Deep Hole Drilling Machine

1.Machine features:

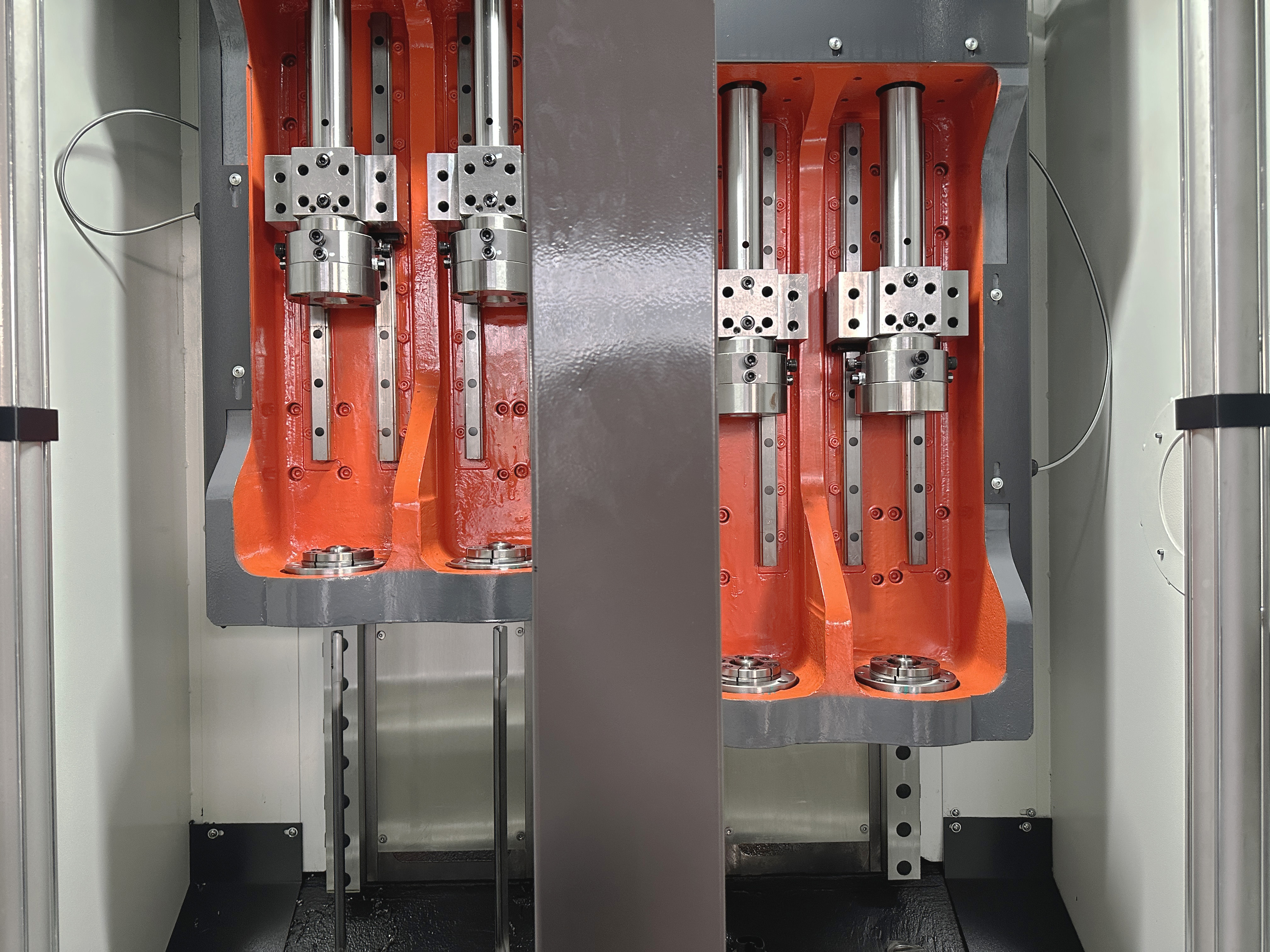

Innovative inverted structure For workpieces with a hole depth of less than 700mm, it has the characteristics of smooth chip removal,good tool rigidity, and high processing efficiency.

Flexible adaptation to diverse tooling solutions

1.1.Drilling from bottom to top for smoother chip removal

The innovative inverted structure allows the workpiece to be fed from bottom to top after clamping, making the chip removal process smoother and doubling the processing efficiency.

1.2.Up to four stations for easier processing

According to different workpieces and different customer needs, four models of single-station, double-station, three-station, and four-station are provided to make processing easier.

1.3.Diversified tools, more flexible adaptation

Various tools such as gun drills, U drills, BTA drills, sleeve drills, and oil hole drills can be flexibly selected according to different requirements.

1.4.Deep drilling without eccentricity make the surface smoother

The workpiece is clamped and fixed by hydraulic control, resulting in higher processing consistency and better inner hole finish.

