high clamping accuracy and quick and easy replacement.

■The machine adopts a modular design, and can have a variety of structures, configurations and functional combinations according to user requirements. There are many options for the tool post, such as row tool type, turret type and power turret. The two tool rests can be linked to the spindle at the same time or separately to complete simultaneous or sequential processing of both ends of the part.

Tool holder combination: double tool holder; double row tool; power tool holder; left row tool+ right tool holder; left tool holder + right row tool.

■The machine tool is fully enclosed and protected, equipped with automatic lubrication and automatic chip removal devices, with good protection performance, beautiful appearance, easy operation and convenient maintenance.

■The machine tool can be equipped with a supporting frame, an auxiliary device for loading and unloading, and an automatic loading and unloading device. See the video and machine photos.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.