Drilling And Tapping Compound Machine

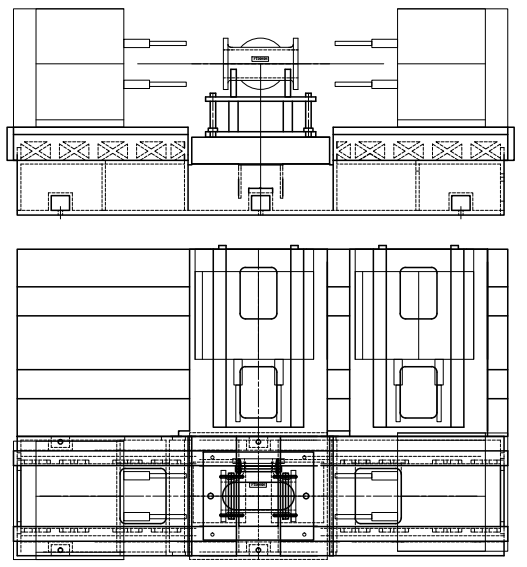

This machine tool is a horizontal CNC three-side drilling and tapping integrated machine tool. The left and right heads are composed of hydraulic mobile sliding table and gear box; the third surface is composed of CNC mobile sliding table and gear box (divided into two groups: drilling and tapping). The middle is composed of workbench, hydraulic fixture and other parts, and is equipped with independent electrical cabinet, hydraulic station and centralized lubrication device. The workpiece is manually lifted and hydraulically clamped. See the mechanism schematic for details.

Workpiece processing standard process:

①The machine tool is a positioning process, one piece at a time, which requires a reference surface to be used as the installation positioning reference in the previous process.

②The standard process is: clean the workpiece-put the workpiece to be processed into the tooling-hydraulically clamp the workpiece, the three sets of work slides can be fast forwarded and attacked, and the three sets can be synchronized or processed in steps, and the three sets of slides are fast Retreat to the original position-the middle mouth tapping slide moves to the position, and the tapping is processed. After the processing, the tapping slide returns to the original position-hydraulic release-manual loading and unloading-enter the next cycle.

The tooling adopts the outer circle positioning of the valve body blank, and the hydraulic cylinder on the upper part of the workpiece presses the workpiece.

Application

This machine is mainly used in processing Valve, Pump body, Auto parts, Construction machinery parts etc.It can work for many procedures,for example, End face hole , Median orifice, Bore-hole and Sphere.It worked with Huadian PLC Controller, It can realize automation, high precision, multi variety and mass production.

Main features

(1)This machine worked with Huadian PLC Controller, it can work for many procedures,for example, End face hole , Median orifice, Bore-hole and Sphere. It’s CNC Controller has good compatibility, powerful function and easy operation.

(2)The Feed Sliding table guideway use high quality gray cast iron,trough rough casting, tempering and aging treatment by three times. Fully eliminate the residual internal stress, The surface of the guide way adopts super audio quenching and the hardness is up to HRC55. Through high precision guide way grinding processing, to ensure the accuracy, rigidity, stability.

(3)The transmission part adopts precision ball screw and interpolation to eliminate the gap,to ensure the machine drive steady.

(4)The power head is equipped with three - stage manual speed change with powerful motor,achieve low speed but high torque, can withstand heavy cutting load, improve processing efficiency.

(5)The working equipment adopts Hydraulic pressure-automatic clamping, to improve efficiency and reduce labor intensity.

(6)The machine adopts Centralized lubrication, to ensure that the full lubrication of each moving parts then improve the service life of machine tools.

Primary structure

Our machine is mainly composed of body, power head,CNC feed sliding table,working equipment,and equipped with an independent electric cabinet, a hydraulic station, a centralized lubricating device, a cooling automatic chip remove device, and a high protection device.

(1) Body

The Body adopts integrated casting body with high quality, trough manual tempering and aging treatment by three times. The surface of the guide way is treated by super audio quenching, the structure is reasonable,to ensure rigidity, precision and the stability of the machine.

(2) The power head

The body of power head is adopt excellent casting,spindle use material 20GrMnTAi,with forging, tempering, carburizing and quenching, high precision grinding out and in. The bearing adopts NN30 series high precision double row cylindrical roller bearing to ensure the rigidity and precision of the spindle.

(3) The Fixture

The Fixture is special designed for workpiece. The positioning block and positioning pin are quenched,to ensure the reliable positioning of workpiece. Hydraulic clamped the workpiece, to improve processing efficiency, reduce labor intensity.

Hydraulic pressure equipment

The hydraulic station adopts the independent Superposition valve, which is composed of a high quality electromagnetic valve, a pressure regulating valve, a throttle valve and a double vane pump. And equipped with air cooling device to ensure that the hydraulic station has normal oil temperature when it works.

Electrical cabinet

The Electrical cabinet is independent and closed.Installed with CNC controller, Inverter and electrical components.Also set air cooling device to ensure that the electrical components of the machine work properly, no dust.

- Main parameters:

Max.drilling diameter(mm)

6-12

Working table(mm)

360×400

Left/Right travel(mm)

480

Vertical travel(mm)

220

Drilling spindle speed

580

Travel(mm)

230

Taper hole of Spindle(NA)

7:24

Motor power(KW)

2.2

Tapping spindle speed(mm/min)

256

Horizontal Travel(mm)

300

Taper hole of spindle(NA)

7:24

Max.tapping(mm)

8-M14

Hydraulic station motor(KW)

1.5