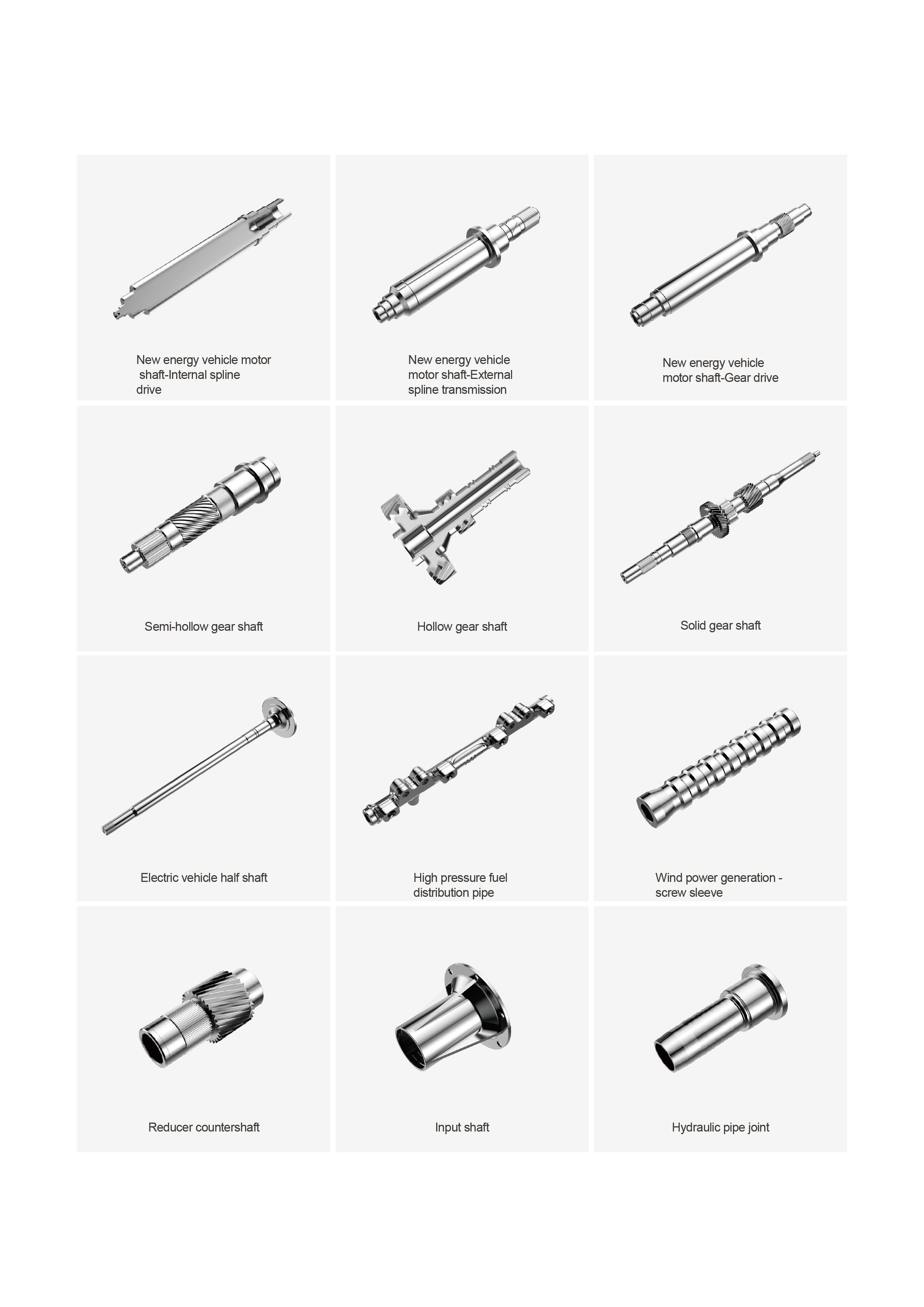

2.Main workpieces of double-end lathe series

3.Technical specications

| Name/Model |

Processing diameter (mm) |

Processing length (mm) |

Station number |

Roughness(μm) |

Centrality (mm) |

| ZS 300-500L/1-12 |

1-12 |

300-500 |

1 |

0.4-3.2 |

0.1/10 |

| ZS 300-500L/10-20 |

10-20 |

300-500 |

1 |

0.4-3.2 |

0.1/10 |

| ZS 300-500L/18-30 |

18-30 |

300-500 |

1 |

0.4-3.2 |

0.1/10 |

| ZS 300-500L/25-45 |

25-45 |

300-500 |

1 |

0.4-3.2 |

0.1/10 |

| ZS 300-500L2/1-12 |

1-12 |

300-500 |

2 |

0.4-3.2 |

0.1/10 |

| ZS 300-500L2/10-20 |

10-20 |

300-500 |

2 |

0.4-3.2 |

0.1/10 |

| ZS 300-500L3/1-12 |

1-12 |

300-500 |

3 |

0.4-3.2 |

0.1/10 |

| ZS 300-500L3/10-20 |

10-20 |

300-500 |

3 |

0.4-3.2 |

0.1/10 |

| ZS 300-500L3/18-30 |

18-30 |

300-500 |

3 |

0.4-3.2 |

0.1/10 |

| ZS 300-500L3/25-45 |

25-45 |

300-500 |

3 |

0.4-3.2 |

0.1/10 |

| ZS 300-500L4/1-12 |

1-12 |

300-500 |

4 |

0.4-3.2 |

0.1/10 |

| ZS 300-500L4/10-20 |

10-20 |

300-500 |

4 |

0.4-3.2 |

0.1/10 |